"Contractors are an eternally optimistic bunch and never seem to allow for any weather related impacts on construction projects." Many projects are completed late so my last two posts focused on project delays. The first; ’10 reasons your project is behind schedule’ looked at delays caused by the contractor and the second post; ‘Is your client delaying your project?’ considered delays created by our clients. Many readers raised bad weather as a major cause of delays. Yes, inclement weather can seriously delay projects, but in many cases should we not have made allowance for some of the weather events? Contractors are an eternally optimistic bunch and never seem to allow for any weather related impacts on construction projects. What, are you really going to work on a twelve month long project and think you won’t encounter rain, winds, summer, and winter at some stage in the course of your project! Changing seasons - is your construction project ready? If you have 500mm (20 inches) of rain in 3 months it will almost certainly disrupt your construction project. But, if the average for that region is 500mm for those 3 months we shouldn’t be surprised and we should have made allowance for rain disruptions in our construction schedule and taken mitigating measures to reduce the impact of the rain on construction work. #constructionschedule "It's professional suicide if you knowingly accept a schedule which doesn’t allow for normal weather conditions." Contractors often put the blame on clients for their unreasonable schedules and say it’s impossible to allow additional time for delays caused by rain – average rainfall which will almost certainly occur! Well that’s professional suicide if you knowingly accept a schedule which doesn’t allow for weather conditions which we can expect in that region during the time you will be constructing the project – weather conditions which will almost certainly occur. Instead of knowingly risking your project and betting against weather events not occurring, even though they happen on average, you might consider taking on the odds at your local casino. Mistakes that impact construction schedules/programmes But some contractors do make their life even harder. Is it possible to at least avoid some of these weather delays? #weatherdelays How does inclement weather impact our construction projects?"Recovering from one hour of rain could take days while we pump work areas dry, clean debris and wait for materials to dry out" Many only see weather disruptions as the direct time lost during the bad weather. Unfortunately some events can cause damage to partly completed structures which could take days or weeks to repair. Recovering from one hour of rain could take days while we pump work areas dry, clean debris and wait for materials to dry out. Adequate insurance can cover us for some of the damages but they usually don’t cover for the delays caused to the project.

Can we mitigate some of the weather delays?"Consider different foundation solutions to minimise excavations which have to be done in the rainy season." There are a number of measures contractors can take to at least mitigate some of the delays caused by bad weather.

Offsite weather can also impact construction projects"Sometimes it pays to keep sufficient stock or get materials in earlier to avoid disruption caused by heavy rains." We should also consider the weather risks to activities happening off-site. Items being manufactured off-site may be hampered by poor weather. Will your supplier be able to continue manufacturing if they experience poor weather? I’ve often suffered delays because suppliers couldn’t paint the items because of wet weather. Choosing an alternate supplier that has covered manufacturing facilities may be more expensive but could avoid the risk of poor weather impacting delivery. Understand your transport networks and how poor weather can disrupt these. Sometimes it pays to keep sufficient stock or get construction materials in earlier to avoid disruption caused by heavy rains. We have had projects cut-off from major centres for days. Construction weather delays are the norm"We can almost guarantee that most construction projects will be impacted by inclement weather." We can almost guarantee that most construction projects will be impacted by inclement weather. In most cases this shouldn’t be an excuse for delays, although unfortunately these days more projects seem to be interrupted by extreme weather events which couldn’t have been foreseen. We can prevent, or at least mitigate many of the delays by understanding the weather patterns in the area and allowing for these expected weather disruptions in our construction schedule. Proper planning can also mean that weather dependent activities are scheduled for times when better weather can be expected. We can also implement mitigating measures to reduce the damage and return the project to full production as quickly as possible. Prevent poor weather from disrupting your construction project Contractors shouldn’t be expected to shoulder the responsibility of extreme weather events or those that couldn’t have been reasonably expected. They should therefore be cautious in accepting contracts where they could be liable for these delays. Much of what I've said seems very basic, yet, almost certainly some contractors won't put bad weather mitigation in place, and their project will be delayed. How has inclement weather impacted your construction project? Are weather disruptions a major cause of delays for your projects? To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author.

13 Comments

"Basic construction management 101." Contractors often make mistakes on their construction projects which almost always cost money, sometimes delay the schedule and on occasion impacts their reputation. Most of these errors should have been avoided – in fact many are basic construction management 101. Unfortunately, because of a shortage of experienced Construction Project Managers we have people managing construction projects who don’t have the knowledge and experience to know better. However, even this shouldn’t be an excuse for some errors, because a little thought should have told them what they were doing was wrong. Often though, these basic errors are caused when experienced Project Managers rush into their projects forgetting the basics, or simply because they were over eager or under pressure to get the project underway. #constructionmanagement #constructionprojects #constructionplanning "Even experienced Project Managers sometimes rush into their projects forgetting the basics," Don’t let these rookie mistakes trip your construction project up.

"By being a little smarter, remembering to do the basics right, we can save ourselves a whole lot of trouble later." Do the basics right and you will save time and moneyNow I’m sure many would say these errors are elementary and they wouldn’t make them. Yet, it’s sometimes surprising the stupid mistakes we all make when we are rushed. But, just as important is to make sure that your team don’t make these errors. By being a little smarter, remembering to do the basics right, we can save ourselves a whole lot of trouble later. The 10 P’s of successful construction project management This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

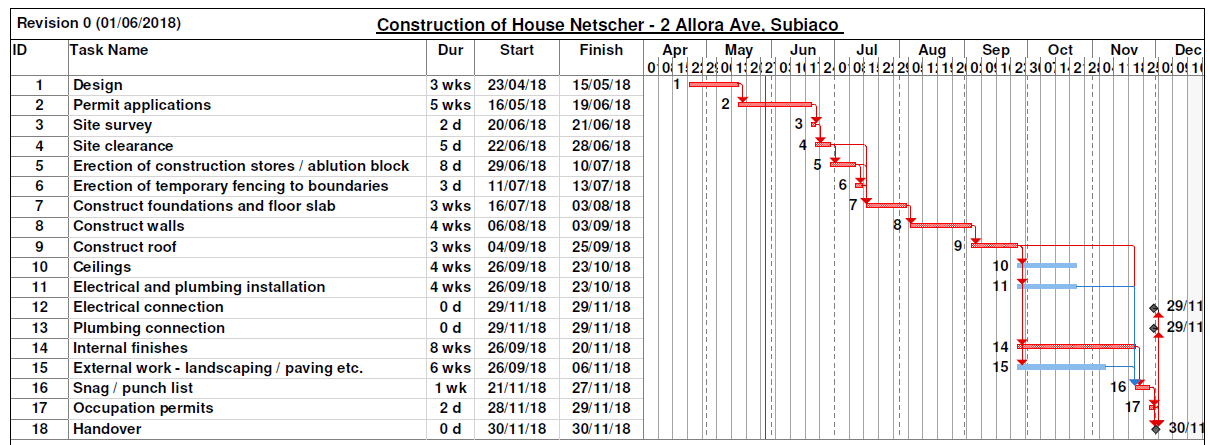

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2023 This article is not to be reproduced for commercial purposes without written permission from the author. "By eliminating these 10 deadly sins you will have a more successful and profitable construction project." It’s surprising how often construction projects don’t go as well as expected. Why is this and what can be done to improve the success of construction projects? I’ve often been asked what contractors should do differently. Here are some items I believe are critical to the success of all projects. See if you agree. I’m sure you can add a few more to my list. I’d love to hear your ideas in the comments below. Do not make these mistakes on your construction project10 deadly sins which impact the success of your construction project 1. Ignoring good safety practices. We have a duty to ensure our employees return home safely at the end of each day. Furthermore, accidents cost money and disrupt construction projects. Unsafe working conditions can result in a loss of productivity and negatively impact the morale of our employees. Accidents happen quickly on construction projects – don’t add another injury to the industry’s statistics or another headline to tomorrow’s newspapers. Ensure your team has the knowledge and equipment to carry out their tasks safely. Don’t accept unsafe practices. Why should we take construction safety seriously? "Don’t accept unsafe practices." 2. Producing poor quality work. Poor quality workmanship negatively impacts your reputation. In addition the cost of rework is enormous and construction industry sources say it could add over 5% to the cost of every construction project. It also causes project delays. Of course, poor quality work can endanger lives should the structural integrity of the facility be jeopardized. Ensure your construction team has the proper skills and equipment to carry out their tasks and that they clearly understand the specifications and the quality expected from them. There is no excuse for poor quality, and we all need to step-up and take pride in our work and our projects. How important is quality on your project? 3. Not training your team. We depend on our team to deliver a quality construction project safely, efficiently and on time. Do they have the necessary skills to do so? We continually hear moans that we cannot get the skilled people we need. We often have to pay inflated wages and salaries to obtain particular skills which are in demand. Yet, what are we doing to overcome this skills shortage? Are we training the next generation of workers for our company and the industry? I’ve always found training to be an essential component to my construction business. Trained, skilled employees are an asset. But more importantly providing training to employees is good for their morale and helps with employee retention. Train and mentor your team – it will pay dividends. Training and mentoring in construction "We depend on our team to deliver a quality project safely, efficiently and on time." 4. An unplanned construction project. Planning starts before we set foot on a construction project. It involves deciding the most suitable construction methodology, how we’ll manage the project, deciding what resources are required and by when and then procuring these resources. Planning our construction equipment needs, where we’ll place our cranes, sheds and offices. A project that’s not planned properly will cause problems later. Planning also means considering all alternatives to ensure we’ve chosen the most suitable construction methods and materials. But planning is also an ongoing process. I am frequently amazed how many project managers don’t appear to plan their projects on a daily and weekly basis. Work comes to a halt because construction materials or equipment haven’t been ordered or because we haven’t got the project ready for the follow-on activities. Some construction projects seem to drift from one crisis to another. Obvious problems seem to be overlooked until they hit like a run-away express train. Yes, some project managers are good at putting out these fires, but how much better would it have been to avoid the crisis in the first place? Set time aside each day to plan and consider what has to be done next on your construction project, then ensure that the processes, materials, people and equipment are in place so the work will be able to proceed as planned. A little extra time spent on planning will save you money and time later. planning your construction project 5. Not having a good construction schedule (programme) which is regularly updated and referenced. I’ve always found a project schedule an essential aid to managing a successful construction project. For smaller construction projects it can be a simple hand drawn bar chart and for more complex projects it could be a detailed resourced and linked activity schedule. The schedule helps plan and resource the project. But it’s also an essential part of preparing variation claims when the customer hasn’t provided information or access as required by the schedule. Of course, a construction schedule is almost useless if it isn’t communicated to the construction team so they understand what the next targets are on the project. 10 reasons why a construction schedule/program is useful "A project schedule an essential aid to managing a successful construction project." 6. Failing to read and understanding the contract document. Many contractors don’t read their contract until they’re in trouble. Well, by then it’s too late! The project contract spells out the project scope and the contractor’s obligations. It also spells out the customer’s obligations. By understanding the contract you can ensure that both you and your customer meet these obligations. Ignorance of the contract is no excuse. If necessary ask an expert for advice if you don’t understand a clause or you are unsure how to interpret something in the contract. The cost of this advice is often minor compared to the costs of interpreting the contract incorrectly. It often pays to have a summary of some of the more important clauses so they can readily be referred to. Don’t get into a project where the contract terms are so onerous you can’t meet them. your construction project contracts - why you need to understand them 7. Submitting a price which you know is below cost. Often contractors become so desperate for a construction project that they submit a price lower than their costs. Almost always this strategy is a disaster. Why pay the customer for the privileged of constructing their project. It saps the morale of employees who have to work on a project that is bound to lose money no matter how hard they work. These projects seldom turn out well. Don’t make a mistake when you price your next construction project 8. Failing to invoice for work done and not following-up to check that you’ve been paid. This seems obvious but I’m frequently amazed at how lax some contractors are at claiming for the work they’ve completed. Who works for free? If you’ve completed work submit your invoice in accordance with the contract. Just as important is to follow-up to ensure you’ve been paid. If you aren’t paid on time you probably won’t be able to pay your subcontractors and suppliers on time which will negatively impact your relationship with them and jeopardise progress on your project. Not being paid on time impacts cashflow and poor cashflow destroys companies. Negative cash flow – the death for many construction companies "More great tips to make you a better contractor." 9. Not doing your homework before submitting your price for the project. I’m astounded how many contractors price a project without doing their homework properly. Some contractors work for dubious customers who may not have the finances to pay for the work. Other contractors price projects without visiting the project site and then are surprised when the site conditions aren’t as expected – maybe the access is limited, the ground conditions are difficult to excavate or the terrain is steeply sloping resulting in additional costs. Project conditions and laws often vary between states and sometimes even between counties. Ensure you have allowed for these differing conditions in your project price, you don’t want to have an unpleasant surprise after starting work on the project. Don’t Submit Your Construction Price (estimate/tender) Proposal Until You Get These Questions Answered On A Site Visit 10. Wasting materials. I’m sure we are all familiar with the loads of rubbish produced on construction projects. This rubbish is generated from demolishing unacceptable work, over-ordering of materials, off-cuts, packaging, wrongly ordered materials, materials broken during handling and installation, and products that are no longer required. The cost of this waste isn’t only the original cost of the material but also the cost of disposing it which can be enormous these days. This waste can often be cut dramatically by reducing the amount of rework, better ordering procedures to ensure off-cuts are minimised, educating employees about the cost of waste and encouraging them to handle materials more carefully and by implementing better material handling and storage systems on the project. But the waste isn’t just about wasted materials it also involves improving productivity on the project and the better use of equipment. Let’s get smart and cut wastage. Ordering the correct quantity of construction materials "Let’s get smart and cut wastage." Ensure the success of your construction projectI’m sure you agree that most of the points above are obvious, yet it’s surprising how often they feature when projects go badly. By concentrating on eliminating these 10 deadly sins on your project you will have a more successful and profitable project. Of course there are other sins and I’m sure you can add to the list. We would like to hear your comments. #constructionmanagement #constructionprojects #construction #contractors This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2023 This article is not to be reproduced for commercial purposes without written permission from the author. "What is holding your construction project back?" Many construction projects are completed late. The reasons for this can be complex and depend on many factors. Often it’s the fault of the contractor and their poor project management. Late completion is costly to both the contractor and the customer. It also damages the contractor’s reputation. Planning the construction project properly before work starts and managing the project during construction is essential and goes a long way to avoiding delays. Equally important is to have a well-prepared construction schedule (construction programme) which considers the construction methodology and the known constraints. This schedule needs to be regularly updated and the results assessed to ensure the construction project is on-track to be completed on time. Mistakes that impact construction schedules/programmes. With this knowledge the project team can take timely action to rectify schedule slippage. If slippage isn’t corrected as soon as possible it invariably becomes worse, and the time remaining to catch-up the lost time becomes less, making it harder to make up the delay. It will eventually become impossible to catch up and finish on the due date. Unfortunately, many contractors don’t investigate why their construction project is falling behind and simply add more resources in an effort to catch-up. This is expensive and doesn’t always help. By the time they find out that more resources aren’t working, more time has slipped by and there’s less chance of catching up. "It’s often the case that the customer is causing delays which weren’t foreseen in the contract document. Why should the contractor then be responsible for these delays?" In a previous post I discussed some reasons why contractors cause themselves to fall behind schedule. (Read: 10 Reasons why your project is behind schedule.) Many of these reasons can be easily rectified. However, in some case it’s not the contractor’s fault, rather the customer or their team that’s causing delays to the construction. In some cases these delays should have been allowed for in the contract construction schedule as they were spelled out clearly in the contract document. However, it’s often the case that the customer is causing delays which weren’t foreseen in the contract document. Why should the contractor then be responsible for these delays? It’s important for the contractor to highlight these delays to the customer and the team so they can take steps to rectify the situation. Also, the contractor needs to submit an extension of time claim (delay claim) for these delays so that they aren’t penalised for finishing the construction project late when it’s not their fault. They also must recoup costs they have incurred due to the delays. 15 Rules for construction variation claims and change orders "There are many reasons to consider when analysing why the construction project is falling behind schedule." Is your customer, or their team, delaying your project?There are many reasons to consider when analysing why the construction project is falling behind schedule. We previously discussed reasons due to the contractor. Now let’s discuss the reasons customers delay the project: 1. The customer provides construction information late. I’m sure we’ve all been on projects where the client’s drawings have been issued late. This delays the project and frustrates the contractor’s team. If the customer has an agreed contract schedule they should know when the information is required so there’s no excuse. Providing an information schedule which links back to the construction schedule is a valuable aid. The customer often has to be regularly reminded of the forthcoming project information requirements. Immediately notify the customer (or their project manager) when information is late and where necessary lodge a delay or variation claim. An introduction to construction variation claims for construction project managers video 9 - What information and by when? 2. Late access. Often contractors are dependent on the customer providing access in accordance with the agreed construction schedule. The project will be delayed if these dates aren’t met and the contractor is entitled to claim for these delays. 3. Changes in specification. This is something that contractors don’t always detect until it’s too late. Change in specifications often increases the price of items, but they could also have longer manufacturing lead times. In some cases specifications are changed after items have been ordered which means that the original order has to be cancelled and new orders placed which can significantly delay projects. Sometimes customers and their designers aren’t aware of the implications to the project of these changes. If they are immediately made aware they may revert back to the original specifications to avoid delays and additional costs. 4. Scope increases. One mega project we were constructing was priced on a re-measurable bill of quantities. During construction our construction team was struggling to stay on schedule and was continually asking for more resources. Eventually we had much more equipment and people than we had allowed when we priced the project and consequently were showing major losses on our cost reports. When the team eventually caught up with re-measuring the quantities they found that some items had increased in quantity by more than 25%. Unbeknown to the construction team they had been accelerating the works at our cost – doing more work in the same period of time. Many projects increase in scope and contractors need to continually compare the actual scope with the scope they priced. Increased scope usually means we need more time to complete the project or additional resources to complete it in the original time. Contractors need to timeously notify their customer of scope increases as these usually add to the project cost which is detrimental to the customer’s budget as well as requiring additional time to complete. "Increased scope usually means we need more time to complete the project or additional resources to complete it in the original time." 5. The client’s activities cause delays. Sometimes the contract document includes customer activities and constraints that the contractor has to work around and accept. In these cases the contractor’s schedule should have taken account of them. However, often during the course of construction the customer introduces new constraints. On some projects we have had to shut down the work several times a week to allow our customer to carry out blasting activities. In other cases our work hours have been limited. Some existing facilities may have particularly rigorous security arrangements which impacts and delays the movement of people and materials onto the project. 6. Additional quality tests and inspections. Customer’s quality managers at times can introduce additional tests or quality inspections which are not only costly but can cause delays. Some clients add in additional ‘hold’ or inspection points or require 24 hour or even 48-hour notice periods for inspection. It’s important the customer is immediately notified so they can reassess these requirements to ensure the additional costs are worth the benefit. "Quality managers at times can introduce additional tests or quality inspections which are not only costly but can cause delays." 7. Late drawing or design approval. The project construction schedule and document should stipulate the maximum turn-around time to approve the contractor’s drawings and designs. Some customers aren’t good at keeping to these times. However, in some cases contractors cause further delays because their drawings aren’t correct, are not submitted through the correct channels or aren’t in the correct format. 8. The customer’s team doesn’t immediately respond to request for information and drawing queries. Unfortunately, I’m sure we’ve all received drawings with missing or conflicting information. On occasion querying and receiving the corrected information can be a tedious and time consuming process which delays the construction project. These delays need to be brought to the customer’s attention. We always include a list of all outstanding queries in our project meetings. 9. Customers’ not providing facilities and utilities in the required quantities and in the time they were obligated to supply them. On one of our earthmoving projects the customer undertook in the contract document to supply water at a specified point and in the quantities we required. Unfortunately the designated water point wasn’t ready until we were several months into the project. The alternative supply was 3 miles further away, it was used by other contractors and it couldn’t deliver the quantity of water we required every day. We not only needed more water tankers to haul the water a longer distance, but they had to queue behind other contractors to refill. As we know water is required for compaction so the limited water supply reduced the amount of material we could compact each day. This reduced our production which increased our costs and caused major delays. Ensure that the customer has provided the utilities and facilities where the contract says they should and that the quantities are in accordance with the agreed contract. 10. The customer’s other contractors impact and delay your work. They may restrict access to your work areas, damage your completed work or hold-up your work where you are required to interface with them. "Know when you can claim and what you can claim, then present the variation claim or change order with full information and backup documents." Ensuring your construction project is finished on timeBy being aware of the customer’s obligations in the contract document and the project construction schedule contractors can take active steps to ensure their customer fulfils them. Customers are quick to blame the contractor for delays to the project and fail to understand how their own actions are damaging progress. "Contractors often require to manage their clients and customers to ensure the construction project is completed on time." Don’t allow your customer to delay your construction project. Ensure you have an agreed project construction schedule which specifies information and access required dates. Regularly monitor construction progress and understand where and why delays are occurring and then take swift action to correct slippage. If it's your customers fault notify them and advise them of the consequences so they can rectify their problems. Contractors often require to manage their clients and customers to ensure the construction project is completed on time. An introduction to construction variation claims. Video 6 Reasons for extension of time claims To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author. "Construction company estimating departments are sometimes like sausage machines turning out price after price, quote after quote." Construction company estimating departments are sometimes like sausage machines turning out price after price, quote after quote, working on a number of project estimates at any one time. I’m amazed at how construction estimators manage to keep the different projects separate, how they isolate and review different supplier and subcontractor quotes for the different construction projects, how they manage to do this without making mistakes. Or do they? Where do estimators get their prices? Unfortunately, contractors do make mistakes pricing construction projects. These mistakes might increase their price, probably meaning they don’t win the project. Sometimes they fail to include documents requested by the client resulting in their proposal or quotation being disqualified or going in the trash (a waste of effort). Other times they under-price an activity and they lose money when they construct the project. Of course, companies can avoid some of these problems by being more selective with which construction projects they price, discarding projects which are unsuitable and concentrating on those that they really want. However, even so mistakes happen. Ask these questions before you price a construction project"Carry out a few checks and ask questions before submitting your price." Ask these questions It’s prudent to carry out a few checks before submitting your price. Ask yourself and your team these questions:

Price your construction projects correctlyUnfortunately, some contractors end up submitting their price without checking it properly. A poor submission may end up in the wastepaper basket. Worse a price that has errors may mean the contractor wins a project with a price that’s too low which results in them losing money on the project. Your tender submission or quotation – Get it right What mistakes have you made in your price submissions? This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2023 This article is not to be reproduced for commercial purposes without written permission from the author. "Unfortunately many construction projects are completed late." Unfortunately many construction projects are completed late. Invariably this negatively impacts the contractor’s reputation and costs both the contractor and their customer money. Often the contractor has to pay penalties for finishing the project late and they incur additional costs to remain longer on the construction project. The customer receives access to their facility late and usually faces additional costs for supervising the project for a longer period. #constructiondelays A well-prepared construction schedule which is regularly updated allows us to detect early when a construction project is running late. The Good, the Bad, and the Ugly of Construction Project Schedules. When we fall behind, the normal course of action is for the contractor to place more resources on the project or work extended hours in the hope of catching the lost time up. Unfortunately, this doesn’t always help as the true cause of the slippage hasn’t been uncovered. In fact adding more people or resources to the construction project may even add to congestion making the problem worse – especially if they aren’t the right resources. "When schedule slippage is detected it’s important to uncover the real reasons and then take action to rectify the problems." Usually, the longer the problem persists the worse the schedule slippage becomes, and the less time remains to catch-up the lost time on the construction project. When schedule slippage is detected it’s important to uncover the real reasons and then take action to rectify the problems. Sometimes the cause may be a minor bottleneck which could be fixed with small adjustments to the running of the project. Why construction projects are completed lateReasons for construction projects falling behind schedule There are many reasons for a construction project finishing late. In this article I’ll only focus on reasons caused by the contractor. These include: 1. Material handling on the project site – this is one of the commonest causes of delays on projects. Construction materials aren’t reaching the area where they’re required. This is a particular problem with multi-storey buildings where everything has to be lifted by crane. Projects often underestimate the number of cranes required, forgetting that trucks have to be off-loaded and that lifting activities don’t happen uniformly throughout the day. Congested project sites can also be a problem delaying construction material deliveries and blocking access routes. What can appear simple on a piece of paper, getting an item from point A to B, is sometimes not so simple on a busy construction project. Yet often simple steps such as packaging materials differently, having more materials handling equipment, working the lifting equipment longer shifts, changing the sequencing of lifting in the day or more focused supervision on this activity can unblock this bottleneck and improve production on the whole construction project. Handling construction materials "Project Managers often underestimate the number of cranes required," 2. Poor productivity. If our labour and equipment aren’t producing what is normally expected we will need extra resources to complete the same amount of work. However, just throwing additional resources at the construction project doesn’t always yield the desired result and it’s also very costly. It’s often more effective to uncover why the productivity is low and try and rectify the problem. Some reasons for poor productivity include:

3. Frequent breakdowns of construction equipment. Breakdowns of key items of equipment such as cranes, concrete mixing plant or excavators can cause severe disruption to a construction project. After suffering innumerable delays on my projects due to crane breakdowns I persuaded the company of the folly and the cost of using old cranes and we embarked on a replacement scheme. Sure, new mobile cranes are expensive, but just the increase in productivity on our construction projects more than compensated for these additional costs. Regretably, those studying project construction schedules don’t always appreciate how disruptive broken construction equipment can be. Even hiring a better replacement item can change the mood and productivity on the project. The Alarming Truth about Using Old Construction Equipment "Breakdowns of key items of equipment can cause severe disruption to a project." 4. Shortage of construction materials. This is usually caused by the team not ordering sufficient materials or not allowing for fabrication lead times. Sometimes however the supplier has their own problems, and it may be easily resolved by approaching another manufacturer. Even problems with insufficient delivery trucks can disrupt supplies. It could be an easy fix by bringing on other transport companies. Do Your Material Deliveries Suck? How to avoid problems 5. Theft of construction materials or equipment. In previous articles I highlighted one project where a third of every load of cement the project received was stolen en route. The project experienced cement shortages which hampered our production and caused delays. Sometimes the theft could be as small as removing a battery from an excavator which, in the countryside, could mean the machine and the other equipment working with it stands for several days. Even the theft of small electrical tools from a tradesman can mean they’re not working efficiently for hours or even days. (A wave of tool theft spurs hi-tech security systems) Unfortunately theft can create bigger problems particularly if it is a long lead item such as an electrical distribution board. Corruption, Fraud and Theft in Construction 6. Having too few resources of a particular trade. I’ve often experienced construction projects where one trade has held up the others. For instance, if you have insufficient scaffolders you aren’t going to be erecting the scaffolding fast enough for your steel fixers and carpenters, so they are going to be standing. If you need more people, ensure you get those with the construction skills that are insufficient on the project and not just more of everyone. Sometimes there is only a minor hold-up and it may be possible to get the construction project through by asking a few employees with the required skills to work extended shifts. "Rectification work takes valuable resources away from critical tasks." 7. Poor quality work resulting in rework. Poor workmanship causes delays when completed work has to be demolished and rebuilt. Even minor rectification work can take valuable resources away from critical tasks. Who is responsible for quality on your construction project? 8. The Supervisors and the team doing the work aren’t aware or don’t understand the construction schedule. This may seem stupid, yet, this happens surprisingly often. Management may give a copy of the updated construction schedule to Supervisors but often this is the schedule for the whole project for the remaining duration and it could be several or even hundreds of pages long. Most Supervisors are only concerned with their section of work and what needs to be done in the next couple of weeks. Therefore, give them only their relevant sections of the construction schedule for the next few weeks. In fact, I’ve found that, if possible, providing a construction schedule in a pictorial form highlighting the important dates works well, as it can be put up on their office wall and is easily understood by their team. Even better is to spend time explaining to the Supervisor what needs to be achieved and explaining why certain dates are critical to the construction project. It’s amazing how a team who know what they have to achieve and the reasons behind it can then deliver. Does Your Team Know What's expected From Them 9. Neighbouring sections of construction work negatively impact each other. This is usually because of congestion, safety issues or access problems. By analysing these problems sometimes we can develop solutions which may mean using different access systems, bigger cranes, additional safety measures, changing the sequence of the work, or even working different shifts (one section could work day-shift while the other at night). Yes, there may be additional costs, but not falling behind schedule is often more important. 10. A subcontractor isn’t performing. One non-performing subcontractor can impact other subcontractors and your own team. Often all it takes is the subcontractor to improve their performance, bring on extra people to stop slippage on the schedule. In extreme cases you may consider taking work away from the subcontractor. Of course ensure that your dealings with the subcontractor are in accordance with your contract with them. Also, understand why they aren’t performing as the reasons could be due to your team or the customer’s team. Managing subcontractors on your construction project. What you should consider. Find what is delaying your construction project and fix the issueWe will all at some stage fall behind schedule on our construction projects. It’s important we detect this slippage early. Then, don’t take the obvious choice and add more people to the construction project, but rather analyse the reasons for the slippage and then take the necessary action to rectify these issues. Spend some time in the field and watch what the construction teams are doing. Where are the bottlenecks? How could we do things better? Make sure your team understands the key dates on their section of work and how it impacts the project as a whole. Of course, construction projects aren’t only finished late because of the contractor’s failings, it’s often caused by the customer or their team. My next article will deal with how customers can cause projects to finish late. Is your client delaying your construction project? It’s important to consider and address all the causes for a project running late so you can ensure slippage is caught up and the project is completed on time. #constructiondelays #constructionmanagement #constructionprojects To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2022 This article is not to be reproduced for commercial purposes without written permission from the author. |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed