|

Good clients, who pay construction companies fairly and on time, who have recurring work, and are well organised, are like gold to construction companies and should be nurtured and looked after. I’ve done many multi-million dollar projects for the same customers, and in some cases projects have gone from a first phase to a second one and even onto a fifth phase. Many of these projects have been negotiated with the client avoiding the uncertainty of having to tender on the open market. When they were tendered we were sometimes awarded the project even though we didn’t have the lowest price.

So how do you keep a good client? Of course you cannot keep competitors away from a client by price alone. There will always be someone who is prepared to undercut prices to get an opportunity to work for a good client. The only way to keep competitors out is by: 1. developing a relationship with the client 2. delivering a quality product, on time and without incident 3. being fair and honest with the client 4. acknowledging mistakes and rectifying the problems as soon as possible 5. managing the client’s expectations 6. not over-promising and under-delivering – if anything under-promise and over-deliver 7. senior management from the construction company being seen by the client on the project 8. project staff (in particular the contractor’s project manager) understanding the importance of building the relationship This shouldn’t stop you from submitting construction claims and variations when you are entitled to do so. But, do ensure these are fair and that they are discussed with the client and that, where possible, you have assisted and forewarned the client to try and prevent the variation from occurring. In many cases, despite submitting and being paid large variation claims I have maintained good relationships with these client and have gone on to do further projects with them. If a competitor’s price is cheaper than yours, explain to the client why your bid is more expensive. Remind your client of your past successes and achievements on their projects. Negotiate with the client, but don’t undertake a project at a price that will lose money. Naturally, when a construction company does repeated work for a client there’s a danger they’ll become complacent and arrogant, and start to charge inflated prices for work. When a client discovers they’ve been taken advantage of they can be quite unforgiving. Don't depend on only one client Don’t become overly dependent on one client. Unfortunately clients also go through phases of spending and other times when they cut back on expenditure. Contractors who are largely dependent on work from one client can quickly run out of work when that client stops spending. Stay in contact When work finally runs out with a particular client due to another contractor winning the work, or the client not having further construction projects, stay in contact with them. This may entail a phone call every six months and as a minimum a greeting card at the end of the year. No matter how good the relationship was with the client you cannot depend on them remembering your company in a year’s time and inviting the company to tender for their next project. Regrettably clients have fairly short memories (except when it comes to remembering poor performance), so it’s essential to keep reminding them of the past relationship. (Paul Netscher is the author of the acclaimed books ‘Successful Construction Project Management: The Practical Guide’ and ‘Building a Successful Construction Company: The Practical Guide’. Get your copies from Amazon or other retail outlets, in your choice of paperback or eBook. This article is an extract from ‘Building a Successful Construction Company’)

6 Comments

Having the correct type and numbers of construction staff (Section Managers, Supervisors, Engineers, Contract Administrators, etc) on your construction project can be the key to its success.

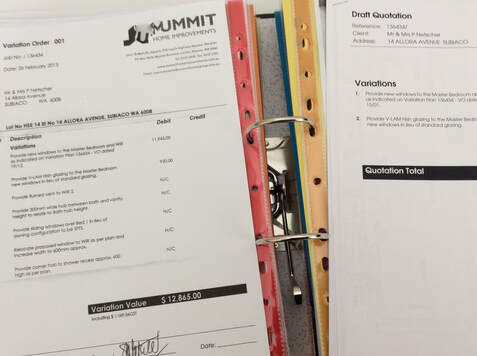

The risks of having the incorrect staff I’ve sometimes been guilty of under-staffing my construction projects. The risk with that is: 1. if a member of staff falls ill or resigns there’s nobody who can take on an additional roll 2. tasks are rushed because people don't have sufficient time because they are doing too many things at once, resulting in mistakes and items being overlooked 3. staff work under pressure, and long hours, which may lead to them resigning Obviously having too many staff leads to: 1. higher project costs which were not allowed for 2. staff becoming unhappy due to boredom and feeling underutilised Obviously having staff with the wrong skills or those that don't have the required experience can also create major problems Factors that affect a construction project's staffing requirements The numbers of staff and their positions on a construction project depend on a number of factors, such as the: 1. number of construction work areas – each work area may require its own Supervisor 2. numbers of workers required to complete the work – there is often an optimum number of workers that a supervisor can look after 3. available skills of the construction workers – if the workers are poorly skilled or inexperienced they usually require more supervision to ensure they perform their tasks correctly and safely 4. complexity of the construction project – more complex projects may require more Engineers and Supervisors while a project which is simple or has lots of repartition may be easier to manage 5. relative locations of the work areas and their distance apart – travelling between different work areas can make Supervisors time unproductive or mean workers are left standing waiting for instructions when the Supervisor is on another distant part of the project 6. client requirements – some clients specify the minimum ratio of Supervisors to workers, while others may dictate that they require dedicated individuals to specific tasks, even though the contractor wouldn’t normally have a dedicated person 7. contract reporting requirements – some clients and project managers may require elaborate and detailed regular reports which can be time consuming for the contractor to prepare 8. skills and experience of the available staff – more experienced staff may be able to supervise a larger work area with more workers 9. project schedule (or programme/program) – fast-track construction projects of high intensity may need more supervision 10. quality and experience of the client and their design team – projects where the client has to be assisted, or where information is late or of a poor quality often require more input from the contractor, and projects with multiple claims and variations may require additional contracts administration staff Staff numbers also depend on the different skills and disciplines required. For instance in the civil industry Supervisors may only be skilled in earthworks, while others are skilled in concrete works, electrically orientated, or more suited to building trades. If you can employ a Supervisor skilled in a multitude of disciplines, there’s often a reduction in the number of staff required. To assist with calculating staff requirements prepare a project organisational chart. This shows the different levels and types of management required, the reporting structures, as well as the different roles and responsibilities. In addition the chart could indicate whether the staff are required full-time or shared between projects, and if they are Head Office or site-based positions. Remember also that if the project has to work nights, or weekends, additional staff will be required to supervise and manage these shifts. Conclusion It’s necessary that careful thought goes into correctly staffing your construction project to achieve the best balance of efficiencies and costs. In Australia for instance, the cost of a Supervisor is not much greater than some craft workers, so it may pay in some cases to have more supervision just to improve the efficiencies of the workers. Once you have determined the number and types of skills required you can begin sourcing the best people to fill the positions. This is a topic which I will deal with later. (Paul Netscher is the author of the acclaimed books ‘Successful Construction Project Management: The Practical Guide’ and ‘Building a Successful Construction Company: The Practical Guide’. Both books are available in paperback and E-book from Amazon and other retail outlets. This article is adapted from his book ‘Successful Construction Project Management’) In my last 3 posts ‘Construction project variations – have you included all your costs’ (Read more), ‘Understanding the real cost of delays on your construction project’ (Read more) and ‘Are you working for free on your construction project’ (Read more), I discussed the reasons for delay claims and scope changes and what costs could be included when construction companies submit their claims for these changes and variations. However, a construction variation claim could be rejected by your client if it doesn’t include all the correct and required information. Winning change orders requires effortI have seen many poorly put together variation claims or change orders. Some for millions of dollars, yet construction companies seem to think that they can apply minimal time and effort to formulating their variation claims. That it will be easy money! The client will pay their variation claim – they just have to! Some even delegate their construction claim preparation to junior inexperienced quantity surveyors or contract administrators. Sometimes the construction project manager isn’t even aware a claim has been submitted and is blindsided when their client takes offence to a spurious or unsupported claim. Should construction project managers take the lead with variation claims? Some of these claims are poorly thought out and presented. I’ve seen claims with arithmetic errors, spelling mistakes (even incorrectly spelling the client’s name), factual errors, contradictory information, confusing language and unsupported evidence. Consider how hard a contractor has to work to earn ten thousand dollars, or even a million dollars, so why then do some construction companies expect to spend minutes, or an hour, preparing a claim for the same amount. Construction companies should ensure that a knowledgeable and experienced person is allocated to draft the claim (familiar with the contract, the client and the work that’s been done) and that it is reviewed and checked by the project manager before it’s submitted. What to include in your construction change orderWhat to include A properly drafted and well thought out claim will be hard for your client to refute and it’s likely to be successful. To increase your chances of a successful claim here are some points to consider. Claims should have: 1. a description of the event 2. the cause of the event 3. the date of the event, where relevant 4. the impact of the event 5. steps taken to mitigate the impact 6. the cost and time impacts of the event 7. all supporting documentation attached, or should refer to supporting documentation correctly referencing the relevant contract clause numbers, construction drawing numbers, schedule or program item numbers, correspondence, Bill of Quantity items or construction contract specifications as required It’s essential that this supporting documentation is relevant to the claim, supports the claim and is not contradictory (any contradictions must be explained as part of the claim). As part of formulating the impact of the event all calculations and schedules should be included. The claim schedule should reference the approved contract schedule. Calculations should reference where the facts and figures came from and how they were put together. The calculations should be checked for arithmetical errors (which can occur all too frequently). Remember to include all of your legitimate and claimable costs (as discussed in my previous articles). It’s usually difficult to add in extra forgotten costs after you have submitted your claim. It’s unprofessional and will annoy your client. It may even cast doubts on the legitimacy of your original claim. Do not surprise your client with the change orderNotifying your client The client must be notified of variations as soon as the contractor becomes aware of them, and certainly within the time specified in the contract. Failure to do so may mean the contractor loses their right to claim. The claim must: 1. be lodged within the time-frame specified in the contract 2. be addressed to the correct person 3. be delivered to the correct address It’s often a good idea to discuss large or contentious claims with the client before submitting them. This not only forewarns the client the claim is coming, but also provides an opportunity to discuss the reasons and the merits of the variation. Also ensure the client is aware that you are willing to discuss the claim and answer any questions they may have. I use the word ‘discuss’ and not ‘negotiate’. To indicate that you are willing to ‘negotiate’ gives the idea that you have built fat into your claim and that not all the costs are legitimate, which will immediately put your client on their guard and they will already doubt that your claim is legitimate or accurate. Ensure your change order is approvedConstruction variation claims that are clear and concise, and which have facts which are supported and can easily be justified are often agreed and settled with clients with little effort. Once contractors get a reputation of submitting inflated or bogus variation claims it can become difficult to convince the client when a reasonable and just construction variation claim is submitted. Of course a variation claim can be more easily supported if the contractor has maintained accurate documentation during the course of the construction works (like Daily reports), communicating regularly with the client, and has taken all reasonable steps to prevent the claim from arising. Of course contractors must also understand their contract documents (your construction project contracts - why you need to understand them) #constructionvariations #constructionprojectmanagement #contractors © 2022 This article is not to be reproduced for commercial purposes without written permission from the author.

Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Many construction projects lose money when construction companies pay their workers more than they are due. In other cases workers are paid less than they should and they become demoralised or demotivated, which impacts their productivity and can even lead to industrial action including work stoppages.

Project Managers must read and understand the industrial relations agreements governing their construction project. These may include the prevailing labour legislation and project, union and company agreements. Employees’ wages and conditions must be in accordance with the relevant agreements which often differ between projects. Many construction projects incur additional costs because they don’t manage the hours and pay of personnel correctly which could be because: 1. the hours personnel work aren’t recorded correctly 2. people aren’t paid the correct overtime rate or the rate is applied incorrectly 3. people aren’t booked absent when they’re not at work 4. leave forms aren’t submitted (including annual and sick leave) 5. people are paid the incorrect rates 6. deductions for tax aren’t applied correctly and in accordance with the latest legislation 7. the incorrect deductions are made from their pay 8. people are paid allowances they aren’t entitled to 9. rates of pay or allowances aren’t adjusted when personnel are transferred to another project 10. people deliberately falsify their attendance 11. errors are made when completing time sheets 12. people leave work before their shift is complete, yet they are paid the full shift (From the book ‘Building a Successful Construction Company: The Practical Guide’ by Paul Netscher. Available from Amazon and other retail outlets) As discussed in my earlier post ‘Are you working for free on your

construction project’ (Read more) most construction projects have changes and variations which contractors have to undertake. Contractors need to claim for the additional costs associated with this extra work. The variation work usually has to be priced before the work is carried out. Unfortunately some contractors don’t price these correctly which means that they could be out of pocket. Other contractors try and be too clever, focussing on how they can make their claim as large as possible, even inventing costs. Yet, these same contractors forget to recover some of the actual costs they are entitled to claim. In my post ‘Understanding the real cost of delays to your project’ (Read more) I discussed some of the costs that delays cause to projects. Below are potential costs that should be considered when formulating other construction variations. Variations could include: 1. Construction labour costs including: a. the base wages b. overtime c. non-productive time such as paid breaks, travel time, time to prepare hazard assessments, inductions, and so on d. allowances e. statutory levies such as for training f. leave pay, bonuses, sick leave, pension, and so on g. personal protective clothing h. personal small tools i. accommodation (if applicable) j. travel (where necessary) 2. construction material costs including: a. the actual material cost b. transport of the material to the construction site c. offloading and handling d. protection and packaging e. quality procedures and tests f. wastage due to breakages and cutting g. cutting (unless this has already been included in the labour cost) h. fixings i. royalties j. insurances k. duties and taxes 3. construction equipment including: a. hire costs b. unproductive time c. mobilisation and demobilisation costs d. insurances e. fuels and lubricants f. wearing parts such as cutting edges, drill and moil points g. maintenance h. supporting vehicles such as fuel and service vehicles i. attachments and ancillary items 4. demolishing existing structures including: a. loading and transport of waste materials b. temporary supports and bracings c. dump fees d. protection of finished work 5. supervision and management costs including: a. the basic salary b. allowances c. leave pay and bonuses d. accommodation and transport e. computers and mobile phones 6. off-site staff such as Contract Administrators, and Planners 7. project insurances and sureties 8. costs of permits 9. profits and overheads 10. access equipment 11. office and facility hire 12. additional security 13. protection of existing and completed structures 14. additional design and drawing costs 15. subcontractors’ costs including the contractor’s mark-up It’s also important to assess the effect the variation has on the schedule which may result in: 1. the overall project duration being extended 2. the variation impeding or delaying other works 3. the variation requiring resources from other tasks which then impacts on their completion dates 4. in some cases the overall project may be delayed and push the work into an unfavourable weather season such as winter or heavy rainy periods Although it’s important to ensure that are captured it’s also petty to be claiming for a kilogram of nails on a one thousand dollar variations, or to be adding in every cent, which can be time consuming. Some of the costs may also already be covered elsewhere in the contract. Remember too that the client will often request a breakdown of how you calculated the cost of the variation so ensure that you are able to justify all of the costs. Good record keeping is an essential aid to proving your costs. Sometimes clients may insist the variation is priced according to existing rates or other similar work. You may then have to ensure that these existing rates will cover all of your costs. If they don’t you may be able to justify to the client reasons why the existing rates shouldn’t apply. You usually have one opportunity to include all the costs in your variation and it’s difficult, unprofessional and embarrassing to ask the client for more money after your variation has already been accepted by them. So get it right first time. (Adapted from the book; ’Building a Successful Construction Company: The Practical Guide’ by Paul Netscher. Paul has also written the popular book ‘Successful Construction Project Management: The Practical Guide’. Both books are available from Amazon and other retail outlets) The construction Project Manager (site manager) should provide guidance as to the quality requirements and expectations on the construction project. Whenever they travel around the construction site they should be looking with a critical eye at both the completed work, and the work under construction, to ensure it conforms to the project’s quality requirements.

A top-to-bottom commitment is required for quality. A construction project will not achieve the required quality standards if individual workers are not committed to producing a quality product. At the same time, even if the workers are committed and well-trained, the project will not achieve the desired quality if the Supervisors, Quality Engineers and the Project Manager aren’t committed to producing a quality product. All workers and staff must take responsibility for producing the best quality product possible. Often on projects I see people blaming their tools, materials, equipment, the schedule, the Supervisor, or fellow workers for a poor quality product. Each individual must understand that they are personally responsible for the quality of the product they produce, and they shouldn’t play the ‘blame game’. In saying this, management must also be mindful of how they influence the quality of the workmanship on the project, and what they can do to improve the quality culture, like sending craftsmen or Supervisors on appropriate training courses. They should also continually look at the construction process with a critical eye, to see if changes would improve the quality of the end product. Maybe the construction materials or equipment are genuinely substandard making it difficult for the workers to achieve the desired quality. On many construction projects I see completed quality work being damaged by follow-on trades and contractors. All workers on the project should not only take pride in their work, but also in the work done by the others, and they should respect each other’s work. Taking a little extra care while working around completed work, and protecting it, will ensure it’s not damaged. There should be a clear delegation of the ultimate responsibility for the quality of a task. Often I’ve had Engineers, or Supervisors, tell me that they weren’t responsible for the poor quality of their section of works and that it was the Quality Manager who was responsible. Obviously this is rubbish! Each construction Supervisor is responsible for everything within their section of works, including the quality of work and the materials used. Every section Engineer should be responsible for the quality of their section of the works. The Quality Engineer, or Quality Manager, is appointed to assist the Supervisors and section Engineers to monitor and record the quality, and to ensure the required quality systems are implemented and followed. Poor quality construction work should not be accepted, and construction Project Managers must not pass by substandard work without taking action. This action may be to simply chide the responsible party for minor defects, but with serious breaches of quality, consideration should be given to implementing disciplinary procedures against the parties responsible. (From the book 'Successful Construction Project Management; The Practical Guide' by Paul Netscher) |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed