"Installing solar power can benefit your company in many ways" In today’s environmentally conscious world, businesses are increasingly seeking ways to reduce their carbon footprint and operational costs. One effective solution is installing a commercial solar system. This innovative approach not only aligns with sustainable practices but also offers numerous financial and operational benefits. In this blog, we will explore what a commercial solar system is, its benefits, and how it can be used for industrial or commercial purposes. Additionally, we’ll highlight ten key advantages of adopting this technology. What is a Solar System for Commercial Purpose?A commercial solar system is designed to meet the energy needs of businesses and industrial facilities. Unlike residential solar systems, which cater to individual homes, commercial solar systems are larger and can generate more power. They typically include solar panels, inverters, and mounting systems installed on rooftops or ground-mounted arrays to convert sunlight into electricity. This electricity can then be used to power various business operations, reducing dependence on traditional energy sources. What are the Benefits of a Solar System?The benefits of a solar system, particularly a commercial solar system, are numerous: 1. Cost Savings: One of the most significant advantages is the reduction in electricity bills. By generating your own power, you can drastically cut down on energy costs. 2. Environmental Impact: Solar energy is a clean and renewable source, helping businesses reduce their carbon footprint and contribute to a sustainable future. 3. Energy Independence: With a commercial solar system, businesses can become less reliant on the grid and protect themselves against fluctuating energy prices. 4. Increased Property Value: Installing solar panels can increase the value of your commercial property. 5. Tax Benefits and Incentives: Many governments offer tax credits, rebates, and incentives for businesses that install solar systems, further reducing the overall cost. "Make use of unused space to add value to your company." What is the Commercial Use of Solar Power?Solar power can be used in a variety of ways for commercial purposes:

"Adding solar to your farm will reduce energy bills." How is Solar Energy Used for Industrial or Commercial Purposes?Solar energy is utilized in industrial and commercial settings through:

10 Key Advantages of Commercial Solar Systems

ConclusionIn conclusion, installing a commercial solar system offers a plethora of benefits, from cost savings to environmental impact and beyond. By harnessing the power of the sun, businesses can not only enhance their operational efficiency but also contribute to a sustainable future. If you’re looking to make a positive change for your business and the environment, a commercial solar system is an excellent investment. The Benefits of Green Building - Environmentally Sustainable Buildings AuthorArticle supplied by Mark Wilson for commercial solar, energy upgrades and solar battery storage This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?Paul Netscher has written several easy-to-read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. We will not enter into discussion on why a particular comment was removed.

0 Comments

"All this material will be carted to the waste dump at great cost including cartage and dump fees. Good timber and other building material trashed - what a waste!" Construction work creates a considerable amount of waste. From clearing the site to the final finishing of the building, waste is generated through every phase of construction. If the waste is not adequately managed, it may create a big problem for the entire environment, including human health, as well as resulting in large costs to dispose of the waste. Proper and efficient waste management is as essential as the construction itself. The green and sustainable construction industry also urges production waste to be as low as possible. Reducing, Recycling, and reusing the waste can help efficiently manage and reduce construction waste. Sometimes, construction waste is unethically disposed of in the water streams without concern for human health. In contrast, the construction waste generated in the U.S. is meant to be disposed of in landfills planned and controlled by the Code of Federal Regulations (CFR) 40 with the labels D and C. There are several ways to properly manage the construction waste generated by the development process or after the demolition. This article discusses a correct way of waste management that might help you in your next construction project. Reduce Construction WasteWhen working on a construction project, reducing waste material may help you in on-time and proper management. Increase profits - reduce material wastage on construction projects Some Recyclable and reusable alternative materials used in construction may also help reduce waste. Recyclable materials are then reused in the construction of the new building will also reduce waste and save natural resources. The selection of modular metal forms in concrete construction might be helpful in many ways. It allows the building to be demolished quickly and reuse the material in other projects. Similarly, the wood waste generated by the framework made of plywood and lumber can be reduced. On the other hand, the latest construction methods can help in preventing construction material waste. The reduction of waste dramatically helps in reducing the harmful impact on human and environmental health. "Ordering the most suitable lengths can limit the offcuts and waste of construction materials. Remember the contractor pays for material that is not used., plus the costs to dump it" Reusing Construction MaterialsConstruction and demolition of the building and infrastructure are very common processes. After the demolition of the building, the debris is usually thrown away. But if the recyclable material is used in the construction, that can be reused in other construction. In contrast, proper removal of doors, windows, and other accessories can be resale and reused in other construction. Many alternative materials can be used in place of conventional ones. These alternative materials are reusable. If the building is constructed with these materials, the debris will be reused in other construction after demolition. In contrast, non-reusable waste is reused in landfills. "Some salvaged items can be reused or sold. Even giving some stuff for free will save you the cost of disposing of the items, and it's good for the environment." Recycling of Construction WasteWhen the construction waste is converted into debris, it can sometimes be recycled. For example, rubble and concrete are recycled to make aggregates. The common methods of Recycling are: Site-separated: The systematic management of the waste on the site is necessary. Try to separate the waste by type on-site and deal with it hand-to-hand. It is a super helpful method to manage the more considerable waste on-site, even in less time. However, the method needs little extra space and active supervision. Mixed Recycling: This method does not need to separate the waste by type. Instead, you can use a single container and mix all the waste. This method is helpful if there is little space on-site. Hybrid Recycling: this is the combination of the two methods mentioned above. It is the most recommended one if you can manage the site extra efficiently. Choosing the suitable method of waste management on site depends on the resources, timeline, and amount of waste. Before starting the demolition or construction on-site, develop a waste management plan considering all the factors. Construction Debris Waste or Sustainable Commodity? Of course, all this won't work unless your employees and subcontractors understand how the project's recycling system works, and they also understand that recycling reduces waste that goes to the dump which will reduce costs and benefit the environment. Good signage at the waste collection points is important. What’s expected of your subcontractors? Do they know? "No attempt to sort and recycle on this construction project! It's going to cost lots of money to take it to the dump." Simple Steps to Help the Environment and Improve ProfitsConstruction waste generation is a big problem in the industry, whereas the proper management of waste is a little challenging. Construction waste comes from the demolition and development process and even from heavy equipment like construction cranes for sale. The waste is usually disposed of in water streams, which is unethical and creates many problems for humans and the environment. However, there are some alternative methods to reduce the burden of construction waste. Three basic approaches, such as reducing, reusing, and recycling the waste, can help greatly in minimizing the waste. The article has some basic guidelines for managing construction waste. The economic benefits of being environmentally friendly AuthorIf you are looking for quality used construction equipment to better manage your construction project, visit us at MY- Equipment. We are a Houston-based used equipment dealership that stocks heavy machinery from the leading brands. This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?"This book helps with practical tips learned from real experiences. A must read book for the people who are involved in construction projects, especially project managers." Paul Netscher has written several easy-to-read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. We will not enter into discussion on why a particular comment was removed.

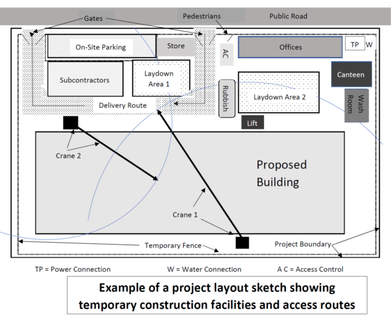

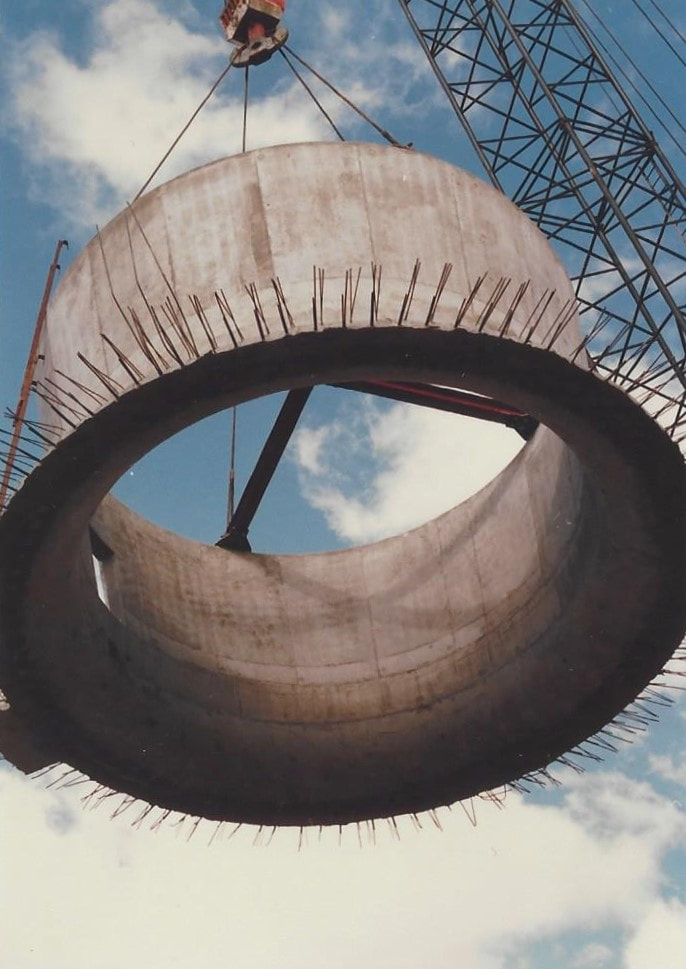

"Poor storage of construction materials can result in the materials being damaged or stolen." Ensuring the safety and integrity of the construction materials needed to complete a build is a huge priority. After all, securely storing construction materials is a logistical necessity and crucial to project success! From safeguarding against theft to protecting against environmental factors, not properly protecting your construction materials can significantly impact project timelines, quality and budgets! Assessing storage needsAssessing storage needs is the first step in securely storing construction materials. It involves carefully evaluating the types and quantities of items to be put away, considering factors like holding duration and environmental conditions. For instance, perishable materials like cement require different holding conditions than durable materials like steel beams. Are your construction materials compliant? Understanding these needs can help you determine the appropriate solutions and minimize risks such as damage or theft. Likewise, assessing your holding needs helps optimize space utilization and ensures efficient requisite management throughout the project. "A disorganised storage area is dangerous, materials could be damaged, and finding materials is difficult and wastes time." Choosing the right storage locationAnother necessity for correctly storing materials is selecting the right holding location. Opting for secure, well-lit areas with limited access points ensures better protection against theft and vandalism. Consider the proximity to the construction site to enhance convenience and efficiency in transportation. For example, choosing a location closer to the project site reduces the time and costs of frequent requisite retrieval. In the end, a strategically chosen location can also minimize the risks of damage from environmental factors such as weather or temperature fluctuations. Construction project logistics - the hidden bottleneck that could be strangling production "Before starting your project plan where your offices and storage areas will be located. Ensure that storage and laydown areas for heavy materials are accessible to the project's cranes." Implementing inventory management systemsImplementing inventory management systems is beneficial for safely storing construction materials, too. By maintaining a detailed inventory, you can efficiently track requisite usage and detect any discrepancies. Utilizing technologies like barcode or RFID further enhances the accuracy and efficiency of inventory management. Regularly updating inventory records allows for better control over material flow and reduces the risk of shortages or overstocking. Still, just communicate your requirements to all your employees properly! With clear communication and consistent adherence to inventory protocols, you can streamline the handling processes and minimize the likelihood of errors or delays. Furthermore, implementing inventory management systems promotes accountability among staff members, ensuring everyone is responsible for maintaining accurate records and following established procedures. Securing the storage areaSecuring the storage area is necessary for protecting your requisites from theft and damage. Installing security measures like surveillance cameras and alarms enhances the site's safety. Additionally, consider employing security personnel or guard dogs for added protection against intruders. Implementing access control systems with key cards or biometric authentication ensures that only authorized personnel can access the area. Finally, regular inspections and maintenance of security equipment, such as locks and fences, are required to promptly detect and address any vulnerabilities. "Theft of construction materials results in additional costs, but worse missing materials will delay the project. Security measures will help prevent theft." Protecting against the weatherProtecting against the weather is needed to ensure the longevity and quality of construction requisites. After all, shielding them from adverse weather conditions, such as rain or extreme temperatures, helps prevent damage and deterioration. Thankfully, tarps or weatherproof covers protect items outdoors from moisture and UV exposure. Still, it's also important to keep sensitive materials like wood away from moisture to prevent rotting and warping. In addition, storing metal items indoors or under shelter helps prevent rusting and corrosion, prolonging their lifespan. Safely stacking and moving construction materialsMaterials should be stacked in such a way that they can easily be retrieved when required and so that there is no danger of stacked material falling over and crushing workers. Preferably material storage areas should be level areas. When large materials are moved by cranes the material must be secured so it can't move in transit, and cranes and forklifts must not be overloaded or become unbalanced. For more read Handling construction materials Collaborating with suppliers and contractorsCollaborating with suppliers and contractors can be beneficial for effective construction material storage. Communication with suppliers ensures timely delivery and coordination of storage arrangements. Establishing clear guidelines for material handling and storage responsibilities further fosters efficiency and accountability. Ordering the correct quantity of construction materials By partnering with suppliers, just-in-time deliveries can be arranged to minimize on-site holding needs and reduce costs. Similarly, coordinating with contractors ensures alignment between project timelines and material requirements. This collaborative approach facilitates smoother logistics and reduces the risk of shortages or delays. planning deliveries to construction sites Effective collaboration with suppliers and contractors also extends to tasks such as moving construction materials to storage and hiring movers for the job. In such instances, it's important to clearly communicate your storage needs while respecting the expertise of those you're working with, ensuring that you assist without stepping on toes. By clearly outlining your requirements and expectations, you can facilitate smooth coordination and minimize the risk of misunderstandings or disruptions. Whether coordinating delivery schedules or arranging for professional movers, maintaining open lines of communication fosters a collaborative environment conducive to efficient storage management. "Materials lying on site take up space, and usually suppliers must be paid when the materials arrive while the contractor only gets paid when the materials are fixed in place." Legal and regulatory complianceLegal and regulatory compliance is a big priority regarding construction material holding. Familiarizing yourself with local regulations and building codes ensures adherence to safety standards and zoning laws. Permits for temporary holding structures or hazardous materials are also required to avoid legal complications. Finally, note that compliance with regulations mitigates the risk of fines or penalties and helps maintain a safe working environment! don't let fire destroy your construction project The importance of securely storing construction materialsAfter everything we covered on securely storing construction materials, proactive measures are key to safeguarding project assets. By implementing robust security protocols, collaborating with stakeholders, and staying abreast of legal requirements, construction companies can minimize risks and ensure the integrity of their materials. After all, implementing these practices isn't just about protection; it's all about setting the foundation for successful project execution and client satisfaction! Do Your Material Deliveries Suck? How to avoid problems AuthorEvangeline Thorndike is a reliable figure in the construction industry, known for her team leader and manager expertise. With over a decade of experience, she has successfully overseen numerous projects, ensuring efficient material management and adherence to safety protocols. This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?"It's a very good book. I recommend it and Paul's articles too for junior project managers, and defiantly it will add value and experience to readers." Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. We will not enter into discussion on why a particular comment was removed.

"Construction equipment is often an essential component in construction projects. Working in a foreign country often presents additional challenges to find the right equipment." Frequently construction companies have to move construction equipment from one country to another country. This might be because the contractor is working on a construction project in another country. Or perhaps they have completed a project in another country and want to bring the equipment back to their home base. Sometimes, contractors purchase equipment in another country for a project in their home country. Maybe the equipment was not available in their country, or it was cheaper to procure the item in that other country. This equipment could be new construction equipment to do construction work (such as excavators, bulldozers, cranes, etc), it could be used (second hand) construction equipment, or it could be equipment and machinery which is required to be incorporated into the project forming an integral part of the completed project. The construction equipment could be purchased or hired equipment, although transporting hired equipment to another country will require permission and help from the supplier. Become Great at Hiring Equipment for Your Construction Project Navigating the logistics of overseas construction equipment transport presents many unique challenges. So, you must be as thorough in your preparation as possible, or you’ll face obstructions and budgeting difficulties even before your projects start! Preparing for construction equipment transportPreparing construction equipment for transport contributes significantly to safe and successful relocation. Before moving heavy machinery, a thorough inspection is necessary to identify potential issues or damages. Cleaning the equipment and securing loose parts helps prevent accidents during transport. Likewise, you must protect vulnerable components from damage using appropriate padding and coverings. Properly preparing equipment minimizes the risk of breakdowns or malfunctions during transit, ultimately saving time and money! Choosing the right transport methodChoosing the right transport method for moving heavy construction equipment offers timely and cost-effective delivery. Factors such as the size and weight of the equipment, as well as the destination, must be carefully considered. For example, shipping containers are ideal for smaller equipment and protect from the elements. Flat racks are suitable for oversized or irregularly shaped equipment, offering flexibility in loading and unloading. Finally, roll-on/roll-off (RoRo) is a convenient option for wheeled equipment like bulldozers and loaders, allowing for easy drive-on and drive-off. Cranes, lifting equipment and slings "Moving large pieces of equipment to construction projects may require special movers and cranes. Check the specialist equipment is available when and where it's required." Understanding shipping regulations and documentationYou must brush up on your shipping regulations and documentation for overseas equipment transport. After all, international shipping involves compliance with various laws and regulations governing import/export procedures. That includes obtaining the necessary permits and adhering to customs requirements. Documentation such as bills of lading, commercial invoices, and packing lists must also be accurately prepared and submitted. (A Guide to Construction Equipment Attachments) Failure to comply with shipping regulations can result in delays, fines, or even seizure of the equipment! Of course, partnering with experienced logistics providers can also help navigate the complexities of shipping regulations more effectively. Risk management and insuranceRisk management and insurance should always be part of transporting heavy construction equipment overseas. Construction companies must assess and mitigate potential risks associated with the process, such as damage, loss, or delays! Comprehensive insurance coverage provides financial protection against unforeseen events during transit. Strategies for risk management include proper packaging, securing equipment, and choosing reliable transport methods. In addition, effective communication with insurance providers certifies clarity regarding coverage and claim procedures. "Accidents can occur when moving construction equipment." Partnering with reliable logistics providersPartnering with reliable logistics providers naturally helps achieve smooth and efficient overseas equipment transport. Construction companies should prioritize selecting experienced and reputable logistics partners who specialize in handling heavy machinery. Construction companies can benefit from their expertise in navigating complex shipping regulations and documentation requirements by choosing a trusted logistics provider. Similarly, reliable logistics partners offer comprehensive services, including proper packaging, secure loading, and timely delivery. Finally, collaborating closely with logistics providers fosters clear communication channels, allowing seamless coordination throughout the transport process! Allowing for all the costs of transporting your equipmentBudgeting and cost considerations are major aspects of overseas construction equipment transport planning. Construction companies must carefully assess expenses, including shipping fees, insurance premiums, and customs duties. Budgeting effectively allows companies to allocate resources appropriately and avoid unexpected financial strain. Similarly, negotiating rates with shipping companies and logistics providers can help minimize costs. Also, considering equipment size and destination distance allows for better cost estimation. Finally, accounting for potential unforeseen expenses is important to prevent budget overruns! If you plan to return the machine back to your home country remember to take into account these costs as well. "The actual transport costs is often only part of the total costs that are incurred when moving construction equipment to another country." Ensuring timely delivery of the construction equipmentTimely delivery is a main priority when transporting overseas construction equipment. After all, construction companies must meticulously plan schedules and coordinate logistics to meet project deadlines. Companies can minimize the risk of setbacks by proactively addressing potential delays and implementing efficient transport methods. Consequently, monitoring transit progress and promptly addressing any issues helps maintain momentum toward timely delivery. Utilizing tracking technologies and real-time updates further enhances visibility and allows quick adjustments if needed! Don't make these scheduling (programming) mistakes Dealing with customs clearance and border issues"Without the proper paperwork equipment could be stuck in ports. Customs paperwork is often long and tedious and must be completed meticulously." Dealing with customs clearance and border issues is another important aspect of overseas construction equipment transportation. Construction companies are forced to navigate complex import/export regulations and documentation requirements. Effective communication with customs officials and brokers facilitates clearance and minimizes delays. Of course, anticipate potential border issues and have contingency plans to address them promptly, just in case! Environmental considerations and sustainabilityEnvironmental considerations and sustainability are increasingly important factors in overseas construction equipment relocation. Construction companies must address the environmental impact of their operations, including carbon emissions and waste generation. Implementing eco-friendly transport initiatives and technologies helps reduce the carbon footprint associated with this process. Moreover, sustainable practices such as recycling and reusing materials contribute to environmental conservation efforts. Managing construction projects in extreme weather conditions also requires careful planning and adaptation strategies to minimize the environmental impacts of climate control and similar measures to counter heat or cold. Post-delivery inspection and maintenancePost-delivery inspection and maintenance help maintain the longevity and performance of construction equipment following overseas transport. Construction companies must conduct thorough inspections upon machine arrival to identify any damages or issues that may have occurred during transit. Promptly addressing any damages or issues through maintenance and repairs helps prevent further deterioration and guarantee optimal functionality. Furthermore, implementing regular maintenance schedules helps prolong the lifespan of your crucial tools and minimizes the risk of breakdowns during operation! When construction equipment arrives on your project check these things. "Check all construction equipment carefully when it arrives on the project site." Make transporting construction equipment cross-border easyMastering the logistics of overseas construction equipment transport will ensure the smooth execution of projects on a global scale. Construction companies can optimize their operations and achieve success by understanding the intricacies of the process. Besides, with careful planning and proactive management, this daunting task becomes much easier! The impact of poor equipment productivity on construction projects AuthorMeet Elara Nightly, a seasoned logistics and moving specialist collaborating with Interstate Relocation, a company dedicated to helping people with residential or commercial international relocations quickly and easily. With a passion for streamlining international relocations, Elara has dedicated her career to helping individuals and businesses navigate the complexities of moving overseas. This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?"The book is really great. It perfectly fills majority of PM theoretical books with practical experience of real professional. I like this type of material because its not just an interesting reading (it really is) but it is a kind of methodology." Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. We will not enter into discussion on why a particular comment was removed.

"Moving construction equipment requires planning so it is done safely." Moving construction equipment can be complicated, requiring careful planning and execution to guarantee both the safety of personnel and the protection of valuable machinery. Whether you're relocating equipment within a construction site or transporting it to a new location, proper procedures are essential to prevent accidents and damage. Follow some top tips for moving heavy construction equipment safely. Moving heavy construction equipment safely Before moving any construction equipment, it's crucial to assess the potential risks and hazards associated with the task. Identify obstacles, such as uneven terrain, overhead obstacles, or narrow passages, that could pose challenges during the move. Evaluate environmental factors, like weather conditions, that may impact safety. By conducting a comprehensive risk assessment, you can develop strategies to mitigate potential dangers and guarantee a smooth moving process for your construction equipment. "Identify obstacles which could derail moving your construction equipment." Use the right equipment and accessoriesSelecting the appropriate equipment and accessories is crucial for safe transport when moving heavy construction equipment. Utilize heavy-duty trailers, trucks, or cranes capable of supporting the weight and size of the machinery being moved. Use quality straps, chains, or slings to secure the construction equipment firmly during transit, reducing the risk of shifting or tipping. Also, do not neglect the importance of having a first aid kit at all times on a construction site, and consider using specialized attachments or lifting devices designed for specific types of construction equipment for secure handling. Cranes, lifting equipment and slings "Accidents can cause injury and damage equipment." Inspect construction equipment and ensure proper maintenanceInspect the construction equipment to be moved thoroughly, checking for any signs of damage or mechanical issues that could compromise safety. Check that all safety features, such as brakes, lights, and warning signals, function correctly. Before initiating the move, perform any necessary maintenance or repairs to prevent breakdowns or accidents en route. It's advisable to keep detailed records of maintenance activities and inspections for compliance purposes and to facilitate future servicing needs, contributing to the overall safety and reliability of the equipment. Preventive Maintenance Checklist for Construction Equipment Train personnel and establish clear communicationMake sure that personnel involved in moving construction equipment are adequately trained in equipment operation and safety procedures. Provide instruction on proper lifting techniques, load securement, and signaling protocols to minimize the risk of accidents. Establish clear communication channels, including hand signals or two-way radios, to coordinate movements effectively and alert team members to potential hazards. Conducting regular safety drills and refresher training sessions helps reinforce knowledge and skills, fostering a culture of safety awareness and proactive risk mitigation among the construction and transport teams. "Ensure that personnel involved in the moving process are adequately trained in equipment operation and safety procedures." Plan the route and prepare the construction work siteBefore moving heavy construction equipment, plan the route carefully to avoid obstacles, steep inclines, or congested areas that could impede progress. Clear the path of debris, obstacles, or overhead hazards that could pose risks during transport. Consider factors such as overhead clearance - particularly electrical cables, weight restrictions, and road conditions when selecting the route. If necessary, coordinate with local authorities to obtain permits or escorts for oversized loads. In addition, communicating with relevant stakeholders, such as utility companies or local communities, can provide valuable insights into potential road closures or construction projects that may affect the chosen route, warranting smoother transit and minimizing disruptions. Secure permits and adhere to regulations when moving large or heavy construction itemsDepending on the size and weight of the construction equipment being moved, you may need to obtain permits or comply with regulatory requirements governing oversized or overweight loads. Research and adhere to local, state, and federal regulations regarding equipment transport, including licensing, signage, and escort requirements. Failing to obtain the necessary permits or comply with regulations could result in fines, delays, or legal consequences. "Failing to obtain the necessary permits or comply with regulations could result in fines and delays," Monitor weather conditions on the construction project and routeKeep a close eye on weather forecasts leading up to and during the construction equipment move, as adverse weather conditions can significantly impact safety. Avoid transporting equipment during severe weather events such as high winds, heavy rain, or snowstorms, which can affect visibility and road conditions. If inclement weather is forecast, consider postponing the move until conditions improve to minimize risks. It's also wise to have contingency plans for unexpected weather changes, such as alternative routes or secure storage options for the safety of personnel and equipment. Implement safety precautions during loading and unloadingLoading and unloading heavy construction equipment requires careful planning and execution to prevent accidents or damage. Use appropriate ramps, loading docks, or lifting devices to facilitate safe loading and unloading operations. Make certain that personnel are clear of the equipment's path during these procedures and use spotters to guide the process and prevent collisions or accidents. Likewise, conducting pre-loading safety checks to confirm the stability of the equipment and its load distribution further enhances safety measures, minimizing the risk of accidents or incidents during the loading and unloading process. 5 Construction Safety Tips When Working Around Heavy Machinery "Loading and unloading heavy construction equipment requires careful planning and execution to prevent accidents or damage." Perform regular safety inspections during transitPeriodically inspect the equipment and secure mechanisms during transit so everything remains in good condition. Check for signs of shifting, loosening, or damage to straps, chains, or attachments, and address any issues promptly. Monitor the equipment's stability and adjust load distribution if necessary to maintain balance and prevent tipping. It's also important to document these inspections for record-keeping purposes and to track any recurring issues that may require further attention. Regular maintenance and monitoring contribute to the overall longevity and reliability of the equipment, enhancing operational efficiency and safety standards. Have a contingency planDespite careful planning and precautions, unforeseen circumstances may arise during construction equipment transport. Develop a contingency plan outlining procedures for responding to emergencies, such as mechanical failures, accidents, or adverse weather conditions. Make sure that personnel are familiar with emergency protocols, including contacting emergency services and assisting those in need. Regular drills and scenario-based training exercises help prepare personnel to effectively respond to emergencies, fostering a culture of readiness and resilience within the team. Proper planning will ensure your construction equipment is moved safelyMoving heavy construction equipment safely requires careful planning, thorough preparation, and adherence to safety protocols. By following these top tips, you can minimize risks, protect valuable machinery, and warrant the safety of personnel involved in the moving process. Remember to conduct a risk assessment, inspect the equipment, use appropriate accessories, train personnel, plan the route, secure permits, monitor weather conditions, implement safety precautions, perform regular inspections, and have a contingency plan in place. With proper precautions and attention to detail, you can successfully move heavy construction equipment with confidence and peace of mind. Further Important Information: When construction equipment arrives on your project check these things. Construction Equipment Productivity What Size Equipment Is Right for Your Construction Project? AuthorBrandon Smith is a Family Affair Moving Orange County team member focusing on commercial moves and logistics. They are a long-lasting staple in the community, offering everything from commercial and residential moves, last-minute relocations, and loading and unloading services. Bringing a wealth of experience in project management, Brandon recognizes the critical importance of clear communication in facilitating smooth transitions throughout projects. This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?"This book helps with practical tips learned from real experiences. A must read book for the people who are involved in construction projects, especially project managers." Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. We will not enter into discussion on why a particular comment was removed.

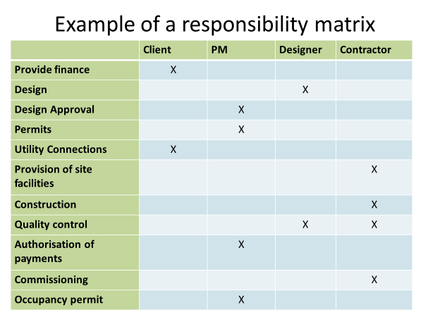

"Good communication is essential to the success of your construction projects." Effective communication within construction teams is the glue that holds together every aspect of a construction project. It ensures that it progresses smoothly and efficiently. In the intricate web of construction tasks, from planning and design to execution and completion, miscommunication can lead to costly construction delays, errors, and even safety hazards. Communication strategies in construction teams aren't merely a buzzword but an indispensable factor in the industry's success. Every message relayed, every detail clarified, and every issue resolved all contribute to the good operation of a construction project. In this article, we will explore the significance of clear and concise communication in construction teams and the strategies that can help bridge the gap between diverse roles and tasks. Join us to unlock the power of effective communication in the construction domain. Clear CommunicationClear and concise communication is the cornerstone of successful construction projects. When communication falters, the consequences can be dire. Specifically, misunderstandings, errors, and delays become commonplace, jeopardizing the project's budget and timeline. Further, unclear communication can lead to accidents and safety hazards, putting the well-being of the construction team at risk. To mitigate these issues, straightforward language is key. Conversely, using jargon or convoluted terminology can muddy the waters and create confusion. Instead, when construction team members communicate in plain and simple terms, everyone involved can easily grasp the message, reducing the likelihood of errors and misinterpretations. In the construction industry, where precision and coordination are paramount, the benefits of clear communication are crystal clear—smoother operations, fewer mistakes, and a higher likelihood of project success. Does Your Team Know What's expected From Them "With clear and honest communication, you can avoid many misunderstandings and difficulties." Construction Team MeetingsRegular team meetings are important in the construction industry, serving as a linchpin for effective collaboration. These gatherings are forums for sharing vital information and making sure every team member is on the same page regarding project objectives, progress, and changes. Also, team meetings offer a platform for resolving issues promptly. When challenges arise, they can be addressed collectively. This allows diverse perspectives to be heard and solutions to be devised collaboratively. You should follow some key tips to ensure that team meetings truly serve their purpose. These can include setting a clear agenda, maintaining punctuality, and encouraging active participation are among the hallmarks of effective team meetings. Incorporate these strategies and transform routine gatherings into effective team meetings that drive project success and foster a culture of open communication within your construction team. project staff meetings - are they adding value to your project? Use Digital Tools on your Construction ProjectsDigital tools play an important role in revolutionizing communication within construction teams. They offer a range of advantages that streamline project management and facilitate effective information exchange. Project management software, such as Trello and Asana, empowers teams to track tasks, deadlines, and progress in real time, ensuring everyone knows their responsibilities. At the same time, communication apps like Slack and Microsoft Teams provide instant messaging and file-sharing capabilities, promoting quick and efficient exchanges of information. Additionally, cloud-based platforms like Google Workspace and Dropbox enable seamless collaboration on documents and drawings, eliminating the need for cumbersome email chains. These digital tools enhance communication and centralize project-related data, fostering a more organized and efficient workflow. Can technology help your construction project? Roles and Responsibilities on the Construction Project Must be ClearWhen team members understand their roles and expectations, it prevents confusion and minimizes the risk of task overlaps. This clarity enables a more organized and efficient workflow, reducing the likelihood of errors and bottlenecks. For instance, a construction manager oversees the entire project, while an architect focuses on design aspects. A construction worker, on the other hand, concentrates on executing tasks on-site. In contrast, ambiguous or overlapping roles can lead to confusion, delays, and even disputes among team members. Role-based communication ensures that each individual knows who to report to, who to collaborate with, and how to communicate effectively within their sphere of responsibility. What does it take to manage a construction project? "When team members understand their roles and expectations, it prevents confusion and minimizes the risk of task overlaps." Feedback Loop

Conflict Resolution in Construction TeamsConflict is inevitable in construction teams, but effective communication is the key to resolving disputes and maintaining team harmony. Communication strategies in construction teams are critical when it comes to addressing conflicts. Effective communication allows team members to express their concerns, needs, and viewpoints openly. However, you must remember that conflicts can also arise due to miscommunication. Therefore, clear and precise communication and active listening play a pivotal role in conflict resolution. Strategies for handling disputes include staying calm and composed during conflicts, focusing on the issue at hand rather than personal differences, and seeking compromise or alternative solutions. Regular team meetings and feedback sessions can also provide opportunities to address conflicts proactively, preventing them from escalating. Ultimately, embracing effective communication strategies fosters a collaborative environment, helping construction teams navigate conflicts and maintain their efficiency and cohesion. Conflict Resolution and Prevention on Construction Projects "Conflicts and disagreements can easily occur in the stressed world of construction, but you must manage and promptly resolve issues before they destroy the team and the project." Training and DevelopmentTraining for communication skills is a vital investment that can yield substantial benefits. Construction projects can enjoy improved coordination and collaboration by equipping team members with effective communication tools. Investing in training allows individuals to better understand the nuances of communication, from active listening to conveying messages. As a result, team members can express ideas and concerns more effectively, reducing misunderstandings and conflicts. Honed communication skills enable teams to adapt to changes swiftly, respond to challenges more efficiently, and foster a positive and productive working environment. In construction where precision and teamwork are essential, training for communication skills emerges as a crucial element in ensuring construction teams perform at their best. Training and mentoring in construction Good Communication is Essential for Successful Construction ProjectsIn conclusion, the significance of communication strategies in construction teams cannot be understated. We've explored the critical role of clear and concise communication, the benefits of regular team meetings, the empowerment of digital tools, the importance of defined roles and responsibilities, the value of creating a feedback loop, and the role of communication in conflict resolution. Moreover, we've highlighted the transformative power of training for communication skills. Effective communication is the linchpin that holds construction projects together, ensuring efficiency, minimizing errors, and fostering a collaborative atmosphere. We encourage you to implement these strategies, enhancing your team's communication and, ultimately, the success of your projects. Don't miss the chance to build better with better communication. 12 important phrases to use in construction the importance of good communication on projects #constructionmanagement #constructionprojectmanagement #construction AuthorLucy Tray is an experienced professional at Hansen's Moving and Storage CA specializing in commercial moves and logistics. With a background in project management, Lucy understands the pivotal role of effective communication in ensuring seamless transitions during projects. This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?"This book helps with practical tips learned from real experiences. A must read book for the people who are involved in construction projects, especially project managers." Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. Note: We welcome genuine comments, especially comments that add additional information to the subject matter in the article. We however reserve the right to remove inappropriate comments, which includes comments that have nothing to do with the subject, comments that include inappropriate language, and comments that are an advertisement for a product or company, or which include an advertising link. We will not enter into discussion on why a particular comment was removed.

"Unpredictable elements like heavy rain can pose significant challenges to construction projects" Navigating the complexities of managing construction projects in extreme weather conditions requires a strategic approach. Unpredictable elements like heavy rain, snow, high winds, and extreme heat can pose significant challenges. So, let’s review the strategies and solutions to ensure the success of your construction endeavors despite them! Preparing your construction project for extreme weatherPreparing is a vital aspect of managing construction projects in extreme weather conditions. With the unpredictability of climate patterns these days, it's better to plan ahead. Historical weather data analysis can offer valuable insights into the specific risks your region faces. Developing flexible timelines and contingency plans within your budget is a smart move, too. Don't make these scheduling (programming) mistakes Finally, investing in weather-resistant materials and adapting your equipment for extreme conditions can save you time and money. Safety measures for your construction workersSafety measures for workers are a necessary component of managing construction projects in extreme weather conditions. Prioritizing the well-being of your team ensures their health and contributes to the project's overall success. Thorough training and education are key to achieving this. Workers should be well-versed in safety protocols and emergency response procedures. This will help them react effectively in any unforeseen situation. Equipping your team with the appropriate personal protective equipment (PPE), such as cold weather gear or heat stress prevention measures, is also a proactive way to minimize risks. Investing in worker safety demonstrates your commitment to their welfare and reduces the likelihood of accidents and delays. "Equip your team with the appropriate personal protective equipment (PPE)." Preparing your construction siteEffective site preparation is the foundation of a successful construction project. It involves several crucial steps to ensure a safe and efficient work environment. First and foremost, proper drainage and water management are essential to prevent flooding and erosion, which can wreak havoc on construction sites. You can safeguard your project from costly setbacks by implementing effective drainage solutions and erosion control measures. Additionally, in regions prone to snow and ice, it's imperative to have strategies in place for snow removal and deicing. Clear snow promptly and ensure safe pathways for workers, too. A well-prepared site sets the stage for a smooth and efficient construction process, minimizing delays and unexpected challenges. Avoiding weather related project delays Weather monitoring and forecastingWeather monitoring and forecasting will always be a simple yet accessible way to protect your construction site. You can stay ahead of changing conditions by utilizing advanced technology, such as weather apps and on-site weather stations. Real-time data empowers you to make solid decisions, allowing for timely adjustments to schedules and workflows. Effective communication with project stakeholders, including suppliers and subcontractors, is also facilitated through accurate weather information, helping you maintain project timelines and budgets. Whether it's adapting work schedules to avoid heavy rain or ensuring workers' safety during scorching heatwaves, weather monitoring and forecasting are indispensable tools in the construction industry. Changing seasons - is your construction project ready? "Weather monitoring and forecasting are indispensable tools in the construction industry." Communication and coordinationKeep everyone in the loop, from team members to subcontractors. Regular meetings create a platform for sharing updates, addressing concerns, and aligning goals. Clear communication channels also ensure that information flows seamlessly, reducing misunderstandings and delays. Collaboration between team members and suppliers further fosters a sense of unity, making it easier to tackle unexpected challenges. Suppliers and subcontractors should be well-versed in contingency agreements, too, ready to step in when needed. This synergy, where everyone knows their part, results in a harmonious and efficient construction project. Therefore, embracing effective communication and coordination practices helps conquer adverse conditions, ensuring your project stays on track and within budget, regardless of the weather. the importance of good communication on projects Temporary structures and shelterTemporary structures and shelter are invaluable assets in construction projects, especially when extreme weather conditions threaten to disrupt operations. These structures, such as tents and canopies, provide a refuge for workers, shielding them from rain, sun, or snow. They also serve as protective cover for materials and equipment, preventing damage and costly replacements. In extreme cold or heat, heated or cooled spaces can maintain workable temperatures, ensuring the safety and comfort of your team. These temporary structures are like the fallbacks of your construction, quietly supporting productivity and reducing the risk of weather-related delays. Therefore, investing in these practical solutions safeguards your project and demonstrates your commitment to worker well-being. "Temporary shelters can facilitate work even during adverse weather conditions." Impact on project budgetManaging costs of construction projects are a delicate balance, and extreme conditions can significantly impact your project budget and timeline. When facing heavy rain or snow, additional labor may be required for cleanup and adjustments, which can strain your finances. Costs can also escalate due to the need for specialized materials and equipment capable of withstanding extreme conditions. Adequate insurance coverage is crucial, as it safeguards your investment and helps manage unforeseen costs associated with weather-related damages. Legal and contractual protections are equally important, providing a safety net in case of disputes or project interruptions. Don’t Screw Up Your Construction Insurance Claim! "Equipment parked up because of poor weather is costly and causes delays." Environmental considerationsEven when managing construction projects in extreme weather conditions, you must prioritize environmental considerations. Sustainable construction practices reduce the ecological impact and enhance the resilience of your project. Additionally, minimizing the ecological impact by protecting natural habitats and implementing effective runoff and pollution management measures is essential. While extreme conditions can present challenges, adopting environmentally responsible practices is an ethical choice that benefits both the planet and your construction project. Ensuring your construction project's success in the face of any weatherMastering the art of managing construction projects in extreme weather conditions is a testament to adaptability and foresight. Implementing the strategies discussed throughout this guide can help you mitigate the risks associated with adverse weather and ensure the smooth progression of your projects. So, you can ultimately boost your success despite the unpredictable forces of nature! Is Your Project Ready For Winter? Prevent poor weather from disrupting your construction project AuthorJames Thistlethwaite is a logistics expert at packandgomoversny.com, a trusted local moving and storage company in NYC. He orchestrates seamless transitions with unparalleled expertise and precision. With a passion for optimizing every move, James ensures that even the most complex relocations or projects are executed flawlessly! This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down. Do you want to learn how to manage construction projects successfully?"I highly recommend this book be read by all newly qualified construction project managers as well as those more experienced." Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights.

Visit to read more. The books are available in paper and ebook from most online stores including Amazon. "There are many different stakeholders involved with every construction project." If you want your construction project to go well, you can’t do without leveraging all your resources. And in turn, you can’t do that without your stakeholders. So, it’s crucial to understand the importance of stakeholder management in project success. Defining stakeholders in construction projectsIn construction projects, stakeholders encompass a diverse group, including owners, investors, local communities, regulatory bodies, designers and contractors. Moreover, each party holds distinct interests and wields potential influence over project outcomes. So, identifying these stakeholders early is vital, guiding project decisions and ensuring alignment. Additionally, understanding their roles, needs, and concerns helps prioritize actions for successful collaboration. Finally, by defining and involving stakeholders effectively and acknowledging the importance of stakeholder management, construction projects gain a solid foundation for success! "You need to always keep a careful eye on the needs and demands of key participants!" Recognizing the impact of stakeholders on project successIn the realm of excellent construction project management, recognizing the importance of stakeholder management is paramount. Stakeholders, ranging from owners and investors to regulatory bodies and local communities, possess the potential to shape project success significantly. So, their input and influence can affect timelines, budgets, and overall outcomes. Moreover, neglecting their needs may lead to costly delays or even project derailment. So, by acknowledging this impact, project managers can strategize effectively, engaging them in a way that aligns goals and minimizes conflicts. Create a comprehensive stakeholder list for your construction projectCrafting a comprehensive stakeholder list in construction projects is a fundamental step toward success. So, identifying all potential stakeholders early on lays the groundwork for effective engagement. Moreover, this list should encompass a wide spectrum, ranging from project owners and investors to local communities and regulatory authorities. Ensuring inclusivity guarantees that no influential party is overlooked! Methods such as surveys, interviews, and stakeholder mapping assist in compiling an exhaustive list. So, by meticulously identifying stakeholders, project managers can tailor their strategies, proactively addressing diverse interests and minimizing risks. Prioritizing stakeholders and their needsPrioritizing stakeholders and their needs is a critical facet of effective project management. So, categorizing stakeholders based on their influence and interest helps allocate resources efficiently. Moreover, balancing conflicting needs through careful consideration ensures project alignment. And identifying key stakeholders and addressing their concerns builds stronger relationships and fosters collaboration. Finally, acknowledging the significance of different stakeholders' contributions avoids potential roadblocks. "With the right support, you’ll maximize the value you get out of your resources!" Effective communication is essential for construction project successFor effective management, just acknowledging the importance of stakeholder management is not enough. Effective communication strategies hold immense significance! Clear and transparent communication bridges understanding gaps among stakeholders, fostering smoother collaboration. This allows you to, for example, properly communicate things such as budgeting and cost management. Furthermore, tailoring communication methods to their preferences through meetings, reports, or presentations enhances engagement. And ensuring that information flows seamlessly helps prevent misunderstandings and minimizes conflicts. Finally, regular updates and progress reports maintain their confidence. And addressing concerns promptly and conveying changes in a timely manner nurtures positive relationships! A well-structured communication approach is a cornerstone of successful management, facilitating alignment and driving success. Successful construction demands good communication Build strong relationships with key stakeholders on your projectCultivating robust relationships with key stakeholders emerges is a pivotal strategy. After all, developing trust and rapport with these influential parties is essential for success. So, by actively addressing their concerns and valuing their input, a sense of collaboration and partnership is fostered. Such strong relationships enhance communication channels, enabling a smoother flow of information. These positive connections can lead to valuable insights and potential solutions to challenges that may arise. Managing stakeholder expectationsEffectively managing stakeholder expectations is a cornerstone of successful project execution. Firstly, setting realistic goals and defining the project scope helps align everyone's understanding. So, consider using tools such as estimation software to make this easier. Furthermore, disruptions are minimized by addressing potential concerns and clarifying uncertainties early on. And adjustments to expectations, if needed, can be discussed collaboratively, maintaining satisfaction. So, when stakeholders feel their needs and expectations are acknowledged and met, a smoother journey is assured, reducing the chances of conflicts and enhancing overall work effectiveness. "Always have the latest data on all the developments at your fingertips!" Dealing with conflict and resistance on construction projectsNavigating conflict and resistance is integral in the realm of management. So, addressing potential conflicts of interest among stakeholders and managing opposition with strategic approaches is crucial. Here, effective communication is once more key to understanding underlying concerns and finding common ground. And open dialogue helps in defusing tensions and mitigating potential disruptions! Embracing a problem-solving mindset and seeking compromise also fosters collaboration and prevents impasses. Moreover, proactively addressing resistance can lead to innovative solutions and improved relationships. Stakeholder engagement throughout the project lifecycleMaintaining stakeholder engagement throughout the project lifecycle is pivotal for success. So, involving them from planning to completion ensures alignment and feedback incorporation. Moreover, regular interactions and updates keep parties informed and prevent misunderstandings. And adjusting your engagement strategy as the project evolves accommodates changing needs. Their input also aids in identifying potential risks and opportunities at every stage! So, collaborative decision-making fosters a sense of ownership and commitment. construction project meetings with your client Monitoring and feedback mechanismsImplementing robust monitoring and feedback mechanisms is another thing vital for management success. Regularly assessing progress and gathering feedback provide insights into stakeholder satisfaction and potential improvements! These mechanisms also help identify deviations from the plan and promptly take corrective actions. So, by continuously evaluating performance, managers can make informed decisions to maintain alignment with expectations. Tools like progress reports and surveys assist in gauging sentiment and capturing valuable suggestions! Moreover, utilizing this information aids in adapting strategies and enhancing project outcomes. So, effective monitoring and feedback mechanisms serve as proactive measures to address issues, ensuring that projects stay on track and stakeholders remain engaged and content throughout them. The long-term benefits of effective stakeholder managementEffective stakeholder management in projects yields substantial long-term advantages. Strong relationships fostered through open communication lead to future collaborations and opportunities. Engaged stakeholders can also become advocates, directing to new projects and partners. And positive connections established can contribute to a project's reputation and credibility in the industry. Moreover, satisfied stakeholders might provide valuable insights and expertise for future endeavors. Finally, well-managed stakeholder networks enhance a manager's professional network, creating a platform for continued growth and learning! So, over time, investing in stakeholder management bolsters a company's standing, aiding in securing contracts and partnerships. In essence, the benefits of skillful management extend far beyond the current work’s completion, positioning organizations for ongoing success. Why good relationships are important in construction Good Relationships are Important in ConstructionWith what we covered on the importance of stakeholder management in project success, it’s easy to understand why it’s so highly valued. It can make or break any construction, making things so much easier! So, make sure always to cherish and nurture such important relationships. What qualities does a good construction project manager require? AuthorJohn Mitchell is a management expert at müv | Trusted Florida Movers. With a wealth of experience in project coordination and stakeholder engagement, John has played a pivotal role in ensuring successful and seamless moving operations. And he loves to share the tips he's picked up through informative and comprehensive articles! Do you want to learn how to manage construction projects successfully?"The tips included in this book are arranged and structured in a very good way. Very useful book for construction practitioners." (Reader Amazon.com) Paul Netscher has written several easy to read books for owners, contractors, construction managers, construction supervisors and foremen. They cover all aspects of construction management and are filled with tips and insights. Visit to read more. The books are available in paper and ebook from most online stores including Amazon. This article is a guest post and the owners of this website take no responsibility for the content or it's originality. The website publishes this article in good faith with the undertaking from the author and supplier that the content has not been plagiarised. Please report any errors in the article to the website owners. Should you prove the content is not original the article will be immediately taken down.