"We are often quick to criticise employees for poor work, but we overlook thanking or praising them for a job well done." Try saying these 12 important things on your construction projectNo this isn’t an English lesson, but rather a reminder of some phrases we forget to use, or are too nervous to use in our construction business. Here are a few things we forget to say, or don’t say often enough. Could you be guilty? 1. “Hello” (“Good morning”) – Do you greet employees when you pass them. I knew one business owner who would walk right by people in the office every morning without greeting them. We shouldn’t be surprised that these employees found this hurtful. As managers we are often preoccupied with problems and phone calls and I’m sure I’ve been guilty of not greeting employees. But that worker on your construction project will feel recognised and appreciated if you say hello next time you walk-by. That simple act of recognition, which cost you a few seconds, can make your employees feel more included and appreciated and more motivated. 2. “Thank you” (“Well done”) – We are often quick to criticise employees for poor work, but we overlook thanking or praising them for a job well done. Praise can be motivating. A simple thank you doesn’t cost anything and yet it can reap big rewards. 3. “Help” – You can’t always be expected to solve every problem. Sometimes you have to ask for help and advice. You don’t have to use the advice, but just discussing the problem with someone else can provide a new perspective. Many projects sink further into trouble because project managers have been too proud to ask for advice and have continued on making poor decisions until the project becomes irrecoverable. We all need help sometimes. 4. “Let’s check” (“Are you sure?”) – Too often mistakes are made which simple checks could have detected. Mistakes with prices and quotations, mistakes with measurements, even mistakes in letters and emails. Take a few minutes to check what you’ve done and you may just avoid a costly or embarrassing mistake. 5. “Is that safe?” – Most accidents are preventable and if those involved had stopped to ask this simple question they would probably have done things differently and avoided the accident. Don’t kill yourself or others because you didn’t stop and ask; “is this safe?” Why should we take construction safety seriously? 6. “Is there an alternative?” (“Can we do it differently?”) – We often accept the first solution without considering alternate methodologies, alternate solutions or alternative materials. There are usually many ways of doing something - more than one may be right - but we should always be looking for the best solution. It may be time for the old dog to learn some new tricks. The way you’ve always done something may no longer be the best solution anymore. 7. “Will we be paid for that?” (“Did we allow for that?”) – I’ve found that contractors often do work for free. Sounds unbelievable! Yet project managers sometimes don’t read the contract so aren’t aware of the basis of the quotation and what the client’s obligations are. They are also sometimes guilty of performing extra work without a written instruction. When you receive an instruction, or open a new construction drawing, ask the question; “did we price to do that work? Will we be paid?” Are you working for free on your construction project? 8. “I don’t understand” (“Can you clarify that”, or “I’m not sure what you mean”) – All too often we make assumptions when we aren’t sure of something. This is particularly dangerous when pricing a project when the request for pricing isn’t clear. It can be very costly when you incorrectly assume something. I’ve encountered many problems on my projects when drawings weren’t clear and people assumed something which in fact was incorrect. Don’t be too proud to ask questions – no question is too stupid, especially when the answer could save money, and even sometimes lives! Just as important is to not assume that the person you are giving instructions to understands what you are saying or knows what you want. The Contractor's Duty to Ask Questions 9. “No” (“Sorry we can’t do that because;…” or, “Sorry we can’t do that but maybe we could do this;…”)– I’m sure we’ve all accepted a project schedule that’s too short, or been bullied by a customers into giving a discount or reducing our price to fit their budget. We’ve probably lamented these actions later when we finished the project later than the agreed date, or lost money on the project. Maybe we’ve regretted not saying no to an unsafe act? Employees and customers can be demanding and it’s often easier to say yes when they ask for special treatments or exceptions, yet this may lead to more demands and problems later. Of course we shouldn’t get into the habit of only saying “no”. I’ve known people whose first response was always “no” – “no” can sometimes be over used and destructive. Learn to think before you say “no”. If you do say no it’s often useful to offer an alternate solution, or at least give reasons for the negative response. 10. “We should do it like this because; ….” – Sometimes we expect our crews to blindly follow our orders and rules. Safety is a prime example where companies and customers seem to have endless rules and regulations. On some projects there is often a culture of non-compliance of these rules. But, maybe if our employees understood the cost of their non-compliance, the potential implications to their and their fellow workers safety and health, they might just be more inclined to do the correct thing. It’s time we stopped saying: “you do it this way because those are the rules”, or “that’s the way we do things around here”, or “that’s what the boss says”, or “it’s my way or the highway”. Your crew deserves the respect to know why we should do things in a certain way, and understanding the reasons will probably make them more likely to do as requested. Explaining why we do things in a certain manner is also part of the mentoring process. 11. “Are we proud of that?” (“Am I proud of this?”) – Many quality problems arise on projects because of a lack of pride or a lack of care. Will you accept the quality of the item in your house? Will you be proud to show your work to your family? Our customers are paying for a quality product and we should be committed to delivering it to them. Does anyone give a …. anymore? 12. “Let’s celebrate” – Construction isn’t an easy business and there are numerous problems encountered on a daily basis, so when there’s a substantial success embrace and celebrate it. Everyone wants to belong to a successful team – success is empowering, infectious and motivating. "Everyone wants to belong to a successful team." Good Communication is Essential for a Construction Project ManagerHow many of the above words and phrases do you use? A large part of construction management is about managing and motivating people. Good communication is essential. Don’t be too proud or arrogant to use certain phrases. Take a few extra minutes out of your day to use some of these phrases and you would be surprised by at the results you get on your projects - they could just save you millions and earn you a whole lot more respect from your crews. Does your manager forget to use some of these phrases? How does that make you feel? Do you regret not saying something you should have? Good communication is essential in construction Please share this post This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app Please share this post Learn more about Construction Project Management"Very useful guide regarding the management of the construction projects. Open, direct and insightful." To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author.

1 Comment

Construction project logistics - the hidden bottleneck that could be strangling production26/6/2016 "Poor logistics will be costly on your construction project." Logistics are often overlooked when planning a construction project, yet poor logistics can cause bottlenecks which literally strangle the life out of your project. It impacts production and productivity causing delays and adding to costs. Usually the larger the construction project the more important and complicated the logistics become. Getting materials, equipment and people to the construction work siteLogistics includes mobilizing people to the project site, getting them to the project every day and then moving them around the project to where they are working. A project with a dozen, fifty or even hundred people can be simple to coordinate, but some projects can have thousands of workers. Sometimes the project may be in an operating facility which already employs thousands of workers. Somehow the construction workers have to get to their job site without impacting the owner’s workers. Then the owner’s workers still have to get to where they are required without hindrance or being endangered by the construction work. This must happen safely and quickly. Even if every person in a hundred person team is only delayed by five minutes in the day, the total impact on the project is more than 8 hours – put simply we have to employ an extra person every day to make up for the lost time. Five minutes on most construction projects is nothing and it’s often more like fifteen or twenty! Why is there poor productivity on your construction project? Some industrial and mining facilities can cover huge areas and the distanced between work locations can be significant. Lengthy delays in getting personnel to their work areas at the start of the days and after their rest breaks can reduce productivity dramatically. Then there are facilities that have extraordinary security that causes huge delays. I have for instance worked in diamond plants and precious metals refineries where security has been very strict and getting materials and equipment in and out of work areas took time, patience, paperwork and effort – tying up staff and disrupting progress and productivity. Vertical transportation in high-rise buildings can be particularly challenging. I’m sure we have all experienced frustrating delays on these projects waiting for hoists to take up men and materials, or cranes to lift materials to where they are needed. Logistics is about getting materials and equipment from their point of origin to where they are needed at the work face at the correct time and without damage. Logistics includes offloading the equipment and material safely, and installing them when required. Do Your Material Deliveries Suck? How to avoid problems Some material and equipment can be over-sized – either being extra wide, long or high or very heavy. Special transport may be required as well as permits and escort vehicles. Can the roads leading to the project site handle these loads? Are the roads on the project site designed for these loads? We need to consider radii of bends, road widths, height restrictions and weight restraints. In addition projects are changing on a daily basis and routes may become restricted or even dug up. What could be a simple exercise of getting an item onto site at the start of the project can turn into a nightmare later as structures are built and roads are changed. Many contractors have suddenly found routes unsuitable part way through the project when new bridges were built over the road restricting the height of loads that can use the route. planning deliveries to construction sites Construction Cranes"Projects frequently don’t have sufficient cranes or material handling equipment." Projects frequently don’t have sufficient cranes or material handling equipment. This lack of equipment not only delays getting the materials to where they’re required but could also delay offloading the trucks bringing the material to the project. These delays impact productivity, delay trucks from returning to collect the next load (meaning more trucks are required) and can lead to additional costs from transport companies whose trucks are delayed. Double handling and even triple handling of materials is a result of materials being off-loaded in the wrong place, or materials arriving ahead of time and the work area isn’t available. The additional handling of the materials results in additional costs but it can also risk damaging materials and equipment. Lifting operations need to be done safely with trained personnel. Improperly rigged loads can cause accidents resulting in injury and damage to equipment. Lifting operations can be delayed because of wind, equipment breakdowns, inexperienced operators, poor rigging and slinging techniques, cranes being incorrectly positioned, repeated moving of the crane between loads or workers installing the equipment and materials not being properly prepared. Too often work areas aren’t ready for items that have to be lifted, leaving expensive cranes standing idly waiting, while other areas are themselves waiting for the crane. Proper organisation and planning of work areas can free up the cranes to do more work. Cranes, lifting equipment and slings Crane congestion can be a major problem – especially on large contracts with many different contractors and subcontractors, each with their own crane. This can lead to dangerous situations which need to be avoided such as the risks of crane booms clashing and cranes lifting loads over workers. At the very least it leads to reduced productivity. A major part of logistics is about getting the right item arriving on the project site at the right time. We need to ensure that suppliers have a delivery schedule which they stick to. Far too often we receive the materials we require last before the items we require first. This leads to a congested work area and double handling of materials. Storing materials on construction projectsOften projects don’t consider the laydown areas where materials will be stored before they are needed. These areas may have restricted access. Sometimes they aren’t cleared and leveled properly which could lead to dangerous situations when trucks and cranes are parked on sloping ground. This might result in them overturning. Materials stacked on sloping ground could also over topple causing damage and even serious injury. These storage areas need to be well drained so stormwater can drain away. I have seen storage areas flooded resulting in damage to the materials or at best the material storage area couldn’t be accessed until the water was drained away. Storage areas also should be firm underfoot so that trucks, cranes and the materials don’t sink into the ground. Crane outriggers sinking into the ground can lead to dangerous situations of the cranes overturning. Materials must be stored in such a way that they don’t become damaged by the elements or contaminated. Materials must be easily accessible and when necessary so the oldest materials can be used first. "Construction materials must be easily accessible." Good logistics are important for the success of your construction projectMany contractors don’t plan their project’s logistics well resulting in delays to the project, additional costs and in some cases even damages to materials. Contractors sometimes just place an order for an item of equipment or materials required for the project without considering how the items will get to the project, how they’ll be off-loaded, where they’ll be stored and how they’ll be installed. Well thought out logistical procedures and plans will pay dividends to your project. 10 reasons your project is behind schedule (programme) This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app Please share this post Learn more about Construction Project Management"It is a very easy to use book with guidelines that are referenced intelligently with case studies." To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author. "Is your construction company doing as well as it used to?" Is your construction company doing as well as it used to? Is it performing as well as it should? Can your construction projects be better managed? Are you losing customers? Does your construction company have spare capacity? What’s the reason for the fall in business? No doubt you are blaming the poor economic climate, more competitors, competition from overseas, the lack of skilled resources and the government. We can always find an excuse if we look hard enough – even the weather can be blamed! Prevent poor weather from disrupting your construction project But have you actually taken a good hard look at how your construction business is run and managed? Is the company still the same as it was last decade, or maybe even last century? The construction world is continually changing around us. Technology is evolving. Our new employees have different skills and expectations. Customers are changing and their needs are different. Trends come and go – what customers were paying for 10 years ago is no longer desirable. What are you doing about it? Many managers are so busy dealing with everyday problems on their construction projects that they don’t notice these changes around them. When they do wake up to what’s happening it’s too late and customers have deserted them, their competitors have overtaken them and their construction business is losing money. Contractors have to adapt and change. It’s no good saying “this worked for me 10 years ago” or “we have always done things this way”! Some contractors think they can simply go through a re-branding exercise to improve business – which they think means changing the company logo and corporate colors. Maybe even adding a catchy tag-line! The center of the city where we live has been dying over the last 5 years. The streets which used to be vibrant and full of activity late into the night are almost deserted at 9pm. Businesses are closing down. The city council have now, at great expense, launched a re-branding exercise to brand the city center as vibrant and exciting. But it isn’t! They haven’t changed anything in the city. So what’s this re-branding exercise achieved? People fooled by the re-branding into going into the city center at night can only be disappointed. You have to change your construction company from within and bring on a new strategy. "Those considering a career as a construction manger or becoming the owner of a construction company - would benefit immeasurably by reading this great book." Reader on Amazon 10 Steps to making your construction company great10 Simple changes you can take to make your construction company more successful.

"What does your construction equipment say about your company?"

"When your clients aren’t satisfied with quality they’ll take their future business elsewhere."

Now is the time to make your construction company more successfulInstead of being totally focused on the day-to-day managing of your company take time to visit your construction projects. Look at them with new eyes. What can be improved? Is the quality and safety acceptable? Are your employees motivated? Are your customers Happy with your company’s performance? Look around you and see what your competitors are doing. Read articles to learn what customers are doing, and to see new building innovations and construction equipment. Be open to criticism and more importantly be open to change. Change can be challenging, exciting and motivating. Maybe call in outside help, because new experienced eyes and ears, which aren’t tainted with past baggage, will view things differently to how you do. Let’s make your construction company as successful as it should be. 10 Questions To Ask That Will Make You A Better Contractor Learn more about Construction Project Management"A page turner for those wanting to raise their game and truly express the essence of a Construction PM. The industry appreciates your effort Paul!" To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author. Good employees are critical to the success of your construction project in more ways than one14/6/2016 "Your employees are more than just workers, they can be a valuable asset in many other ways to." Many managers only see their employees as workers – simply there to do a job. But our employees are usually more than this, and even more so in construction. Why employees are more than just workers on your construction project.Yes, we employee people to do a job, to fill a roll, to complete their tasks diligently, safely and to the required quality. But is a carpenter only good for building things from timber and is that Supervisor only good for supervising a team on our construction project? You may be surprised how their actions, both on and off the construction site, can help, or hinder, contractors.

"Your employees should be real assets on your construction projects. Look after them right and get the best from them." Your employees can damage or add value to your construction companySo next time you look at an employee don’t just see them as a worker, a carpenter, a concreter or an iron worker - rather see them as an asset that can add value to your construction company. Embrace them and treat them fairly. Make them proud of their company. Let them know how their actions can damage or add value to the company. Building a successful construction company isn’t just the responsibility of the owner or senior managers – it demands teamwork and commitment from everyone. We depend on good workers in more ways than we usually consider. Employing the right people in construction Learn more about Construction Project Management"This book helps with practical tips learned from real experiences. A must read book for the people who are involved in construction projects, especially project managers." To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

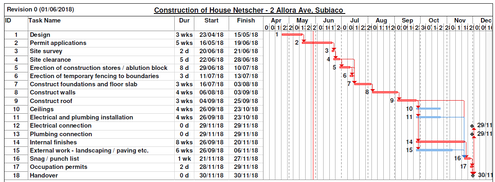

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author. "A good construction schedule is essential to the success of every construction project." I find construction schedules invaluable on all of my projects. For small projects they could be simple hand drawn bar charts and for large construction projects they could consist of thousands of linked tasks created using specialist software such as Primavera, Microsoft Project, Candy or similar. Why are construction schedules important?Construction schedules are useful because:

"A properly planned construction schedule will avoid clashes or hold-ups on the project" Common errors with construction schedulesSome of the more common errors include:

"This book helps with practical tips learned from real experiences. A must read book for the people who are involved in construction projects, especially project managers." Construction schedules are essential to contractors and project ownersPreparing the best workable construction schedule or construction program is an art, a science and one that needs expertise and experience. The schedule needs to reflect how the construction team will build the facility, the realities of the construction site, the available resources and skills, the local conditions and the contractual requirements. Committing to a construction schedule which is impossible will cause damage to both the contractor and the customer. Following a schedule with flawed logic will invariably result in a delayed construction project, or even some completed work having to be redone. Ignoring the schedule or not conveying the contents of the construction schedule to those in the field defeats the purpose of preparing the schedule. Construction schedules are useful to contractors and customers and shouldn’t be viewed as just a contractual requirement, or another document for the customer to ‘whip’ the contractor. How you can make your next construction project more successful. This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app Please share this post Learn more about Construction Project Management"Have read two of your books and their practical slant make them essential reading for any budding construction PM, they should be on academic reading lists rather than those dull theoretical PM texts kids are made to read!" To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author. |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed