|

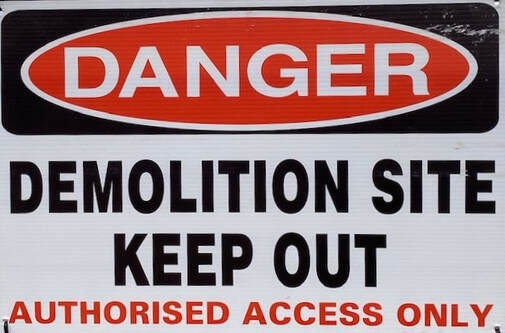

Sometimes construction projects involve demolition of existing structures. On occasion clients change their minds after a structure has been built and they require the newly completed structure demolished, or a hole cut in it. Regrettably, on occasion contractors make mistakes, or work is of a poor quality, so a completed structure must be broken down. Demolition work is often dangerous and must be done with care. Some examples of demolition accidents https://www.abc.net.au/news/2019-09-04/sydney-booty-parlour-gym-destroyed-by-mistake/11476874 https://www.constructionenquirer.com/2020/01/15/worker-killed-as-excavator-falls-through-concrete-slab/ https://www.amny.com/editorial/two-workers-seriously-injured-when-wall-collapse-drags-down-scaffolding-during-harlem-demolition/ Cutting and demolishing safely on your construction projectBefore demolitions starts, all hazardous materials must be identified and removed separately, where required demolition permits must be in place, electrical, gas and water supplies must be cut-off to the structures and the lines made safe, all salvageable material should be removed, safety steps must be in place to prevent injuries to workers and the public, exclusion zones must be clearly marked and enforced so that falling debris don’t injure people or damage property, steps must be implemented to minimise dust, areas to be demolished or removed must be clearly marked so that there’s no confusion or risk of the wrong structure being demolished, the right equipment must be used (equipment that’s too big may result in excessive vibrations or loads damaging other structures) and rubble should not be allowed to accumulate where it could block access or cause overloading to structures. But, even on a normal construction site, often contractors have to cut or drill holes through walls and concrete slabs to make way for pipes and utilities. Cutting a wall brace could make the whole structure unstable, and it could collapse when there’s a strong wind or an external load is imposed on the structure. It’s hard to think that cutting one brace (sometimes only a few inches thick) could cause a whole steel structure to collapse, but unfortunately it has happened. Similarly, care must be taken when cutting holes in a concrete floor slab. Cutting through vital reinforcing could weaken the slab causing it to sag and crack. Some concrete slabs have tensioned cables and cutting one or more of these can lead to a serious failure. Therefore, always take care when cutting structures, in fact check with the design engineer that the hole can safely be cut there. Always check first before cutting. ConclusionCutting and demolishing structures can be dangerous. Always thoroughly understand the risks and make sure the team takes the appropriate safety measures. Where necessary have an engineer check the structure before cutting or demolition works start. Always check that you are cutting in the right place - you wouldn't want to cut an opening in the wrong place, or demolish the wrong structure. Other useful articles Expect the unexpected in construction Damaging existing services Managing subcontractors on your construction project. What you should consider.  This article is an extract from the book 'The Successful Construction Supervisor and Foreman'. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon.

5 Comments

As long as we’ve had houses and other structures, we’ve had people who specialized in building them. Until the last 100 years or so, though, the idea of safety in the construction industry just didn’t exist. How has construction industry safety improved over the years, and what advances are we still making to ensure workers are safe on the job? A Brief History of Construction SafetyOne hundred years ago, construction safety looked a lot different than it does today. In the late 1800s and early 1900s, there were no safety measures to prevent people from getting injured or even killed on the job. While employees had the option to sue their employer for damages, their chances of winning were slim to none because employers weren’t liable for these incidents. The U.S. government didn’t establish the National Safety Council until 1913, and it wasn’t until 1921 that a majority of the states had some sort of Workers’ Compensation laws on the books. OSHA, the Occupational Safety and Health Administration that we so often cite as the construction safety “bible,” didn’t make its appearance until 1971. Even with all the advances made over the past century, there were still 3.5 fatalities for every 100,000 workers in the sector in 2019. Safety on the Modern Construction SiteConstruction site safety is something the industry is constantly trying to improve, with varying levels of success. Despite this, one out of every five workplace fatalities happens in the construction industry, the highest across every sector. What can companies do to improve safety on their work sites? A safe work site starts with comprehensive and continual safety training. Everyone should receive the same training, and that shouldn’t stop once a new hire has completed their onboarding. Visitors and anyone who doesn’t work for your company should either be barred from entering the job site, or should be accompanied by a trained employee at all times to prevent incidents. In addition to training, employees also need the tools and equipment to do their job safely. This should include, but not be limited to, personal protective equipment (PPE) like hard hats, safety goggles, ear protection, and gloves. All equipment and PPE needs to be maintained so it’s in good working order, and repaired or replaced as needed. Read 5 traits of the safest contractors. Keep in mind that you will need different sizes of PPE for your various crew members. This is one part of life where one-size-fits-all just won’t cut it. Looking ForwardConstruction safety has come a long way in the last 100 years, from a time when we had no safety rules whatsoever, to now, when we’ve got plenty of rules to keep us safe. It’s not a perfect system, but it’s been a series of strong steps in the right direction. Author Bio: Rose Morrison is a freelance writer who covers construction and building design topics. She is also the managing editor for Renovated. Other Useful Articles How poor safety costs your construction company money Who is responsible for safety on your construction project? Construction projects and high temperatures - do you know the risks? Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Frequently construction projects end over budget, are finished late, are of poor quality, cause injury or death to workers and even to those using the project after it's complete, contractors loose money on the project, or the project ends in protracted and expensive legal battles. How can we improve construction project outcomes for all parties - client or owner, contractor, subcontractors, and suppliers? Is it possible to have a project win-win for all parties? How can we improve the success of our construction projects? It is possible to improve the success of construction projects with better collaboration. How to improve collaboration on construction projectsSome say that collaboration can be improved by using technology. How will this happen? Can new forms of contract improve collaboration? Who is responsible for improving collaboration on construction projects? Join me with this presentation I gave as a CPD webinar as I share my thoughts and experience on how we can improve collaboration in the construction industry.

Other useful articles: Why construction projects go wrong before they even start – what should owners do? Why owners sometimes employ the wrong contractor Do You Have Good Communication On Your Construction Project? Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Frequently construction projects end in long and acrimonious disputes which can be costly, consume large amounts of time and energy, and which sometimes drag on long after the project construction work is complete. These disputes may end inconclusively with no winners - except perhaps the lawyers. These disputes occur between clients/owners and contractors, between contractors and their subcontractors and suppliers. In my last article Avoiding Construction Disputes I mentioned that I had resolved hundreds, probably more than a thousand, variation claims (change orders) with my clients amicably and without declaring a dispute. Some recent examples of disputes https://www.santafenewmexican.com/news/local_news/eldorado-hotel-sues-designers-builders-of-rooftop-swimming-pool/article_fe18b412-90b8-11eb-aafb-33f9dd971cfc.html https://www.cincinnati.com/story/news/2020/09/02/forest-hills-says-subcontractor-has-grossly-exaggerated-money-due/5684289002/ https://therealdeal.com/miami/2020/09/09/miami-river-condo-association-alleges-10m-in-defects-lawsuit/ So how can we prevent disputes on our construction projects? How contractors can avoid construction disputesContractors can avoid disputes if:

How clients and owners can avoid construction disputesEmployers can avoid disputes by:

ConclusionCollaboration between contractors and the client or owner, collaboration between contractors and their subcontractors, a team effort can lead to a successful construction project for all. Good communication is essential to successful projects. Aiming for a project that is a win for everyone, rather than a winner take all approach. It is possible to avoid construction disputes. Other useful articles: Why owners sometimes employ the wrong contractor Are your subcontractors profitable? Should you care? what makes a good client?  This article is from the webinar Avoiding Construction Disputes by the author and information included in author's book Construction Claims: A Short Guide for Contractors. This easy to read book demystifies the claims (change order) processes ensuring entitlements are claimed. Learn when you can claim, how to make claims compelling, and the supporting documentation required to win. Your eyes will be opened to numerous events, costs and impacts. Knowing some of these tips could dramatically improve profits and avoid time consuming acrimonious disputes. Also included is advice for contractors to avoid and defend claims from employers and subcontractors. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Regrettably, some construction projects end in long and acrimonious disputes between the employer and contractor, or between the main contractor and subcontractors. These disputes appear to occur more often these days. Frequently the only real winners from these disputes seem to be lawyers.

"Submitting a variation claim (change order request) is not a dispute. A dispute arises when the contractor and the employer cannot agree that the variation claim (change order) is legitimate, or they cannot agree the quantum of the claim." Disputes also arise when one party does not fulfil their obligations in terms of the contract despite repeated requests from the other party to comply. For example; the employer does not pay the contractor, or the contractor fails to rectify faulty work which is due to their fault. Although disputes are often characterized by a formal dispute resolution process, many disputes simply result in a breakdown in communication between the parties, threats, unhappiness, and a prolonged social media and mainstream media slanging match, which can lead to damaged reputations and be a distraction. Many disputes are left unresolved and fester on, while sometimes the slanging match leads to a further dispute, or legal action. Examples of disputes gone wrong: https://floridapolitics.com/archives/316849-downtown-st-petersburgs-bliss-condo-owners-sue-developers-over-shoddy-construction https://therealdeal.com/miami/2020/08/03/codina-partners-affiliate-allegedly-owes-3-6m-for-downtown-doral-condo-construction-lawsuit/ https://www.chicagolawbulletin.com/nixon-peabody-get-3-6-million-attorney-fees-20200602 Is it possible to resolve variation claims amicably without declaring a dispute?

Reasons for construction disputes

In the next article we will discuss why construction disputes are bad for the parties, and how to avoid construction disputes. How to avoid construction disputes Other useful reading: Don’t start construction projects without a proper contract Is Your Construction Correspondence Losing You Variation Claims or Projects? When Contractors Can’t Claim a Delay From Their Client on Construction Projects  This article is from the webinar Avoiding Construction Disputes by the author and information included in author's book Construction Claims: A Short Guide for Contractors. This easy to read book demystifies the claims (change order) processes ensuring entitlements are claimed. Learn when you can claim, how to make claims compelling, and the supporting documentation required to win. Your eyes will be opened to numerous events, costs and impacts. Knowing some of these tips could dramatically improve profits and avoid time consuming acrimonious disputes. Also included is advice for contractors to avoid and defend claims from employers and subcontractors. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. From time to time construction projects are delayed by events outside the control of the contractor and due to no fault of the contractor. Also, on some projects there are scope increases which may require extra time to complete. Contractors need to submit a delay claim (change order) requesting an extension to the milestone completion dates. This extension is necessary to avoid penalties or damages being imposed by the client. In addition the contractor can usually request to be reimbursed for the costs associated with the additional time. Most contractors believe that using the approved Construction Schedule (Programme), with linked tasks and a Critical Path, they can simply input the delays and automatically get a new end date. Essentially this is true, but it doesn’t take into account some factors which could impact the new revised Construction Schedule. What to consider when your construction project is delayed1. The revised Construction Schedule may push certain activities into unsuitable weather seasons. For example 1: the contractor may have planned to complete the excavations and earthworks in the dry season, but because of delays these activities are now pushed into the wet season. In some areas it can be impossible to carry out earthworks in the wet season, but at the very least the rains will cause additional delays which weren’t allowed in the original Construction Schedule. Example 2: the original Schedule was prepared on the premise that the building being constructed would be weather tight by the time severe cold or rains arrived. Delays to construction could result in the building not being weather-tight before the onset of poor weather resulting in weather related delays which weren’t allowed in the Construction Schedule. 2. The revised Construction Schedule can cause underutilisation of construction resources and equipment, such as large cranes which may have to be re-established again on the project, or could be under-utilised for a period. 3. The revised Schedule may have resource peaks and troughs. This might result in resources (men and equipment) having to be removed and re-established on the construction project resulting in additional costs. In fact will you be able to find the additional resources for these peak demands? 4. Pushing out the end date of the project may mean that specialist subcontractors and equipment might not be available as they are already committed to other projects. Case study: On one earthworks project that was both delayed and increased in Scope, most of the equipment had been ordered for the original project duration and was committed by the supplier to another project at the end of this time. At the end of the original contract period the supplier removed all their equipment, even though we weren’t finished using it, and we had to source new equipment which caused us delays and additional costs. 5. Construction materials that have already been ordered may have to be delivered to the project site in accordance with the original Construction Schedule, even though they are no longer needed at that time. This could result in the site becoming congested. Also, the materials probably now have to be double handled, possibly necessitating additional transport and cranes to move them. The alternative is to store the materials and equipment off-site at an additional cost which would include security and unloading and reloading them. There’s also the additional risk of damage to these items with the extra handling and storage. In addition the contractor usually has to pay for these items because they’re considered delivered by the supplier, but the employer may not pay the contractor for them until they are installed, which will be in accordance with the delayed Construction Schedule – with sometimes dramatic consequences for the contractor’s cash flow. 6. Moving the Construction Schedule out could also move the Schedule to coincide with statutory public holidays. These holidays cause further delays. In some countries projects shut-down for an extended period over Christmas. Again this period further delays the project. But in addition if the original plan was to have finished the work before this holiday shut-down the contractor will now face additional costs of having to secure the project site and maintain their site facilities over this period. 7. In some cases the contractor may have planned their Schedule so that major concrete pours occurred before the holiday period. The concrete was planned to cure and gain strength over the break so no time was allowed in the Schedule for this activity. A delay may thwart this plan meaning that the concrete is only poured after the break and the curing time has to be added to the Schedule. A delay of a couple of days could impact the schedule by several weeks. Other Useful reading: Negative cash flow – the death for many construction companies Will your next construction variation claim be successful? Construction project variations – have you included all your costs? ConclusionFormulating a construction delay claim, extension of time claim (change order) is not always straight forward and there is much to consider. What are the knock on impacts of the delay, both in cost and time? Having a detailed Construction Schedule (Programme) showing all the links, the critical path, and a Schedule that is fully resourced is an essential starting point. Of course it's also helpful if you included with your Schedule submission to the client certain key assumptions you made when formulating the Construction Schedule. This could include work that had to be completed before the start of the wet season, or concrete that needed to be poured before the holiday period. Prepare your delay claims carefully to ensure you have not overlooked anything. Then make sure you detail in your claim all the impacts and costs. You normally have one shot to get it right.  This article is an extract from the book Construction Claims: A Short Guide for Contractors. This easy to read book demystifies the claims (change order) processes ensuring entitlements are claimed. Learn when you can claim, how to make claims compelling, and the supporting documentation required to win. Your eyes will be opened to numerous events, costs and impacts. Knowing some of these tips could dramatically improve profits and avoid time consuming acrimonious disputes. Also included is advice for contractors to avoid and defend claims from employers and subcontractors. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Love them or hate them we all attend meetings and even call meetings. These days many meetings are held remotely via Zoom, Microsoft Teams, and similar, which at least saves travel time. Yet even so we still bemoan the fact that meetings waste time and often achieve little – even though sometimes we called the meeting. In construction we seem to be always attending meetings. Meetings with the client, subcontractor meetings, staff meetings, and more. Some managers seem to love calling meetings. A meeting to discuss this, a meeting for that. Sometimes these meetings are a complete waste of time without any firm resolution or outcome. But, some meetings are important, and a properly managed meeting can yield satisfactory outcomes - yet even these meetings can waste more time than they should. Can we cut down on wasted time and get value from our meetings. Well let’s look at the top reasons meetings waste time. Avoid these 12 meeting time wasters1. Meetings must start promptly. Most meetings start 5 or more minutes late. If there are 6 people at the meeting then in total 30 minutes have been waste. Why do meetings start late? Well it’s often due to someone being late. How selfish of them to keep everyone else waiting! Meetings should start on time, even if there is someone missing. Insist that everyone is on time – tardiness should not be tolerated. Of course another reason for a late start is that some attendees are engaging in chitchat while others look on waiting patiently to get down to business. 2. People must arrive on time. This sounds similar to point 1. But even when meetings start promptly time is wasted when the chairperson has to recap what has been discussed previously for the benefit of late arrivals, sometimes even giving them an opportunity to reopen some of the agenda items that have already been discussed and closed. When there are several late arrivals who trickle in at different times the recap can be repeated. Sorry, the late arrival can read what they missed in the minutes. If the person who is late is required to give input into an item on the agenda then that item could be set aside for discussion when they arrive, and the meeting can move onto other items in the meantime. Why bore those who bothered to arrive on time with these recaps, wasting their time in the process. 3. Have an agenda. An agenda must be sent out before the meeting so that people can prepare for the meeting. If necessary the agenda should have sufficient detail to ensure that particular items are discussed and that people come prepared. So for instance only to have ‘Quality’ on the agenda may not be sufficient. Under ‘Quality’ you may need to add subitems like, ‘Progress on Snag or punch-list items’, and ‘Closing out of non-conformance reports’, and ‘Status of quality documentation’, and ‘New quality problems’. Then people know what will be discussed and can hopefully be prepared with the information. The agenda also ensures items aren’t forgotten in the meeting. 4. Stick to the agenda. Some people love hearing the sound of their own voice. It never ceases to amaze me what some talk about in meetings – items which have no relevance to the agenda, and even to the overall reason for the meeting. I think some people just want to show how important they are, or how busy they have been. If you’re not adding to the topic under discussion shut up. The chairperson should keep tight control on the meeting cutting short off-topic talk – or suggesting the conversation continues after the meeting. Then you have people who bring up items which should have been discussed under a previous agenda item, or that is relevant to an upcoming agenda item. Again. Stick to the agenda and discuss items at the relevant time. 5. Representatives who attend the meeting must have the authority or knowledge to contribute to the meeting. So we get comments like I don’t know, or I can’t commit to that until I’ve spoken to my manager. Or, worse, when their manager gets the meeting minutes they don’t like what their junior committed to, or said, and they dispute things agreed or said by their representative – thus wasting everyone’s time. 6. People attend attending the meeting should benefit from attending the meeting. Often people are invited for fear of offending them if they aren’t included. Ensure only those relevant to the discussions attend. From time to time it may be necessary to explain to someone why you don’t think they required to attend – I’m sure they’ll be only too happy to be excused. 7. Everyone should be prepared for the meeting. Read through the minutes before the meeting and ensure you have all the required info and questions ready for the meeting. 8. Don't argue over small points that are of little consequence. Sometimes people argue points, or try and justify things, even when they know they are wrong. Learn to admit when you are wrong. Move on. Anyway, somethings are inconsequential in the big picture. After all it’s about getting the project done. 9. Meetings should have outcomes. Frequently items are left unresolved, or a meeting is scheduled to discuss the item again. Be clear in the meeting minutes or meeting record what was decided at the meeting. If there’s an action for someone then the minutes or meeting record should name the person to action the item, and preferably a completion or due date to complete the task. 10. Meetings should not be side-tracked to discuss detail issues which only affect a couple of participants. When the detail of an item comes up that does not affect the meeting and other attendees learn to ask those involved to discuss the detail after the meeting. 11. Keep emotions and egos out of meetings. Stick to the facts. Meetings are not a place to air personal grievances, or make insults and derogatory comments about individuals. Sometimes it's best to ignore others who make personal comments, or when the discussion becomes personal and heated. 12. Meetings should not be rescheduled, or deferred, at short notice. This inconveniences people who have planned for the meeting, and they often have to reschedule their time, even reschedule their other meetings. Keep to the schedule. Ensuring meetings are beneficialOften it’s good practice to have meetings. Properly organised and managed meetings can resolve issues more easily than a stream of emails. Putting all the people in the same room – physical or virtual – allows people to ask questions and come to an agreement. It’s important that there is a record, or minutes, of the meeting. The person leading or chairing the meeting needs to sometimes lay down the law, even perhaps be rude on occasion, to ensure that the meeting does not waste time and maximises outcomes. Of course this does not mean cutting people short so that alternate opinions or positions aren’t discussed, rather it’s about sticking to the purpose of the meeting and keeping the discussion on track, and where necessary reaching agreement and setting direction. Are you guilty of wasting time at meetings? What do you do to keep meetings as short as possible and ensure they achieve satisfactory outcomes? Other useful articles: Time management Daily reports How you can make your next construction project more successful. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. I frequently get asked how many workers can a Supervisor or Foreman look after? Or, how many people do I need to supervise and manage my construction project? Well the answer to these questions depends on a number of factors which we discuss in this article. I’ve often been on construction projects which were understaffed. In fact I’ve probably been guilty of having too few staff on many of my construction projects. This creates stress for the Project Manager and other staff, often resulting in them working excessive hours, sometimes making inappropriate decisions because they’ve not had time to analyse the facts correctly. Safety and quality are compromised because staff spend inadequate time on the project site ensuring the work meets the required standards. Details get overlooked. Productivity of the workers is often poor since they are not supervised effectively and don’t have the materials and equipment to execute the tasks because their managers haven’t ordered them. Of course the converse is also true and the construction project shouldn’t be over-staffed with too many managers and supervisors. Too many people not only leads to inefficiencies and additional costs, but can result in people becoming bored. What impacts the staffing on construction projectsThe number and type of staff required for a construction project depends on a number of factors including:

Do you always require the best and most senior people for a project?Sometimes the contractor doesn’t have to use their most senior or experienced staff on a construction project; in fact sometimes senior staff can be detrimental on small construction projects as they:

Important notes for staffing construction projectsStaff must:

The project should have an organisation chart which shows the staff, their positions, responsibilities and reporting structures. Other Useful articles: What does it take to manage a construction project? Before starting your next construction project ask these questions how to effectively manage construction projects with a large workforce  This article is an extract from the book 'Building a Successful Construction Company: The Practical Guide.' © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. The construction industry like any other industry has evolved during the years bringing innovative projects that will mark the future. Striving for change and transformation, this industry has introduced numerous tech solutions that focus on successful project delivery, and better collaboration and communication among managers, planners, and overall team members. In the article that follows, we will explain how construction management software solutions become the leading power in the industry, plus we will touch base with the top five apps to manage construction projects. What is Construction Management?The practice of planning, analyzing, monitoring, and overall managing construction projects from start to finish is called construction management. The goal of construction management is to deliver construction projects successfully on time and on budget. Being a complex practice, the best way to manage construction is to use construction management software. The Rise of Construction Management Software Solutions At its most basic, construction management software helps project planning and control through various operations such as estimation, budgeting, scheduling, resource coordination, and the effective use of a project’s time, cost, and quality. In brief, construction management software has been created to simplify the communication between project participants, increase transparency, share documents in a timely manner and develop techniques for resolving conflicts. Not long ago, construction project management consisted of documentation and methodology. Even though the focus of the construction industry has always been successful project delivery, there was limited use of project management software. This eventually produced a lot of documents and managing resources through them was hard and painstaking. However, as a result of technology expansion, planning and running construction projects became much more complex. Traditional methods and processes became unable to handle larger budgets, integrate multiple disciplines, manage the increased number of project participants, tighter schedules, stringent standards, etc. This was especially evident in the construction industry when companies started to waste millions of dollars every year due to a lack of project planning, organizing, and data transparency. Many managers faced cost-control boundaries, and inadequate communication, which lead to not having a common understanding of the project’s state at any given time. Under such circumstances, the daily efforts were not aligned with the project goals and tasks. Furthermore, the construction project was unable to be observed as a system due to the absence of efficient real-time reporting infrastructure and task management software. Companies fail to forecast and calculate labor productivity for the next period, which causes the unavailability of resources for equipment and materials. This mindset led to poor productivity and systematic issues making it impossible to reach a deadline while staying and passing quality standards. The need for implementing a managerial tool in construction management practices was inevitable. The main objective of this tool was to increase the efficiency and accountability of everyday tasks such as planning, designing, estimating, and developing effective communication between project participants. Top 5 Construction Project Management Software With the varying number of construction tools that exist, it can be confusing to decide which software best fits your needs. To help you find the best solution, we cover the top 5 construction management software: 1. Oracle Primavera P6 – The Standard for Planning and Scheduling With over 30 years of existence, Primavera P6 has been considered as a standard for project-intensive industries. Developed to help companies optimize resources, this software provides solutions to plan, build, and manage projects of all size by using real-time data. Robust, and easy-to-use, it the software integrates project and portfolio planning and delivery teams for planning, resourcing, risk mitigation, scheduling, and program management. Basic features:

Providing standards for planners, schedulers, and project controls, Primavera P6 has opened the market for new third-party tools to enhance its working environment by introducing XER files. There are many solutions that can be used along with P6 such as viewers that allow you to open .xer project schedules without a P6 license. Also, some of these XER viewers provide possibility for analyzing project schedules and generating reports. 2. Procore – Connect everyone on your project with one platform. Procore is one of the most popular cloud-based construction management platforms in the market that helps construction firms manage risks and build quality projects. This app has user-friendly interfaces. The platform includes features like bid management, daily logs, job site tracking, emails, meetings, project photos, punch lists, RFIs, scheduling, project specifications, submittals, timecards, and transmittals. Basic features:

Procore gives your team access to review, create, edit, and share project data with team members from various locations. Along with project management, Procore keeps team members together even if they are in different locations. 3. BIM 360 – Connect your workflows, teams, and data. As a cloud-based construction management tool, BIM 360 is developed to suit engineers, architects, designers, contractors, and other construction professionals. It is designed to help project members to make informed decisions, to speed up the delivery of their projects adhering to industry standards and project specifications. Basic features:

BIM 360 enables managers to have absolute control over their project and resolve issues faster because of dashboard coordination, design visualization, and racking real-time data. This software is part of the Autodesk Construction Cloud. 4. Powerproject Designed to support construction planners, Powerproject is one of the leading project management software solutions for construction. It is available as a standalone, enterprise, or cloud app that combines drag and drop functionalities with numerous features. Basic features:

5. Corecon – Cloud-Based Construction Software Designed to optimize collaboration and workflows, Corecon integrates stored information into a singular database to maximize project profitability. The software suite helps contractors better track leads and projects, as well as manage bids, contracts, and documentation. Moreover, Corecon provides various modules for estimating, procurement, vendor bid management, documentation, time tracking, and more to ease the work of all team members. Basic features:

Corecon can be accessed via browser or mobile so your team can make quick and informed decisions regardless of the physical location. Closing ThoughtsWhat is the best construction management software solution after all? All software solutions have similar features, but the same goal: to help construction managers deliver projects successfully. In this article, we reviewed 5 solutions that will narrow down your choices when choosing a construction management app. Each platform is suitable for construction projects of different sizes and data complexity, you only need to find the one that best suits your needs. About the Author Vivien Goldstrong is a Consultant, Author and Planning Manager with 22 years of experience and expertise in implementation and consultancy related to Oracle Primavera P6. You can read her blog here: https://projectschedulepro.com Other useful articles 10 reasons why a construction schedule/program is useful project scheduling - the relationship between time and cost requirements of a Project schedule Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Every commercial building needs to have the latest upgrades to achieve exceptional functionality—one part of the building you need to keep an eye out for frequently is the roof. While you may think it’s merely a roof, you should remember that it protects the people inside your building. Moreover, modern roofs nowadays can do more than protect everyone inside from outside elements. If you are working in the construction industry, you need to know the different commercial roofs you can install for your projects. Each roof can provide specific advantages that will suit your needs, but they have the same role: to protect your building’s interior. It would be best if you knew about them to know what roof type the contractors should use for the construction project. 1. Metal Roofing The first roof type that you may have seen everywhere is metal roofing. Metal roofing is a popular choice for residential and commercial buildings because they are affordable and relatively easy to install by roofing contractors. However, metal roofing has variations because manufacturers mix other metals to create another type. Here are several examples of metal materials for roofing:

While using metal roofing is cheap, you should know that it’s susceptible to rust, especially when exposed to prolonged weather elements such as rain, snow, and heat. But what makes metal roofing the best option for some commercial building owners is its attractive, finished look. Another benefit of it is that it’s fire-resistant, so you won’t have to fret about your roof catching on fire anytime soon. If you want a durable roof than most traditional commercial roofing choices, you should choose metal roofing. 2. Membrane Roofing Another commercial roofing type you might want to install is membrane roofing, also known as flat roofing. You can find that most commercial and industrial buildings have membrane roofing because of its many benefits. It comprises multiple layers of different roofing materials, but nowadays, you can find single-ply membranes. The reason most buildings have membrane roofing is that it’s relatively easy to install, ensuring you get to enjoy your new roofing at a moment’s notice. Another great thing about it is the lost-cost maintenance. For other roofing options, you might need to spend extra dollars to get it fixed or maintained. 3. Modified Bitumen (MB) Roofing The modified bitumen roofing is closely related to the Built-Up Roof (BUR), and it is asphalt-based roofing material. Roofing contractors would specifically install it for commercial buildings with a flat roof surface. In most cases, roofing contractors install MB roofing systems to rooftops as a two-ply system, stuck to the roofing deck for maximal protection and stability. Like with the membrane roofing, you only need minimal maintenance for the MB roofing, and you can easily have maintenance personnel clean by washing. They provide maximum tensile strength than other flat roof types that sustain heavy foot traffic. If you have people visiting and walking on the roof most of the time, you should choose MB roofing as your roofing material. During maintenance season, you should install a roof hatch on your building to provide easy access to the roof. Most facilities install it because roofing contractors and maintenance personnel don’t need to prop a ladder to the building’s side. All they need is to go to the top floor, climb up the ladder, and go through the roof hatch. If you want to learn more about it, visit Best Roof Hatches’ website today! Author Bio: Best Roof Hatches is a trusted supplier for your roof hatches needs or for any commercial construction roofing project. For more inquiries or more help, visit our website. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Have you had to go back to a project long after completion to fix something? Was it easy? Did it cost money? Did you enjoy it? Covering up defective constructionOften Contractors turn a blind eye to potential quality problems. Mistakes get covered up by dirt, concrete, sheeting and paving. Hopefully never to be found by the Client, or anyone else in the future. Some Construction Project Managers are adept at walking Architects, the Client and Quality Inspectors past poor quality. It’s sometimes easy to distract the person and get them to look elsewhere, or temporarily block the offending work from view. Some Contractors even carry out clandestine operations after hours to quickly ‘patch’, or hide, defective construction work. Unfortunately often these defects manifest themselves later – sometimes with devastating consequences with loss of life such as collapsed buildings. The cost of ignoring building defectsContractors are usually responsible for repairing visible construction defects for a period of 3 to 12 months after the construction project has been completed. But defects that have been hidden, will have to be repaired by the Contractor when these problems eventually become visible. Usually Contractors are liable for these defects up to 5 to 10 years after the construction project is completed, and in some jurisdictions they’re even liable for ever. Would you like to be called back to repair a defect 5 years after the construction project has been completed? Of course not! But Contractors regularly hide defective construction work. Damaged pipes are covered over with ground. When the leak is eventually noticed the area could be covered by paving, or if it’s under the house then by concrete floor slabs, carpets and more. Repairing a simple cracked pipe could cost thousands when finished floors have to be ripped up inside someone’s house – compared to a few dollars if it’s fixed during construction. But sometimes the problem causes even more damage, think of a roof leak. Water from the roof could enter the house and damage ceilings, cupboards and even furniture. A simple construction defect can cost thousands to fix later. It also reflects poorly on the Contractor’s reputation. It’s therefore imperative that construction defects are repaired properly when they are first noticed so that they don’t cause a bigger problem later. Don't wait for the Architect or Engineer to notice the problem. Defects should be repaired as soon as possible while they’re still easily accessible. Waiting until the end of the project may result in other completed work being damaged when the defect is repaired, and access may be more difficult. In addition, the skills and the materials required to fix the problem may no longer be available on the construction project and they’ll have to be brought back to the project at additional cost. Quality problems must be fixed properlyIt’s sometimes tempting just to patch over poor quality construction work and quickly cover it up. But will the problem actually be fixed, or will it manifest itself later, maybe even after the project is completed. Next time you try and cover-up, patch, or hide poor-quality construction work and defects, consider the consequences of your action. The problem may very well come to bite you later, costing your company additional money and impacting your reputation. Rather take the time to do the task properly. Be proud of your completed work. Mistakes will happen, but make sure they are fixed properly so there aren’t problems in the future Other Useful articles: Does anyone give a …. anymore? The true costs of poor quality construction How we can improve quality in construction  This article is an extract from the book 'The Successful Construction Supervisor and Foreman'. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Would you like your hard work damaged by others? Would you like to redo your work because someone was careless and messed it up? Of course not! Yet, frequently completed work is damaged on construction projects. This results in additional work to repair the damage, which causes added costs, resources being diverted from other tasks, delays, and sometimes, even the client getting a product that’s flawed or has an imperfection, which results in problems later. Protecting completed work starts by instilling in your construction team, subcontractors and others working on the construction project, that it’s essential to take care of completed work. This can be discussed in inductions, team talks and briefings. It’s essential to speak out when careless workers are noticed. Everyone must respect the work of others. Of course it’s impossible to protect everything, but where possible surfaces that can easily be scratched or damaged should be covered by timber, cardboard and other materials. Some products arrive in plastic wrappings or are already taped, and these wrappings can be left in place where possible until the section is ready for handover. Fresh work that can easily be damaged, like newly painted surfaced, recently laid tiles and products that haven’t gained full strength, should be cordoned off. Set the standards from the start of the construction project. If people take care from the beginning, not just dropping stuff on the ground, bashing items, etc, then it’s instilled in their behaviour so they’re less likely to damage sensitive finishes later in the project. Other Useful articles: How important is quality on your project Repairing defective work on your construction project How we can improve quality in construction  This article is an extract from the book 'The Successful Construction Supervisor and Foreman'. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. In our previous article Construction Equipment Productivity we discussed how we can improve the productivity of construction equipment on our construction projects. We talked about selecting the right size machines, the importance of using skilled operators, balancing equipment that is working in teams and how one item can drag down the productivity of the other equipment working in the team, and then we discussed how faulty and old equipment can disrupt the project and impact productivity. In this article we discuss other ways to improve construction equipment productivity. Positioning Construction EquipmentThe loading times of the excavator is also impacted by the hardness of the ground. Soft ground is easily scooped up, while hard ground takes additional effort. A more powerful excavator will dig harder ground quicker. The position of the excavator relative to where it scoops the ground and to where it dumps it on the truck will impact the loading time. Every time the excavator must rotate from the scoop location to the load location involves time. The most efficient loading position is where the excavator can scoop ground and tip it straight into the truck. When the truck is parked behind the excavator then the excavator must continuously rotate through 180 degrees from the scoop to load position. Carefully consider where trucks will stand when they’re loaded, and how easily they can move in and out of that position. Correctly positioning the truck and planning the excavation operation could easily cut one or two minutes off every loading cycle, which could increase efficiencies by 20%, possibly even meaning the operation can be done with one less truck. Just think how much money can be saved in a day with one less truck. Servicing and Refuelling EquipmentAnother problem occurs when equipment has to be refuelled or serviced. Refuelling or servicing an excavator in the middle of a shift means that the machine must be stopped. Again this means that all the equipment working with the excavator stops. So 15 minutes stopping the excavator is usually 15 minutes when the other equipment doesn’t work. Servicing and refuelling key equipment, like excavators, after hours may result in additional cost for the service team, but it could result in better productivity. Just consider, I said in the previous article Construction Equipment Productivity that equipment might only work 7 hours in a day. So losing 15 minutes reduces productivity by another 4%. Other FactorsCompacting ground/soil requires water. If there’s insufficient water then the compaction will happen slower and all the equipment will operate less efficiently. We had a project where the client had to supply the water, but they couldn’t supply the required quantities and nor was the water available at the location specified in the contract. This not only reduced the productivity of our equipment, but it also delayed the project resulting in us lodging a claim for millions of dollars against our client. CranesBut, it’s not just about the productivity of earthmoving equipment. It includes planning the size of cranes, deciding the best position for the crane, carefully thinking how the crane will pick up materials and where they’ll be placed in position. Again using skilled operators will make the operations safer and faster. Cranes have their lifting cables running through reeve blocks. This allows the crane to lift a heavier load. If the lifting cable passes twice through the lifting block the crane cable is in effect doubled and can lift double the load of a single cable. The problem is that the crane cable must travel double the distance when lifting the load than if it was a single cable, so it slows the lifting operation, which is not normally a problem when lifting a heavy load. Sometimes the crane lifting cable passes through the lifting reeve blocks several times and there’s 4 or 6 lifting lines connecting the crane hook to the crane. This is required when lifting heavy loads and it’s essential when loads must be precisely fitted into position and slow manoeuvring is required. But, it slows the lifting of repetitive and light items. Changing the number of reeves or lifting loops connecting the crane to the lifting hook can dramatically increase the speed the crane lifts objects – of course this should be done with the permission of the crane operator or an expert that understands the lifting capacity of the crane’s lifting cable and it will have to be changed back for heavy loads. Good Planning and InstructionsOften moving equipment from one location and setting it up in another location is time consuming and results in zero production in that time. Planning these moves so that they happen quickly will improve productivity. So always ensure that the work areas are ready and clear of obstructions ahead of the time. Give operators clear instructions as to what must be done and the best position for the equipment to maximise productivity. Improving Productivity of Construction EquipmentEquipment used badly can be dangerous and expensive, but the right item used by a good operator makes construction easy and efficient. Often construction equipment on projects is unproductive, machines stand idle and equipment is not used efficiently. Equipment costs can make up a large portion of the costs on a construction project - particularly earthmoving and road projects where equipment costs could account for 30 to 50% of the costs. So even improving productivity by 5% could add an extra 2.5% of profits. But improved equipment productivity brings other benefits, such as operators are more productive, less fuel is consumed by the machines, the project can be completed sooner, and other operations become more efficient and productive. It is worth spending the time to analyse how the construction equipment is being used on your construction equipment. See how productivity can be improved. Often it takes only a few small adjustments to make significant improvements. Other Useful articles: Construction productivity How to improve construction productivity Is your construction project losing money? Do you want to find out why?  This article is an extract from the book 'The Successful Construction Supervisor and Foreman'. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. In our last article Is overtime crushing your construction project? we discussed the cost of working overtime in construction. Often construction managers get into the habit of working extended hours, which adds to the cost of construction, and causes other problems, including accidents and family issues. As we stated though, some workers also get into the habit of relying on extra pay earned from working overtime. Overall working overtime should be discouraged as the costs often far outweigh any benefits to the project. Careful planning and employing a few extra resources can often eliminate the need to work overtime on your construction project. However, we all know that sometimes working extra and extended shifts on construction projects is unavoidable. Even the most well planned construction project can get into trouble and need additional time. Some tasks may have to be done afterhours when the project or the area is less congested. In fact, a few extra hours working a critical trade could make a big difference to the project's overall schedule The golden rules for working overtimeWhen it is necessary for work to happen after hours on your construction project you can ensure that workers are productive, costs are kept to the minimum, that work is done safely, and that the required tasks are completed by following a few simple rules.

ConclusionProjects should not get in the habit of working overtime. Controlled and limited overtime work can sometimes be beneficial. Always consider whether employing extra resources would be a more cost effective solution to working extended hours. Other useful articles Will your construction project be 100% complete when it's finished? Are you employing the right people on your construction project? How much is your brand worth? Why a good brand is vital for construction companies. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. © 2021 This article is not to be reproduced for commercial purposes without written permission from the author. Costs of construction overtimePeople working overtime are usually paid 50%, or even double their normal rates. Are they 50 to a 100% more productive? Definitely not. In fact they’re probably less productive. Manual work is physically exhausting. Even operating a machine for extended hours is tiring. I found that production after working 9 hours fell dramatically. Working an extra hour possibly only yielded an additional half hour’s production. In effect the company is paying an hour for half and hour’s work – or double time. Add the premium for overtime and it becomes a very expensive additional half hour’s work. But overtime can become even more expensive. Often overtime isn’t controlled properly. So people say they’ve worked the extra hours (and are paid the time) but they haven’t. Workers are often not supervised properly after hours, workers slack off, or they’re left waiting for instruction, so productivity is lower. Sometimes key workers, perhaps like a crane operator, aren’t there, which means that other workers can’t operate effectively. When equipment breaks down afterhours there often isn’t anyone available to repair the items, and without the item the team can’t work properly. Problem of working excessive hours on construction projectsSometimes workers enjoy working overtime to earn the additional overtime rates. But, to compensate they may take another day as a rest day, so they work the same hours, but some hours are paid at the higher overtime rate. On the days when they’re absent it impacts the efficiencies of their team – especially if they’re a critical component. Working excessive overtime can lead to tiredness and result in mistakes and even accidents. The right balance on construction projectsUnfortunately some projects get into a routine of working overtime. Those are the hours that were worked on the last project, or those are the hours that were instituted at the start of the project. In fact, some workers become used to earning the additional wages earned from working overtime so they even object when the overtime hours are cut. Often employing a couple of extra people and hiring additional equipment will negate the need to work overtime and it will be cheaper than working the additional hours. Sometimes overtime is essential to catch up lost time, or to complete a critical task, but it might not be required that the whole project works extra hours. Check who should work overtime, ensure only those workers stay longer. Then ensure that they will have all the necessary support services and supervision so that they can work efficiently and safely. Other useful articles planning your construction project labour productivity on construction sites Will your construction project be completed on schedule? Read this  This article is an extract from the book 'The Successful Construction Supervisor and Foreman'. Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Winter is usually considered the off-season for construction, but a savvy crew can still complete plenty of work when the temperature drops. Working in cold weather presents its own challenges. What are the most common construction safety issues, and what can you do to prevent or mitigate them? Dealing With Snow and IceOne of the most obvious hazards of construction work in winter is the accumulation of snow and ice. In addition to being cold, this buildup can create traction issues and slip-and-fall accidents for both team members and equipment. Before each day, take the time to inspect the job site. Be on the lookout for snow or ice buildup. Footpaths and areas that get a lot of traffic — pedestrian or otherwise — should be covered with salt or kitty litter to provide traction and melt the ice. Excessive ice buildup should be chipped away or otherwise removed to prevent it from causing bigger issues in the future. Protecting Construction Equipment From Cold WeatherHuman crew members aren’t the only ones at risk in cold temperatures. You’ll also need to take steps to protect your construction equipment, especially if you don’t normally operate during the winter months. Start by carrying out some winter-centric maintenance — double-checking things like tire inflation and fluid levels. Ensure your antifreeze is up to the task, especially if you’ve been topping off the radiator with water during the summer. If you’re not sure, or you don’t have a hydrometer on hand to test, flushing and refilling the cooling system is your best option. Pouring Concrete in Cold TemperaturesCool and dry weather isn’t necessarily a bad thing for curing concrete, but once you drop below a certain temperature, it can prevent it from hardening to its full strength. If you’re pouring concrete in the depths of winter, look into tools for keeping your pour warm and dry while you wait for it to cure. Concrete blankets can be incredibly affordable and can let you keep working through the season. Keeping Your Construction Crew SafeHumans can adapt to most environments, but we need tools to protect us from the elements. Frostbite and exposure to the elements are major concerns for teams working in cold weather. Ensure that everyone is property attired before they come onto the job site in the morning. Provide them with heated tents or offices where they can get out of the elements for breaks or lunches, and encourage your team to take frequent breaks throughout the day. Staying Warm in WinterWintertime doesn't have to cause projects to grind to a halt. You just need to make sure everyone is ready to work outdoors when the temperature starts to drop. Maintenance, preparation and a few extra tools can make all the difference, especially if you live or work in an area that’s prone to extreme cold during the winter. Construction can continue and deadlines can be met despite the challenges of the season. Author Bio: Rose Morrison is a freelance writer who covers construction and building design topics. She is also the managing editor for Renovated. Other Useful Articles How To Select The Appropriate Construction Method To Increase Safety And Efficiency Top Safety Concerns on Construction Sites - And How to Avoid Them Construction projects and high temperatures - do you know the risks? Why Safety Is Important On Your Construction Project Do you want to learn how to manage construction projects successfully?Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. COVID-19 has caused havoc in the construction industryBuilders need to change the way they operate and manage construction projects to secure their long-term success. With coronavirus cases on the rise again in the UK, America, Europe and many other countries, certain restrictions have been reintroduced across nations. The construction industry will continue to operate, but now more than ever standards of health and safety need to be enforced to reduce the rate and risk of infection. The question that contractors are facing is how to balance keeping their workforce healthy while continuing to operate to maintain economic security. As more research is conducted into covid-19, authorities have published advice calling for work to resume as long as all recommended precautions can be enforced. Read on to learn more builders’ guidelines for work in the time of COVID-19. Get everyone in your construction team involvedEmployee education and communication are essential tools for fighting this viral pandemic. Your construction teams should be kept updated about the latest COVID-19 facts, including how the germs can be spread. The rationale behind protocols and how they could help prevent covid-19 infection should be clearly explained and repeated regularly to keep facts fresh in employees’ minds. Posters with the same details should be posted in portable toilets and common areas for the same reason. Specific time slots within working hours should be allocated for these information sessions. If workers are concerned that the time spent learning about the virus will be docked from their wages they might not take in or understand the information they’re presented with. Keeping your construction crews in the loop will have the added benefit of maintaining a sense of community and camaraderie. Each worker will feel they’re part of a team and be more likely to voice concerns and let their supervisors know about potential problems. If there’s a feeling that everyone is in this together, someone who feels ill won’t be worried about losing their job and will inform their co-workers immediately – lessening the chance of an outbreak among staff. Don't forget to include all your subcontractors, they are vital to the success of your construction project and keeping it covid-19 safe. Follow covid-19 guidelinesWhile the advised measures from the United Kingdom’s government don’t quite stretch to modular walk-through anti-virus stations, they’re impressively thorough and comprehensive. The Department for Business, Energy and Industrial Strategy issued specific regulations for construction and other outdoor work, and the Construction Leadership Council (CLC) has published its own suggestions. They’re presented here, along with various additional measures that many operators in the United Kingdom have decided to adopt. ● The guidelines stipulate that anyone who feels ill, has a temperature or is coughing should either stay home or go home as soon as these symptoms develop. ● Face coverings should be worn over the nose and mouth on public transport and in enclosed spaces. At the same time, touching the face, eyes, nose and mouth should be avoided wherever possible. ● When eating, workers should wash their hands after removing their face coverings but before touching their food. Food and drink shouldn’t be shared with anyone during this time. ● Similarly, implementing a “no handshake” policy is a good idea. Soap, running water and disposable hand towels should be provided at several strategic locations on building sites. ● Anyone arriving on a site ought to be given hand sanitiser. Used tissues should be thrown into a rubbish bin that’s been designated for that specific purpose. ● While temperature screenings are not mandatory, several companies are enforcing them. ● Appropriate social distancing (at least 1 metre and preferably 2 metres between each person) must be maintained. As an added precaution, some construction companies have begun disinfecting high-touch, shared areas on a daily basis. Such areas include scaffolding, breakrooms, shared tools, crew vehicles’ steering wheels, gear sticks and door handles and bathroom facilities. Shifts should be staggered between different tradespeople and even different groups of the same type of workers to prevent large gatherings on your construction project. Meeting size should be restricted, and weather permitting, held in the open air whenever possible. Individuals who are especially at risk of infection, such as those with diabetes or other chronic diseases, should work from home if they can. Video calls should replace site inspections and face-to-face appointments unless in-person meetings are absolutely essential. This includes home visits and discussions with clients; email, telephone calls and video communications or even text messages are strongly recommended. Plan Ahead for Project Changes It’s important to remember that the fallout from COVID-19 will be huge and to expect and plan for this on your construction project wherever possible. Projects will take longer to complete as staff education, sanitising procedures, absences due to self-isolation and team staggering all eat into building schedules. Additionally, masks, hand sanitiser, posters and other educational equipment all cost extra funds that could drain resources. That’s before the impact of smaller meetings and reduced face-to-face contact have even been considered. Every decision will be delayed slightly because discussions won’t be able to flow as freely with as many people, which could ramp up costs and timeframes considerably. Additionally, some instances cannot be planned for – such as subcontractors not being properly educated on the virus and thus transmitting the disease to an otherwise COVID-free building site. Adjust Project Parameters Every construction project is unique, and the required health and safety measures will differ from job to job. The requirements for fitting doors and windows won’t be the same as those needed for a full-scale house build or roadworks. The best course of action employers and workers can take would be to evaluate their specific construction projects and then enforce and maintain all possible precautions. Reviewing the situation regularly as your construction project develops, additional restrictions are imposed or new information about COVID-19 is learned, is also an excellent idea. The pandemic will cause financial losses and it will take time for the global economy to recover. But overwhelming as it might feel, everyone is in the same situation. The only real option is to work together to weather the storm. There’s never been a more appropriate time to stick to the good old British motto: Keep calm and carry on! Author Bio: With a background in project management and a love for writing, Mara Sampson is an editor for Build World, the UK’s top builder’s merchant and build material supplier. Other useful articles: Force Majeure In Construction Contracts: Tips And Traps Prepare your construction project for covid-19 lockdown What will you do if you are quarantined? Who is responsible for safety on your construction project? Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. 10 Questions to ask that will make you a better Contractor

Take a little extra time to ask these questions and your projects will be completed safely, with good quality, more productively and quicker. Other Useful Construction ArticlesHow to improve cash flow on your construction projects - Part 1 Who is responsible for safety on your construction project? Who is responsible for quality on your construction project? The 10 P’s of successful construction project management Are you working for free on your construction project? Do you want to learn how to manage construction projects successfullyPaul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. © 2020 This article is not to be reproduced for commercial purposes without written permission from the author.