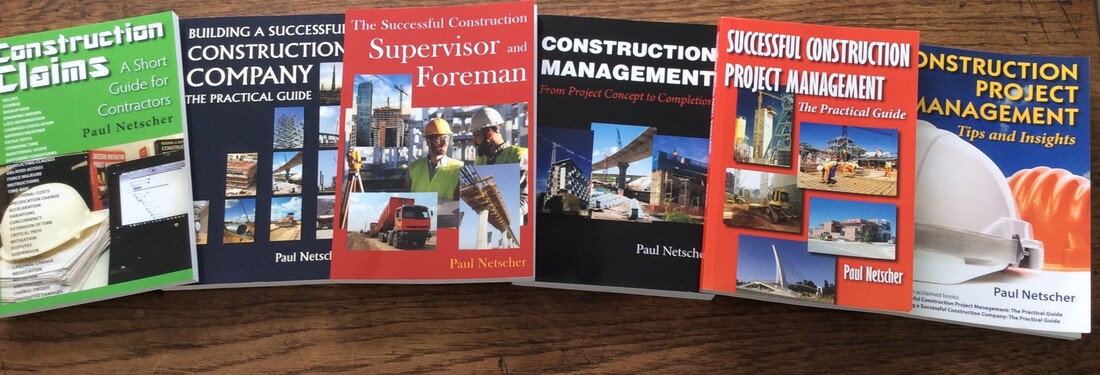

Are you losing construction projects because your price is too expensive?When clients and project owners prepare project budgets for construction projects they often confuse real costs, estimates, and contingencies. This can result in construction budgets that are too low, meaning they run out of money before the project is completed. Alternatively, when construction budgets are too high the project appears to be too expensive and nonviable and it’s cancelled. Contractors also confuse real construction costs, estimates, and contingencies when they price construction projects. If their price is too low then they lose money when the construction costs exceed the price they agreed with the client. Alternatively, if their price for the construction project is higher than other contractors’ prices then they won’t win the project. How to calculate construction contingency costsLet’s look at a simple analogy. You decide that you are taking the family for dinner at a restaurant. How much will it cost and what restaurant can you afford? When you assume the costs based on known information If you’ve been to the restaurant before you might have an idea of what the average meal costs. So you calculate that there are four people and assume that each person chooses an item that costs $20, and they order drinks that cost $10. Now, this is a guess based on previous experience. You could add a contingency of 10% to these prices, so the $20 has a $2 contingency and the $10 has a $1 contingency. So your estimate is $132 – which is 4 people at $30 plus 10% contingency. When you have little information (you're guessing a price) Now if you hadn’t previously visited the restaurant, then you’re going to be less sure of your estimate of the cost of the meals. Maybe again you estimate $30 per person and you then add a contingency of 15%, so your estimate is $138. But some might add more contingency. Say, it’s your partner’s birthday, maybe they’re going to splash out and spend more, possibly even have a desert. So you add a 50% contingency for their meal. Your cost estimate will then be 3 x $30 plus 1 x $30 + 50%. This is $135. Then you add 15% contingency to this total estimate and your budget is $155.25. This might now be more than you’re willing to pay so you cancel your dinner plans – tough on the family. But see what we just did. You added 50% to one meal, then added 15% on top of the 50%. You’ve actually added 72% to one meal and the $30 is now $51.75 – is this realistic? You’ve added contingency on top of contingency! Yet, frequently that’s what contractors and clients do. When your estimate is too high you can reduce the contingency But, in the above example, we’ve only assumed the worst-case scenario that everyone’s bill is more expensive than the estimate. Is there a chance that one of your kids only orders a kids meal and a soda? Maybe there’s a possibility that your estimate for the children of $30 is too high. So why add a contingency to their meal? In this case, you could add 5% to 2 people’s meals and 10% to the other 2, or an average of 7.5%. Your budget is now $129. This might seem a small difference, but often contractor’s win projects with a price only a few percentage points lower than other contractors’ prices. When you know the exact cost Often you even know what some costs are, so it’s unnecessary to add a contingency to your known costs? Sticking with the restaurant analogy, maybe you know that the restaurant has a kid’s special including drinks and the price is $20. That’s what you will order for your 2 children. So, we have 2 meals at $20 known cost and 2 meals estimated to cost $30 each. So the total is $100. But there’s still some uncertainty so we add a contingency. It’s not necessary to add contingency to the 2 children’s meals only to the adults. Adding 15% contingency only to the adult’s meals is 15% on $60 which is $9 and your budget is $109. This is much less than your first price of $132 – in fact 17% less. Applying this to construction estimatesKnown construction prices Well, when we price a construction project there are certain known costs. So, we have a subcontractor price to install the complete roof. This is a known price, a fact, so there’s no reason to add a contingency on top of this price. Then we can calculate what some things will cost and this is based on the costs of materials, labour, and equipment, and our calculation is built on our previous knowledge and experience as well as known prices for construction materials and equipment which we’ve obtained from suppliers. If we’ve done similar work before and kept track of productions and construction costs then we’ll have high confidence in our cost estimate. If it’s something new then we will have low confidence in our price. Depending on our confidence we might add a contingency on top of our price. So low confidence means a higher contingency. But. it’s pointless adding a contingency to each of our estimates, then reaching a total price, then adding another contingency on top of that figure. Not only have we added contingency to known prices such as the roof, but we’ve also added contingency on top of contingency. So for instance, if we had a 10% contingency for concrete and then added another 10% contingency to our total price, then the contingency for concrete isn’t 10% + 10% = 20% but it’s actually 21%. 10% onto 10%. If we know we have 100 cubic yards of concrete on the project we calculate the estimated cost for the concrete. This includes the cost to purchase the concrete plus the cost to place the concrete. The cost of the concrete is usually a known price because we’ve asked the supplier for a price. The unknown price (separating the known from the unknown) The unknown is the wastage. If the concrete is going into a structure contained within forms the wastage may be minimal – a couple of percents (the shape and box have precise dimensions). If the concrete is in a slab on the ground the wastage could be as high as 10% – the ground may not be perfectly level and the dips could add an extra half inch to the thickness of the concrete slab, meaning we use more concrete. Often contractors add contingency to cover them for the worst case scenario. But, is it likely that every item will reach the worst case scenario? Some items might turn out exactly as estimated, some might be as bad as the worst-case estimate and some might only be half as bad. So, in the example of the concrete slab on the ground we assumed half an inch or 10% maximum wastage, but assuming the slab will never be thinner than required, we may in some cases have zero wastage and sometimes there’ll be a half inch of wastage - the wastage varying between 0 and a half. So on average, the wastage might only be a quarter inch or 5% and not 10%. A 10% overall wastage would mean that in some areas the slab will be an inch thicker than allowed while in other places it will be the exact correct thickness. Of course if you assumed that in some places the slab was equally as thin (obviously it’s not good practice to have a concrete slab thinner than it should be) as it was thick in other places, then overall the thinner areas may balance out the thicker concrete and it wouldn’t be necessary to add any additional wastage. Sometimes contractors are asked for a quick estimate or budget price. They could take a price for a similar building or structure and then add a contingency to this price – this is a very rough estimate. If they have more time they could calculate the size of the building, then knowing the square feet apply a rate per square foot. They’ve done a bit more research so their price is a little more accurate than the first estimate, so they don’t need to add as big contingency to their cost estimate. If the contractor has more details and spends time breaking the structure into more detailed components which the contractor prices, then the contractor’s price becomes more accurate, and the contingency the contractor adds to their price becomes less. If the contractor has prices from subcontractors for all the work, then there probably isn’t any reason to add any contingency, because all the price risk lies with the subcontractors. What we see from the above is that the more research and investigation we do, the more confidence we have in the price, until eventually we have 100% confidence and we don’t have to add any contingency to our price. Conclusion - Calculating the right price for your construction project Image courtesy of fantasista at FreeDigitalPhotos.net Image courtesy of fantasista at FreeDigitalPhotos.net If a contractor’s price for a project is too low they’ll lose money on the project. If the contractor’s price is too high they’ll never win the project. The contractor’s price is usually made up of known costs (facts) and these are exact prices provided by subcontractors and suppliers. There is no need to add a contingency to these items. Then there are some items which are estimates. This could be an estimated quantity, an estimate of wastage or an estimate of the rate of production. Depending on the confidence on how the figures were derived the contractor may add a contingency to the item. But each item usually has a different degree of certainty, so the contingency added would be different for different items. Contractors must always take care that they aren’t adding contingency on top of contingency. .....Continue Reading..... This article was first published on the ClockShark website. To visit this website and continue reading the article click on the link above. Please share this post Do you want to learn how to manage construction projects successfully?I've written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. The books are available in paper and ebook from most online stores including Amazon. Need help with your construction project or construction company?Contact me for help and advice.

To read more about the author’s books and find out where you can purchase them visit the pages on this website by clicking the links below:

To read more about the author visit the page 'Paul Netscher' Want to contact Paul Netscher please enter your details on 'Contacts' Find out how Paul Netscher can help you © 2019 This article is not to be reproduced for commercial purposes without written permission from the author. As an Amazon Associate I earn from qualifying purchases construction management construction project management

0 Comments

Leave a Reply. |

Archives

June 2024

Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. Comments must be in English. We will not enter into discussion on why a particular comment was removed.

CategoriesCopyright 2016 - The attached articles cannot be reproduced for commercial purposes without the consent of the author.

The opinions expressed in the attached articles are those of the writer. It should be noted that projects are varied and different laws and restrictions apply which depend on the location of the contractor and the project. It's important that the reader uses the supplied information taking cognisance of their particular circumstances. The writer assumes no responsibility or liability for any loss of any kind arising from the reader using the information or advice contained herein. "I have what I consider some of the best books on construction management."

Books are available from: Amazon.com Amazon.co.uk takealot.com kalahari.com Amazon.in Amazon.de Amazon.fr Amazon.it Amazon.com.au Powell's Fishpond uread bokus Amazon.ca Amazon.es Other retail stores Available in paperback or on Kindle "28 YEARS OF CONSTRUCTION PROJECT MANAGEMENT EXPERIENCE, DEVELOPING SUCCESSFUL CONSTRUCTION PROJECT MANAGERS AND BUILDING SUCCESSFUL CONSTRUCTION COMPANIES"

|

RSS Feed

RSS Feed