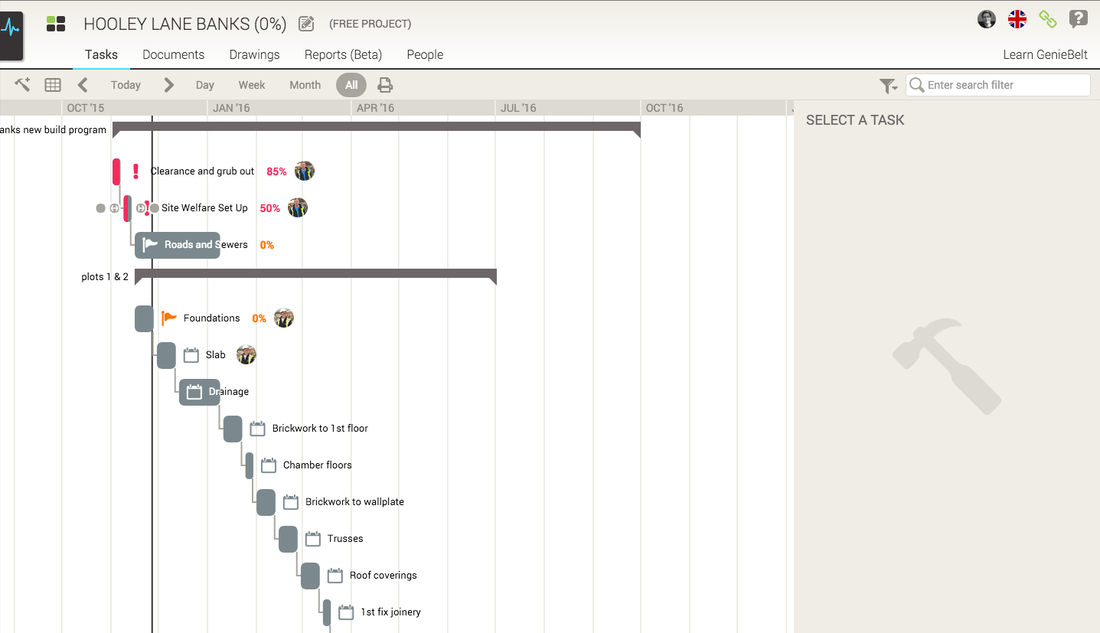

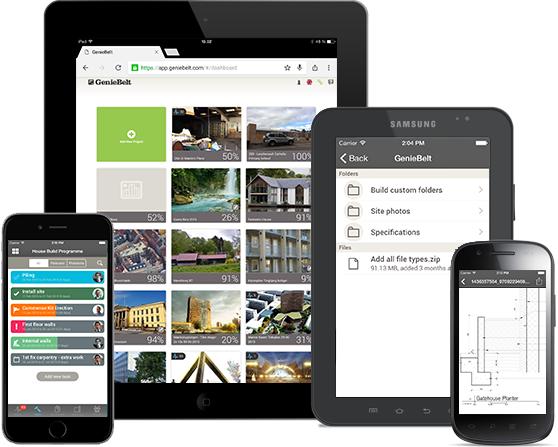

(Guest post from Stuart Howie Senior Advisor to GenieBelt) Way back in the mists of time - well, 1988, actually - I got a job as Site Agent with a housing developer up in Cumbria. It was taking the usual 12 weeks from the contracts being signed to the new, very proud, owners moving into their new homes. The foundations and infrastructure, of course, were already in place for each house before the sales people attracted buyers. With the benefit of hindsight it was a rather boring job with not much to do except keep an eye on the skilled trades and make sure their workmanship was always at an acceptable level. Now, these skilled tradesmen were all on price work. As I chatted with them, they had a common complaint; they couldn’t get in to get work done because they couldn’t get access because someone else was in their way, their materials weren’t on site, or they couldn’t get on our site when we wanted them because they were working elsewhere. I was wandering around the local Library looking for novels I fancied reading when I came across a non-fiction book on Planning. I think I must have found it a bit boring at the time because I can’t remember anything about it. However, it must have put the idea in my head. What happened next was that, on site, I started scribbling ideas on bits of paper to get the hang of this Planning mystery. After that I wandered around asking all the trades how long, or rather, how short a time it would take them to do their bit in each house under ideal conditions. Then the next question was: how to make a decent Programme everyone could look at? Remember, no computers, no plotters back in the day! The biggest pieces of paper I could find were superseded drawings. One went up on the office wall and I wrote all the major Tasks, by hand, on a pretty poor-looking GANNT Chart! This ended up as several Programmes on the wall because there was a new one for each house as a buyer was found. The lads loved me for this! Suddenly start-to-handover was reduced to 6 weeks! The lads were coining it in and could afford foreign holidays for their families! Remember they weren’t a common luxury back in the 1980’s! The only down-side, from my point of view, was that my site walkabouts had to be quicker and more thorough in order to keep pace and make sure my newly-introduced policy of “de-snag as you go” was stuck to! Life moved on and I somehow found myself in commercial construction. It was about the year 2000 when I was Site Manager for an office fit-out in Bristol that I got chance to do more planning of a far more serious nature. It was a very tight time-scale we had to work to and everyone was worried about handing over on time. I became quite infamous on this job, actually! Directors would come on site and say “Look! A site manager - and he’s using a laptop computer!”. Among the software on it was MS Project. I chatted to the subbies’ ganger-men to ask how long each Task would take them; what materials they needed and all the other stuff to be able to make up a Detailed Programme to Completion (DPC). “That was my first experience of planning in a more detailed manner. You have my personal assurance that MSP and PC’s are better for it than paper from old drawings, and that we did finish on time!” The next bit of my education in this planning game was up in the North East on a new prison when I was given the free-lance contract job as a “Planner” for one of the subbies. The sad bit was this was back to hand-drawn DPC’s on superseded drawings! These were better than their predecessors because I could at least copy them from my laptop MSP version. I couldn’t draw them that detailed, of course. However, the main contractor, MACE, had a professional Planner on site. He had a plotter for his programmes! - along with the only other computer on site! Anyway, he gave me lessons and got me really interested. After that I decided to get really clued up on this planning game! These days I have quite an extensive collection of books on the subject. To come up with a good DPC isn’t a quick and easy thing to do. What it requires is that someone has to look at a 2-dimensional (2D) drawing and begin to build it in their head. That requires a quite extensive experience of construction in order to be able to identify quite how that project will be best undertaken. When this is done the Planner has a 3-dimensional (3D) mental model of the project. The next, and final, stage is to get all the Tasks, in the order in which they need to be completed, entered in their planning software. The remaining factor to be considered is how long each of these Tasks will take. A guess based on experience may be sufficient for many of them, but a discussion with the sub-contractors about their views is often advantageous (this by the way was me doing Lean Construction back in the 80s). The other thing that is advisable is to check up on procurement periods for materials. Some may be very long and need entering as a Task for it to be ordered before the start on site. Once all this is done and it is entered on the programming software, with all dependencies indicated, then the Planner has produced a 4-dimensional (4D) model of the project. This will show, and this is particularly important, the Critical Path. These are the Tasks which have to follow each other closely or the whole project will be delayed. Once that is done it is over to the Quantity Surveyors to insert costs and work out their cash flow. In all this, the two main restraints are the start-on-site date and the hand-over date, both of which are contractually obligated. Everything has to happen between those two dates. Similarly restrictive dates can be contractually imposed on sub-contractors. “Successful” construction projects are defined as ones which finish on time, to standards and to budget. They often have the beneficial result of leaving behind “delighted clients” and these are defined as ones who automatically return to you when they have another contract. I had this confirmed to me by a Vice President of Insignia Properties, the second-largest commercial property developer in the U.S.A.. He said he only used four contractors he knew he could rely on! (Side Note, Paul wrote an excellent guest post for GenieBelt titled: The Ultimate Guide To Becoming a Successful Contractor (Well worth a read!) Now we have our DPC and we have a plotter on site. Previously I would have printed off a few cpies of the DPC on the largest size paper the plotter can handle and stuck them up around site. But just like when I moved from drawing my Gantt to using MS Project, now I would import my MS Project programme into GenieBelt. Individual tradesmen like this because it tells them what they should be doing and when and this information is accessible from their phone in their pocket. It also seems to motivate them to work faster than the DPC actually states!  What the site-based planner, site manager or project manager then has to do is, at least once a week, walk around the site and mark up progress for every single Task through a simple swipe of his fingers and all is updated immediately – which saves me time since otherwise I would be marking up progress, importing those paper notes into MS Project and then printing the new DPC. What this up-dating does is allow any slippage to be noted and those Tasks accelerated. If disaster strikes and, for some reason over which there is no control, a Critical Path Task is behind programme, then there has to be a major re-think and the order in which Tasks are completed need to be revised. Because there is a detailed record of who has to do what and by when, and as any over-run for any Task is high-lighted by the software, the finger of blame can easily be pointed if there is any Delay in Completion and hand-over. This fact alone tends to keep all the parties involved committed and compliant. The consequences of Delay are Liquidated and Ascertained Damages (LAD) and they can be horrendous! In my experience £600,000 per month or part thereof is fairly common. To make that worse, to be a week late in Completion might require the Client, under their contract with their existing landlords, to extend their leases on existing rental premises by 3 months! Their only alternative would be to send all their staff on holiday for that week and to stop trading! We’ve now established that a DPC is not a quick and easy thing to do. In consequence expert and experienced Planners are the highest paid personnel in U.K. Construction. However, nobody should be put off compiling their own if there isn’t a Planner available to do it! The more detailed a DPC is, the better it is. However, as I learnt in my early days, even a poor version can make all the difference! If you are a Site or Project Manager and you aren’t supplied with a DPC I urge you to have a go at it and produce your own! We even made GenieBelt free for you to create a DPC! So that is a lot about DPC’s covered; now is the time to get back to the topic :- Why a Detailed Programme to Completion Ensures Project Success. It is my belief that this is the single most important document on any construction project and the reason for that are these! : -

There it is! With a DPC the construction project will be a successful one which finishes on time, to standard and to budget! It may also bring repeat contracts from the same “delighted client”! The reality is that for a commercial construction contract of, say, £5 million, the cost of compiling that DPC by a Planner will be about £20,000. To try to do that construction project without a Detailed Programme to Completion can well end up in actions for LAD and bankruptcy! That makes the investment look a pretty sound one, doesn’t it? Blog written by Stuart Howie Senior Advisor to GenieBelt Stuart has built something like 2,500 houses, refurbished 1,500 homes and been involved in 150 commercial construction contracts on which he spent about £5 billion, and of which a 100 were project turnaround roles! Connect with me on Linkedin To read more on schedules or programmes read: Mistakes that impact construction schedules (programmes) For other useful construction management articles go to the index of construction articles on this website.

0 Comments

Reducing fraud and theft on construction projects

The types of theft in construction"Theft and fraud take many guises in construction. It is often difficult to control as we depend on many people, subcontractors and suppliers." Theft and fraud take many guises in construction. It is often difficult to control as we depend on many people, subcontractors and suppliers. Project sites are often spread out and unsecured. Some forms of theft on construction include:

The cost of theft on construction projectsWhen we have theft we often only consider the direct cost of replacing the item. But the cost is often more than this. The cost may include:

"You need to be ever vigilant and ensure that there are checks in place that will detect when fraud or theft have occurred. " Preventing fraud and theft on construction projectsWhat you can do You need to be ever vigilant and ensure that there are checks in place that will detect when fraud or theft have occurred. Not only will this be a deterrent to potential fraudsters and thieves but it will enable steps to be implemented to prevent more theft. Doing simple material reconciliations on projects is a simple way of detecting stock losses, but it is also useful as a double check that all work and materials have been invoiced to the client. It also serves to detect excessive wastage. We have to place some people in trusted positions but it is important to realise that people’s circumstances change and we cannot know what financial stresses they may be experiencing in their lives, or what temptations they are unable to resist. It’s therefore important to ensure that where necessary there are 2 stage checks in place. In addition by knowing your employees and regularly talking to them you may be able to see the warning signs of potential problems. Staff need to be vigilant and understand how important it is to have checks in place and ensure that these checks and controls are diligently carried out. On project sites where theft is a possibility extra security measures may have to be installed such as cameras, fencing and security guards. High value and high risk items may need to be secured when not in use. Like this article – please comment, like and share it. Questions What is the worst theft or fraud you have uncovered on your project? What was the cost? How did you discover the theft? Is theft generally a problem on your projects? #constructionmanagement #contractors #constructioncontrols "Very useful guide regarding the management of the construction projects. Open, direct and insightful." (Reader 3 - Amazon.co.uk) To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' Order your books from Amazon now 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you © 2015 This article is not to be reproduced for commercial purposes without written permission from the author. Construction schedules or programmes look great on paper or the computer screen, yet can hide errors that can make them worthless – even dangerous. They are an essential tool to getting the project completed on time. Personally I wouldn’t undertake a project without a construction schedule – even if it’s a simple hand drawn schedule. 10 reasons why a construction schedule/program is useful Unfortunately many schedules aren’t workable because some basic principles were forgotten. I have had clients want me to build the 2nd floor before the first – which as you can imagine in most cases isn’t feasible. Then there are facilities that are completed but can’t be operated because someone forgot to connect the utilities or services. We have probably all worked on projects in the rainy season, yet the schedule still expected us to be excavating and concreting foundations every day. Many schedules fail to take into account manufacturing lead times and some clients seem to think that contractors can receive a drawing and should be pouring concrete the next day – resources and materials are conveniently waiting on a shelf – immediately available and waiting to be called upon. #constructionschedule #constructionprogram #constructiondelays Construction schedule errors"The one thing that’s worse than not having a construction schedule is having a schedule that is incorrect." The one thing that’s worse than not having a construction schedule is having a schedule that is incorrect. Yet, many schedules aren’t correct. Here are a few common mistakes.

#constructionmanagement #constructionprojectmanagement #contractors What mistakes have you encountered on schedules? Were you able to overcome these problems? "Easy Reading. I have been looking for a book like this." (Reader 2 - Amazon.co.uk) To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you visit Construction Services © 2015 This article is not to be reproduced for commercial purposes without written permission from the author.  Image courtesy of Exsodus at FreeDigitalPhotos.net Image courtesy of Exsodus at FreeDigitalPhotos.net Despite advancements in technology construction projects often end poorly. I see different new project management software almost daily. Some of the systems on the market have potential to provide efficiencies and savings. These systems are often hailed as saviours for your next project. Companies often spend enormous amounts of money on implementing new systems and purchasing new equipment. Clients sometimes see these systems as the answer to delivering their project perfectly. Yet, despite using these systems many projects end up in failure. When I started construction the fax was the latest technology. Drawings were still produced on drawing boards. We priced our tenders manually, handwriting all calculations. We were just starting to produce construction schedules/programmes on the computer. Since then we have seen massive advancements and computers have taken over the design and drawing office and have become a way of life on construction sites. We receive instant communication, 24 hours of every day. But is construction more efficient? Are projects completed quicker? Are there fewer problems on our projects than 20 years ago? Is the extra cost companies incur really worth it? Undoubtedly we are seeing new design solutions that are innovative, often pleasing to the eye and with more efficient use of materials than in the past. However, we still see design and drawing errors, problems with design constructability and clashes of structures, and services. Construction projects are priced using innovative tendering software, often have schedules with thousands of linked tasks and are micromanaged by systems that log all communications, control drawings and record everything from safety statistics, costings, productivities and quality. Yet, we continue to see projects finished late, with poor quality and over budget or at a loss for the contractor. Technology is finally moving onto the construction site and there’s equipment that can routinely produce precise setting out, automatically control machines, we have new innovative light weight and easy to install materials, and numerous tools and equipment to make projects easier. But we continue to see work being redone, poor productivity, projects losing money and projects being completed late. In fact in some areas our problems almost appear to be worse. Why? In all of this, no matter how good the equipment, systems or computers are we still need to rely on people. In fact, the problem is sometimes exacerbated, because people now often rely purely on their computers and project systems, trusting what their computer is telling them. Where is the problem? Is the fallibility of this new technology the fault of the technology developers? The skills of the operator I’m sure many of us have worked on projects that at face value had a wonderful schedule/programme with hundreds and even thousands of tasks linked together and often resourced. Yet, the schedule didn’t work. The logic was incorrect. Yes the schedule said we could do the tasks in that time and order – but, who decided the logic and sequencing? Unfortunately the operator, who in many instances understands the programming software, but doesn’t understand construction. Many project managers don’t understand the scheduling software and leave the preparation of the construction schedule entirely to a planner/scheduler. All systems need to be programmed and operated by skilled staff. Unfortunately we often don’t train people properly, or rely on individuals who don’t have the knowledge or expertise. Garbage in garbage out Almost every project management tool and software system depends on the information entered. If this information is wrong the answer will be wrong. Incorrectly update your schedule and you aren’t going to know whether you are on program or not. Leave out some of your costs or incorrectly enter your revenue and your cost report is going to be meaningless – yet that same cost report will be treated as undeniable evidence that the project is making or losing money. A quality checklist completed on a device doesn’t mean the quality is correct. The individual completing the checklist should have the necessary knowledge and experience and the diligence to physically check that the work complies with the drawings, specifications and quality requirements. Interpret the information correctly We receive that updated program every week, have a quick look and if it looks ok it gets filed. Our percentage complete aligns with our targets but have we looked at our progress on the critical path? Have we reviewed items that have slipped and analysed the reasons and the possible future knock-on effects? We may have data showing we are completing the required number of punch-list or snag items every day, but if we aren’t analysing where these items are and which subcontractor is attending to their snag items we may find that certain subcontractors or areas are falling irretrievably behind. Most data is open to misinterpretation, can be used incorrectly or explained away with the wrong reasons.  Image courtesy of pakorn at FreeDigitalPhotos.net Image courtesy of pakorn at FreeDigitalPhotos.net Use the information wisely I’m sure we have all at some stage received information or an answer that was obviously incorrect. Yet some people blindly follow what they have been told even though common sense should tell them to stop and check. Then there are systems that tell us there is a problem – the project’s losing money, we are behind schedule, but then project managers take the incorrect corrective actions – sometimes even making the problems worse. We seem to generate endless strings of data on projects that we add to our monthly reports. Accidents, incidents, progress, invoices, claims, defects, audits, etc, etc. How much of this data is relevant, how much is analysed, how much is used? Yes, much of the data can be very useful, yet it is often ignored despite it taking valuable time to accumulate and document. Understand the fallibility of the system Many systems are fallible – I’m sure we have all heard stories of drivers blindly following their vehicle navigation systems into a lake or ocean. One needs to understand that roads change and update the system to take account of these changes. So too on a construction site things change and plans have to be adapted. But it is more than this, understand where errors can occur - which may be operator, system or input errors. By being alert to potential problems we are less likely to take the results at face value and should be able to put in extra checks and balances. The art of denial Of course there are some who will ignore what they are being told and carry on as normal regardless. How many times have you heard people say ‘we can’t be losing money’, ‘we aren’t behind schedule’, ‘I’m sure the GPS is wrong and we should turn here’. Well just because we don’t like or believe the answer doesn’t mean we should disregard what we don’t like. Sure take a closer look at the information and system but don’t disregard the answer just because you don’t like it. Are they telling the full story? There is a danger that we aren’t seeing the whole picture. Sure you might have a low accident rate but is your project safe – could there be a major accident around the corner? Drawings may be issued on time but are they correct and free of ‘hold points’? Use the appropriate technology or system Many systems aren’t designed for the construction industry. They either aren’t robust enough to be used in the field, include information or answers that have little relevance to construction companies, are difficult to operate with the skills levels in construction or can’t readily adapt to changing project conditions. Where possible use technology that has been specially developed and tested for the construction industry and technology that is supported by people who understand construction, and know what you need to achieve. What are we trying to achieve? Some construction companies jump in with new systems and software because they are the ‘flavour of the moment’, the ‘new buzz word’, they are conned by good sales talk, they feel they have to ‘move with the times’, or they are just desperate for a solution. Yet many companies haven’t thought through what they are trying to achieve, what they need to achieve and whether the system is appropriate. Do they need the information the system will spill out? Do they have people with the time and skills to operate the system? What other systems in the company will have to be changed and adapted to fit with the new one? Is the system build for the construction environment? Buy-in Sometimes management introduce new systems and equipment into the organisation without explaining the purpose and benefits of the system. Unfortunately many people are reluctant to change and some won’t use something they aren’t familiar with so we end up with useful systems and equipment being ignored, used in a half- hearted manner or being used incorrectly. Any new system needs employee and management buy-in to make it successful. The best tools can’t make a poor project manager good A carpenter can have the best woodworking tools, but if they don’t have the necessary skills they will still be a poor carpenter. Project managers are the same – the best tools and equipment won’t turn a poor project manager into a good one. Yet, many construction companies place extraordinary reliance on equipment and construction management software hoping that the project manager staring at data on a computer screen will suddenly have a ‘light-bulb moment’ and steer their project on the course to success. It’s simply not going to happen. In fact it’s less likely to happen because sitting behind a computer screen in my experience is not the way to manage a project. What we need is technology that will provide managers with more time to be on the project site. Conclusion

Construction is slow to embrace technology. Talk to any provider and they’ll tell you the disinterest most contractors display to innovation. However, the right technology used correctly can be hugely beneficial to the construction industry, providing greater accuracy, more complex processes and more efficient use of resources. But technology cannot be relied on to replace common sense and project management skills – at least not yet. To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below: 'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Purchase your book from Amazon dot com Purchase your book from Amazon UK © 2015 This article is not to be reproduced for commercial purposes without written permission from the author. On construction projects daily records, or reports, are important, yet Project Managers often leave them for other staff to prepare and submit. These reports may be referred to in the event of a contractual dispute, therefore they must be accurate and, if possible, signed by the client or their representative. Often it’s a project requirement to submit these reports daily, and even if it isn’t I would recommend every contractor still submits one. #constructionprojectmanagement #constructionreporting What to include in construction project daily reports The daily report should record:

The numbers of people recorded on site, in the diary, may be important when the client is adjudicating any claim for acceleration or delays. It’s important when work is performed on a cost recovery basis that the number of personnel recorded in the daily report ties-up with the cost recovery records. If they don’t agree, the client may only reimburse the contractor for the lesser number. Often a contractor experiences a delay, and records it on the daily report, but when the delay continues, they neglect to record its continuation, which can cause a problem later, because the delay has been recorded as if it only affected one day. It’s important to note every delay on every day that it affects progress. Has Your Project Been Delayed? #constructionmanagement #constructionreports #constructiondelays Accurate construction reports are essentialDaily reports can form a vital part of delay and variation claims. Yet, they are often poorly done and neglected by Project Managers who often delegate the task of completing the report to juniors who don’t understand why care needs to be taken when filling in the report. Will your next construction variation claim be successful? This article first appeared in www.qsadvisor.com

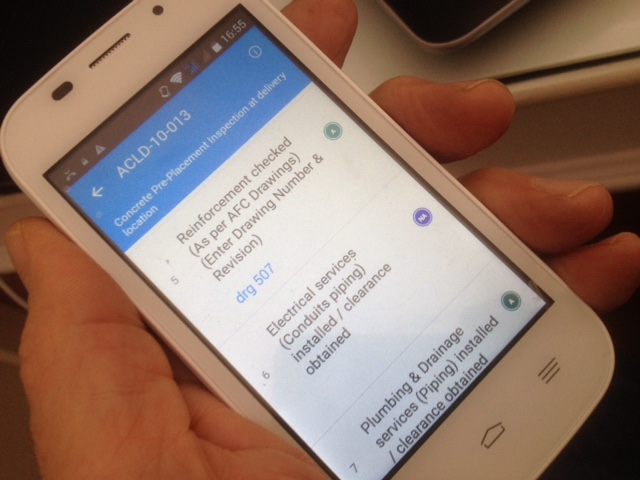

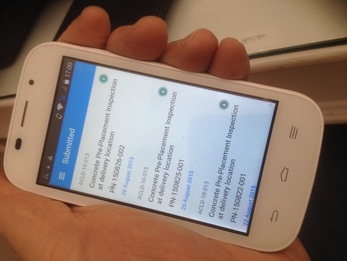

(Written by Paul Netscher the author of the acclaimed books ‘Successful Construction Project Management: The Practical Guide’ and ‘Building a Successful Construction Company: The Practical Guide’. Both books are available in paperback and e-book from Amazon, Amazon UK and other retail outlets. This article is adapted from information included in these books. To contact the writer go to contact) 2015 This article is not to be reproduced for commercial purposes without written permission from the author  Quality paperwork is regarded as a chore or waste of time by some contractors. Yet, quality paperwork is an essential component to managing quality on construction projects and ensuring there is an auditable trail. Losing a checklist can be expensive and cost time if the work has to be rechecked. Any way we can simplify our quality checking process should be welcomed. In the past Working on construction projects in the past we always did our quality checklists on a piece of paper. At the start of the project we prepared various checklists in accordance with our quality plan and document. Whenever we were required to carry out a quality check, whether it was a pre-concrete inspection, post-concrete inspection, pre-render or plastering inspection, we got a blank copy of the checklist from the office, stuck it onto a clipboard and went to work on site ticking off the relevant items. Usually, once we were satisfied the section conformed we signed the checklist and then had to search for the client’s engineer or QA inspector to authorise the completed checklist. Only then could we proceed with the work in hand, whether it was pouring concrete or placing the next layer of dirt. Being distracted we usually forgot the checklist on the clipboard adding another checklist to the board when we did our next inspection. So it went on until the clipboard couldn’t hold any more completed checklists. Invariably by this time the 1st checklists were stained from sweat, dust, oil, coffee and rain and dog-eared.  When we got time we filed the checklists into the QA file. But of course there were some engineers who just dumped the completed checklists in a desk drawer where they lay until the project’s end. The end of the project arrived and the work was handed over, but final handover was delayed because the QA data pack or file wasn’t ready. Engineers worked long hours sorting out the checklists and filing them in the correct sections. Often there were missing checklists and some engineers even falsified checklists to fill in for the missing ones. Finally the data pack was complete and then it was copied so that the client could have their required pack (sometimes they even wanted a 2nd copy). Now Well time has moved on since those days, yet many contractors still use the paper system which astounds me. Not only is this slow and cumbersome but the contractor is exposed to risk should an inspection sheet be lost and the client insist the work is uncovered and inspected or redone. Our new generation of engineers have been brought up using smart phones and its second nature to reach for their phone. I was therefore surprised when I was approached by a company who have developed an app for Android and iOS to do quality inspections on a smart phone. It just seemed so obvious! Why weren’t construction companies using the system already? You download the app onto your phone. It comes with a complete suite of checklists (over 150). You can add your own checklists or modify those already supplied. Once downloaded, you can retrieve the required checklist anywhere on the project on your smart phone and don’t require connectivity. No running back to the office to find a blank checklist. No walking around the project with paper copies. Simply run through your checklist as you would normally do, ticking off the items that conformed, indicating items not applicable if they aren’t needed and marking items which don’t conform and adding comments – all on your phone or tablet. Furthermore, you can add photographs to the checklist to show the non-conformances or to prove that the check was in fact carried out. It’s that simple. If you need another party to authorise the checklist the app has a function to send them an email when you have connectivity. They can remotely authorise the checklist or carry out their own inspection, notifying you by email when the checklist is authorised. The completed checklist in pdf format is then filed in the correct folder. No more lost checklists! At the end of the project the checklists are easily retrievable and can be copied electronically or printed. But there is more. Each checklist is allocated its own unique number. At the touch of a button you can see how many checklists have been completed, how many haven’t been authorised, and you can track the common items which resulted in checklists not being passed. Conclusion So ditch the paper, move onto paperless checklists that will save you time and money, making your quality processes simpler and faster. However, there is more to this app. It can also be used for conducting your safety inspections. So whether it’s doing scaffold, equipment or excavation inspections, get out your smart phone, pull up the required check list and start checking. It’s all there in your pocket at the touch of a few buttons. Hey if someone as old as me (yes born BC - before computers) can be excited by an app then you have to know it’s a really simple system. Why didn’t I think of it! To clarify, I don't work for these guys and haven't been paid to write this blog, but I thought I would pass on information which might be useful. To read more visit http://www.asansystems.com Have you used a similar system? How does your company do their checklists? To read more about the author visit Paul Netscher on this website. To learn more about the author's books visit 'Successful Construction Project Management: The Practical Guide' and 'Building a Successful Construction Company: The Practical Guide' on this website. Want to ask Paul a question go to Contact. See how we can help you go to our Construction Services page. Will your construction project be 100% complete when it's finished? Well that appears to be a stupid question? If a project’s complete, that means it’s finished? Yet many contractors finish a construction project – hand it to the owner, but then spend months, maybe even years, completing snags and defects. They tell everyone the project is finished, but it’s not. Case study: Many years ago, while on business, I stayed at a hotel which had just been constructed for a major hotel chain. I was surprised to see so many construction workers still working in and around the hotel. Later that night as I showered I was dismayed that water from the shower ran across the whole bathroom floor, soaking everything in its path. I tried to form a dam with the towels and bath mat to keep the water in the shower, but without much success. Over the course of the next 18 months I stayed at the hotel on many occasions while visiting my own construction project, which we completed in this time. I stayed in many different rooms and most had a similar problem with the shower, together with other snags or punch list items. Over time the number of workers from the original contractor diminished, but there were still some repairing defects when I last stayed there. The construction period for the hotel had been less than 18 months, but here they were still repairing defects 18 months after the hotel had been opened! Imagine what that cost? But now in the city where I live this almost seems to be the norm. We own an apartment in a large building, and it took 4 years for the builder to repair leaks on balconies, and 6 years after it was completed the owners are still battling with the builder to resolve the leaking swimming pool. A similar story is repeated in many other apartment blocks. #constructiondefects #constructionquality #constructionproblems Why are there construction quality problems?"Poor quality construction quality is often due to all parties involved. Client, designer, and contractor." So where does it go wrong in construction? The owner Owners don’t help quality problem when they:

The designer Designers exacerbate the problem by:

The contractor Ultimately the quality of construction rests with the contractor. But contractors are often their own worst enemy. Contractors:

"The person who allowed the problem to occur in the first place doesn’t have to fix it, so is oblivious to the cost their carelessness has caused." But it’s also more than this. Contractors leave their snagging, or punch listing, to the end of the project, often asking staff to rectify mistakes made by others before them. For the duration of the construction works every one appears blind to the quality problems, accepting that if there’s a piece of paper ticked to say the item’s been inspected it must be ok. So the problem that occurs in apartment 1 probably is replicated through all the apartments to apartment 1091! Furthermore the person who allowed the problem to occur in the first place doesn’t have to fix it, so is oblivious to the cost their carelessness has caused. Repairing defective work on your construction project "Do you know what poor quality costs your project and company?" The cost of poor quality constructionOwners Owners think that poor quality doesn’t cost them anything – after all, the contractor will rectify the problem. But it does cost the owner.

The Contractor The contractor often does not even begin to understand the costs which are usually far more than just monetary.

"The action of all parties can negatively impact quality." Improving quality in constructionThe action of all parties can negatively impact construction quality. It’s in all the parties’ interests that they understand the actual costs of poor construction quality. Snag, or punch list items should be attended to as the construction project proceeds, preferably by the person responsible for the defect. These items should be tracked so they aren’t repeated. They need to be closed out as soon as possible so the construction project is completed and staff can move off site. How important is quality on your project #constructionmanagement #constructionprojectmanagement #contractors "Brief, easy to follow, good examples and the real management world. I will use it has a reference on my job." (Reader Amazon Spain) The information is this article is adapted from the author's acclaimed books ‘Successful Construction Project Management: The Practical Guide’ and ‘Building a Successful Construction Company: The Practical Guide’. Both books are available in paperback and e-book from Amazon and other retail outlets. Read Reviews. Read more about Paul Netscher Want to contact Paul send a message Contact See how Paul Netscher can help you on the services page.

This article was first published in www.accedeglobal.com © 2022 This article is not to be reproduced for commercial purposes without written permission from the author. |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed