Construction project logistics - the hidden bottleneck that could be strangling production26/6/2016 "Poor logistics will be costly on your construction project." Logistics are often overlooked when planning a construction project, yet poor logistics can cause bottlenecks which literally strangle the life out of your project. It impacts production and productivity causing delays and adding to costs. Usually the larger the construction project the more important and complicated the logistics become. Getting materials, equipment and people to the construction work siteLogistics includes mobilizing people to the project site, getting them to the project every day and then moving them around the project to where they are working. A project with a dozen, fifty or even hundred people can be simple to coordinate, but some projects can have thousands of workers. Sometimes the project may be in an operating facility which already employs thousands of workers. Somehow the construction workers have to get to their job site without impacting the owner’s workers. Then the owner’s workers still have to get to where they are required without hindrance or being endangered by the construction work. This must happen safely and quickly. Even if every person in a hundred person team is only delayed by five minutes in the day, the total impact on the project is more than 8 hours – put simply we have to employ an extra person every day to make up for the lost time. Five minutes on most construction projects is nothing and it’s often more like fifteen or twenty! Why is there poor productivity on your construction project? Some industrial and mining facilities can cover huge areas and the distanced between work locations can be significant. Lengthy delays in getting personnel to their work areas at the start of the days and after their rest breaks can reduce productivity dramatically. Then there are facilities that have extraordinary security that causes huge delays. I have for instance worked in diamond plants and precious metals refineries where security has been very strict and getting materials and equipment in and out of work areas took time, patience, paperwork and effort – tying up staff and disrupting progress and productivity. Vertical transportation in high-rise buildings can be particularly challenging. I’m sure we have all experienced frustrating delays on these projects waiting for hoists to take up men and materials, or cranes to lift materials to where they are needed. Logistics is about getting materials and equipment from their point of origin to where they are needed at the work face at the correct time and without damage. Logistics includes offloading the equipment and material safely, and installing them when required. Do Your Material Deliveries Suck? How to avoid problems Some material and equipment can be over-sized – either being extra wide, long or high or very heavy. Special transport may be required as well as permits and escort vehicles. Can the roads leading to the project site handle these loads? Are the roads on the project site designed for these loads? We need to consider radii of bends, road widths, height restrictions and weight restraints. In addition projects are changing on a daily basis and routes may become restricted or even dug up. What could be a simple exercise of getting an item onto site at the start of the project can turn into a nightmare later as structures are built and roads are changed. Many contractors have suddenly found routes unsuitable part way through the project when new bridges were built over the road restricting the height of loads that can use the route. planning deliveries to construction sites Construction Cranes"Projects frequently don’t have sufficient cranes or material handling equipment." Projects frequently don’t have sufficient cranes or material handling equipment. This lack of equipment not only delays getting the materials to where they’re required but could also delay offloading the trucks bringing the material to the project. These delays impact productivity, delay trucks from returning to collect the next load (meaning more trucks are required) and can lead to additional costs from transport companies whose trucks are delayed. Double handling and even triple handling of materials is a result of materials being off-loaded in the wrong place, or materials arriving ahead of time and the work area isn’t available. The additional handling of the materials results in additional costs but it can also risk damaging materials and equipment. Lifting operations need to be done safely with trained personnel. Improperly rigged loads can cause accidents resulting in injury and damage to equipment. Lifting operations can be delayed because of wind, equipment breakdowns, inexperienced operators, poor rigging and slinging techniques, cranes being incorrectly positioned, repeated moving of the crane between loads or workers installing the equipment and materials not being properly prepared. Too often work areas aren’t ready for items that have to be lifted, leaving expensive cranes standing idly waiting, while other areas are themselves waiting for the crane. Proper organisation and planning of work areas can free up the cranes to do more work. Cranes, lifting equipment and slings Crane congestion can be a major problem – especially on large contracts with many different contractors and subcontractors, each with their own crane. This can lead to dangerous situations which need to be avoided such as the risks of crane booms clashing and cranes lifting loads over workers. At the very least it leads to reduced productivity. A major part of logistics is about getting the right item arriving on the project site at the right time. We need to ensure that suppliers have a delivery schedule which they stick to. Far too often we receive the materials we require last before the items we require first. This leads to a congested work area and double handling of materials. Storing materials on construction projectsOften projects don’t consider the laydown areas where materials will be stored before they are needed. These areas may have restricted access. Sometimes they aren’t cleared and leveled properly which could lead to dangerous situations when trucks and cranes are parked on sloping ground. This might result in them overturning. Materials stacked on sloping ground could also over topple causing damage and even serious injury. These storage areas need to be well drained so stormwater can drain away. I have seen storage areas flooded resulting in damage to the materials or at best the material storage area couldn’t be accessed until the water was drained away. Storage areas also should be firm underfoot so that trucks, cranes and the materials don’t sink into the ground. Crane outriggers sinking into the ground can lead to dangerous situations of the cranes overturning. Materials must be stored in such a way that they don’t become damaged by the elements or contaminated. Materials must be easily accessible and when necessary so the oldest materials can be used first. "Construction materials must be easily accessible." Good logistics are important for the success of your construction projectMany contractors don’t plan their project’s logistics well resulting in delays to the project, additional costs and in some cases even damages to materials. Contractors sometimes just place an order for an item of equipment or materials required for the project without considering how the items will get to the project, how they’ll be off-loaded, where they’ll be stored and how they’ll be installed. Well thought out logistical procedures and plans will pay dividends to your project. 10 reasons your project is behind schedule (programme) This article was first published on the ClockShark website - Get The Industries' #1 Time-Tracking AppRunning a field service or construction business takes coordination and a great team. With ClockShark you get the industries' #1 timesheet app Please share this post Learn more about Construction Project Management"It is a very easy to use book with guidelines that are referenced intelligently with case studies." To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

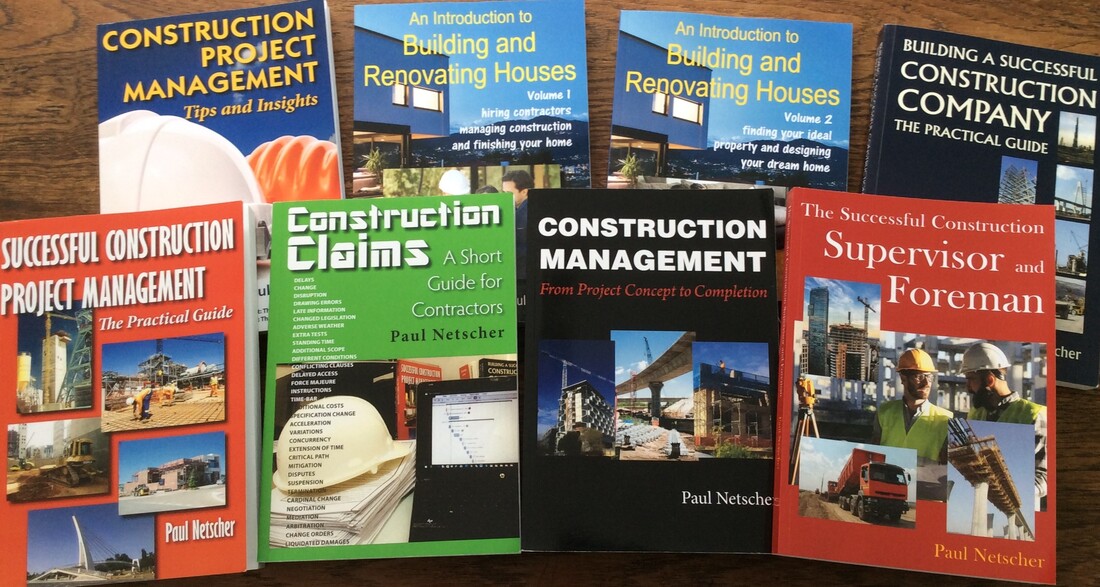

'Successful Construction Project Management: The Practical Guide' 'Building a Successful Construction Company: The Practical Guide' 'Construction Claims: A Short Guide for Contractors' 'Construction Project Management: Tips and Insights' 'Construction Book reviews' To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you Order your books from Amazon Order your books from Amazon UK © 2016 This article is not to be reproduced for commercial purposes without written permission from the author. construction management construction project management

0 Comments

Leave a Reply. |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed