|

Isn’t it annoying when you’re working on a construction project and you run out of materials before the task is completed? You’re sure you ordered enough material to complete the work! Why isn’t there enough material? Did someone steal it? Well perhaps they did – but there could be several reasons why there’re insufficient materials for the task. Sometimes the construction materials needed can be quickly gotten from the nearby store, but even so work is interrupted, possibly the construction team stands idle while the material is fetched, or the workers must be reorganised to do other construction work in the meantime. Unfortunately, in some cases the material isn’t readily available, and it could take several days to get the missing items to the project. Inevitably there are additional costs and delays which could jeopardise the success of the construction project. Why do projects experience construction material shortages?There are many reasons for construction material shortages and proper care should help avoid this from occurring.

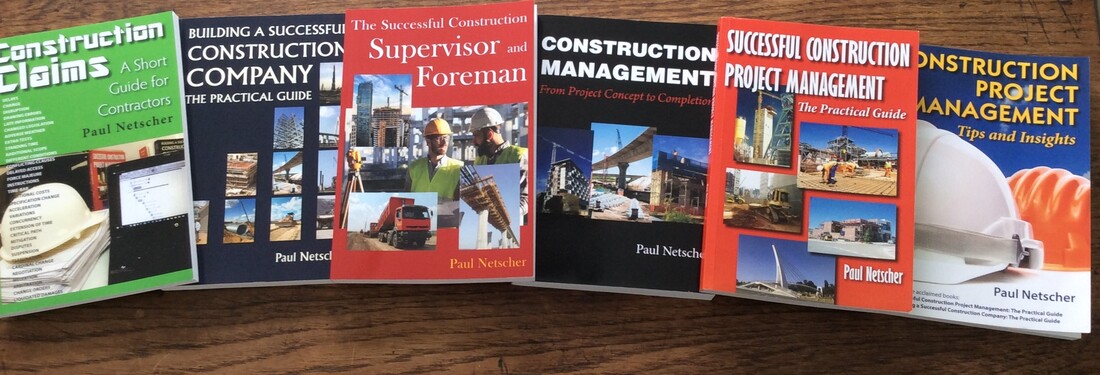

Have the right quantity of materials on your construction projectIt’s worth spending extra time to ensure you order the correct quantities of construction materials. Where necessary ask for expert advice to determine the normal wastage factors of a particular product. Look at different options for cutting and installing the materials, as well as the various sizes the products are available in. Careful planning and ordering of construction materials can reduce costs. Of course, always ensure that those installing the products understand how they should be installed to minimise waste and so that they don’t undo your careful planning. This could avoid costly and embarrassing mistakes. Investigate shortages before ordering additional construction material. The missing items may be lying unnoticed somewhere on the project, or the supplier might not have delivered the material yet. Regrettably sometimes construction project managers order additional materials to make good shortfalls, only to discover that the missing materials were found or were delivered later – resulting in there being too much material. Of course, always check the construction drawings because a shortfall of material may be because of drawing errors which resulted in more material being used than was allowed for. Importantly, keep a constant check on the available construction materials and act when it appears that there may be insufficient materials. Take timely action to ensure that your construction team is not left waiting for more materials. Have you run short of materials on your construction project? What was the reason? This article was first published on the ClockShark website. For construction and field service companies who want to get rid of paper time sheets, ClockShark is the GPS time tracking app that's both powerful and easy to use. Do you want to learn how to manage construction projects successfully?Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. © 2019 This article is not to be reproduced for commercial purposes without written permission from the author. construction management construction project management

6 Comments

28/6/2021 01:34:16 pm

I appreciated it when you shared that it is important to constantly check on the available construction materials and take action if there may be insufficient materials. In this way, you can prevent any delays that might elongate the process. I would like to think if a company is working on a construction project, it should consider getting the supplies from a reliable supplier.

Reply

7/9/2021 07:45:14 pm

Before a roof is repaired, you need to clean your roof first. Washing with detergent and making it free of dirt and debris will improve your results.

Reply

31/10/2023 08:49:46 pm

minimum stock of all material must be maintain to check the stock crisis. plus reordering and tracking of ordered material is must

Reply

Leave a Reply. |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed