|

From time to time contractors have to demolish existing structures, either completely or partially, to enable new structures to be built. This work is inherently dangerous, and if it’s not done correctly could result in the remaining structures or surrounding property being damaged, and even people getting injured or killed. Usually, large demolition work must be done by licensed contractors, but often projects involve smaller demolition works which are tackled by less experienced people. In fact, sometimes contractors have to demolish newly completed work because the work was substandard of poor quality and didn’t meet the project specifications because the client changed their mind, or the designer made a mistake. Some of these demolitions are done with little forethought and planning, sometimes with inappropriate equipment, often done hurriedly so that impacts to the construction schedule are minimised. To prevent accidents it’s important that certain precautions and steps are implemented before any demolition work begins. These include:

This article was first published on the ClockShark website. To visit this website and continue reading the article click on the link above.

Please share this post To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below: 'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Management: From Project Concept to Completion' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you

45 Comments

A study by PwC of public contracts in 8 countries in the European Union in 2010 identified that the direct public loss encountered due to corruption in public contracts accounted for 18% of the overall project budgets concerned, of which 13% can be attributed to corruption and 5% due to mismanagement. Imagine, for every dollar spent 18 cents disappeared. A $1 million project will cost an on average $200,000 extra. In the US the FBI places public corruption as one of their number one priorities, even though the US is considered to be the 18th least corrupt country in the world. Unfortunately, corrupt practices occur throughout the various construction project phases and can be perpetrated by any of the project stakeholders. This corruption is due to direct and deliberate corrupt practices as well as mismanagement. Mismanagement of construction projects occurs far too frequently. I’m sure we can all relate stories of theft, corruption, fraud, and mismanagement that occurred on a project. I’ve previously related a story of how half a million dollars of cement was stolen from one of my projects. Whether you are a project owner, an investor, project manager or a contractor it pays to be vigilant to avoid corruption on your project. Not only does corruption result in someone realising less value, but it can also impact reputation, and even result in fines and prison time. Being vigilant together we can prevent corruption and fraud. Corruption, fraud, and theft on construction projects can be perpetrated by: Owners

....Continue Reading.... This article was first published on the ClockShark website. To visit this website and continue reading the article click on the link above.

Please share this post To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below: 'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Management: From Project Concept to Completion' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you  The quality, level and type of fencing and security on a project are dictated by numerous factors, including the client’s requirements, the location of the project, existing security and fencing around the project and the level of security risk, as well as the likelihood of a member of the public having unrestricted access to the project. In addition, local councils often have bylaws which stipulate the type of fencing or hoardings. These barriers may be simple fences, through to solid barriers of timber, tin, steel or even concrete. Many construction projects are constructed in operational facilities, close to neighboring properties or in busy public places. It’s necessary to erect barriers which may be needed to:

This article was first published on the ClockShark website. To visit this website and continue reading the article click on the link above.

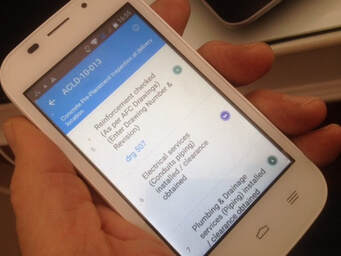

Please share this post To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below: 'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Management: From Project Concept to Completion' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you  Taking photographs on a construction project is very useful for a number of reasons. Photographs of the project taken regularly, which includes the date and time, are beneficial in tracking progress. Photographs can also be used to document variation work, such as; the depth of rock excavations, or the extent of demolition work. Photographs showing depths, levels or size may require an object, or tape measure, to show the scale, while in others it can be useful to include the particular machine, or piece of equipment, working on the variation. Photographs are important to record safety incidents. These should be taken immediately after the incident occurred, before the site has been disturbed too much, and should include the date and time. Photographs can be used to discuss potential design or quality problems on the project with designers who aren’t stationed on the project construction site. In addition, photographs can be used to record problems on the project, such as; lack of access, or the client’s operations or other contractors impeding the work, or damage done by others to completed work. Photographs of subcontractors’ poor quality work or lack of safety compliance provide a record which can be sent to their management. It is becoming more common to include photographs with punch lists and quality inspections. Most specialized checklist software makes provision for the inclusion of photographs. Photographs record that the item was checked and meets the quality requirements (especially items that will become covered up) and they also record defects which allow those rectifying them to more easily find the fault. Photographs are an important aid to record the condition of structures when a pre-construction survey is prepared, or when an area or structure is handed to the following contractor. When hired equipment arrives on the project it’s good practice to photograph it to record the condition. These photographs should have a date. Photograph damaged items and the condition of tires and wearing parts. Many suppliers photograph deliveries to record that they have been delivered to the designated address. Damaged materials should be photographed so there’s a record of the damages and these photographs should be immediately sent to the supplier. Depending on the project, photographs may be used for news stories, annual reports, and advertisements, and to show managers and stakeholders project progress. Care should be taken to check that these photographs don’t show unsafe work practices, an untidy workplace, poor quality or sensitive information since this could provide negative publicity. Sometimes photographs in company portfolios need to be changed or trashed. Frequently I see companies with pictures that are clearly out of date with old equipment. Ensure your company portfolio has pictures of your latest projects. Often it even pays to engage a professional photographer to take project photographs for company publicity, advertisements, and portfolios. Of course always ensuring that these show the best side of your project. Many professional bodies and even construction magazines hold annual construction photographic competitions. Having one of your projects feature amongst the finalists can be prestigious and good advertising for your company. In our company, we even arranged an annual photographic competition with the 12 best photographs featuring in a company calendar which was distributed to projects and clients. The added benefit of this was that the company received excellent photographs of the latest projects which could feature in advertisements and the company portfolio. Consider adding some photos of similar projects to your next quotation or price submission (not too many, only a couple). Of course, make sure the photos are relevant. Photographs of finished projects can even be useful to include in your personal résumé. Caution Some projects may be sensitive or be using specialized equipment, which the owner might not want competitors to see. ....Continue Reading.... This article was first published on the ClockShark website. To visit this website and continue reading the article click on the link above.

Please share this post To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below: 'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Management: From Project Concept to Completion' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you  I do some work for a non-profit organization. Recently the national office decided to adopt a new accounting software package. This was done with little consultation with the branches, and in particular with the people who were actively involved with their finances. Each branch of the organization has its own requirements and way of doing things. Now it is important to standardize systems wherever possible so that every branch or division in the organization operates the same way, but for this to happen it is necessary to understand how each branch operates and their particular requirements. Then make sure that the new system can accommodate these requirements where possible. This may require the system to be adjusted slightly. It also might mean that the way some things are done at each branch or division has to change. It is however important that the new system won’t negatively impact the business unit. Things haven’t gone very smoothly with the transition to the new accounting system and the national office has succeeded in upsetting our branch treasurer and others. Thousands of words have been written in emails and much has been said about who is at fault and who is right. I’m sure all of us at some time have been part of an organization where new software, technology, and systems have been adopted, only to find that they didn’t deliver as expected, or that they weren’t used and eventually were discarded. Inevitably this has resulted in wasted costs and wasted time, even in some cases resulting in personnel who are annoyed, demoralised, or in some cases have left the organization. So why have these systems failed, and why is implementation often done so poorly? What should we consider when implementing new systems and technology? The implementation of new technology can often benefit the company, enabling it to be more efficient and productive. However:

There are many different systems available and their prices vary enormously. Therefore, before deciding on a system it’s important to adequately research the various options, decide what you require from the system, look at where the company will be in a few years’ time (size, location, and type of projects), and consider the pros and cons of each system and how they’ll best suit the needs of the company in the future. Decisions must not be made solely on price, rather they must be made considering the benefits of the system and the ease of use. ‘Clunky’ systems often take time to use, don’t always give the desired results and end up annoying users. Implementing new systems is time-consuming and often those implementing the system will have to work additional hours while learning new ways and to input existing data into the system. The implementation can also be disruptive to the overall running of the business. Invariably there will be ‘bugs’ and issues that have to be resolved. Often management underestimates the time and effort involved in converting to new systems and invariably unrealistic deadlines are set. Often these deadlines result in shortcuts being taken, existing data not being converted properly and ‘bugs’ not being properly solved. This can lead to long-term problems that can have negative impacts on the efficiencies of the system later. It is important to have deadlines otherwise some parts of the organization are slow to convert, but meeting a deadline should never impinge the long-term effectiveness of the system. Deadlines might have to be reassessed. Monitoring implementation is critical to ensure it’s done properly and is progressing according to schedule. Those in the organization needlessly delaying the implementation may have to be given a push in the right direction. It is important to have a ‘champion’ to drive the process who is continually talking to those involved to understand problems and progress. Issues need to be swiftly resolved before they become a reason for some not to implement the system, or reason for employees to become disgruntled. Management should show appreciation to that personnel who have been involved in converting to the new system and those that have had to put-up with the disruptions. Why new systems fail .....Continue Reading..... This article was first published on the ClockShark website. To visit this website and continue reading the article click on the link above.

Please share this post To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below: 'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Management: From Project Concept to Completion' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed